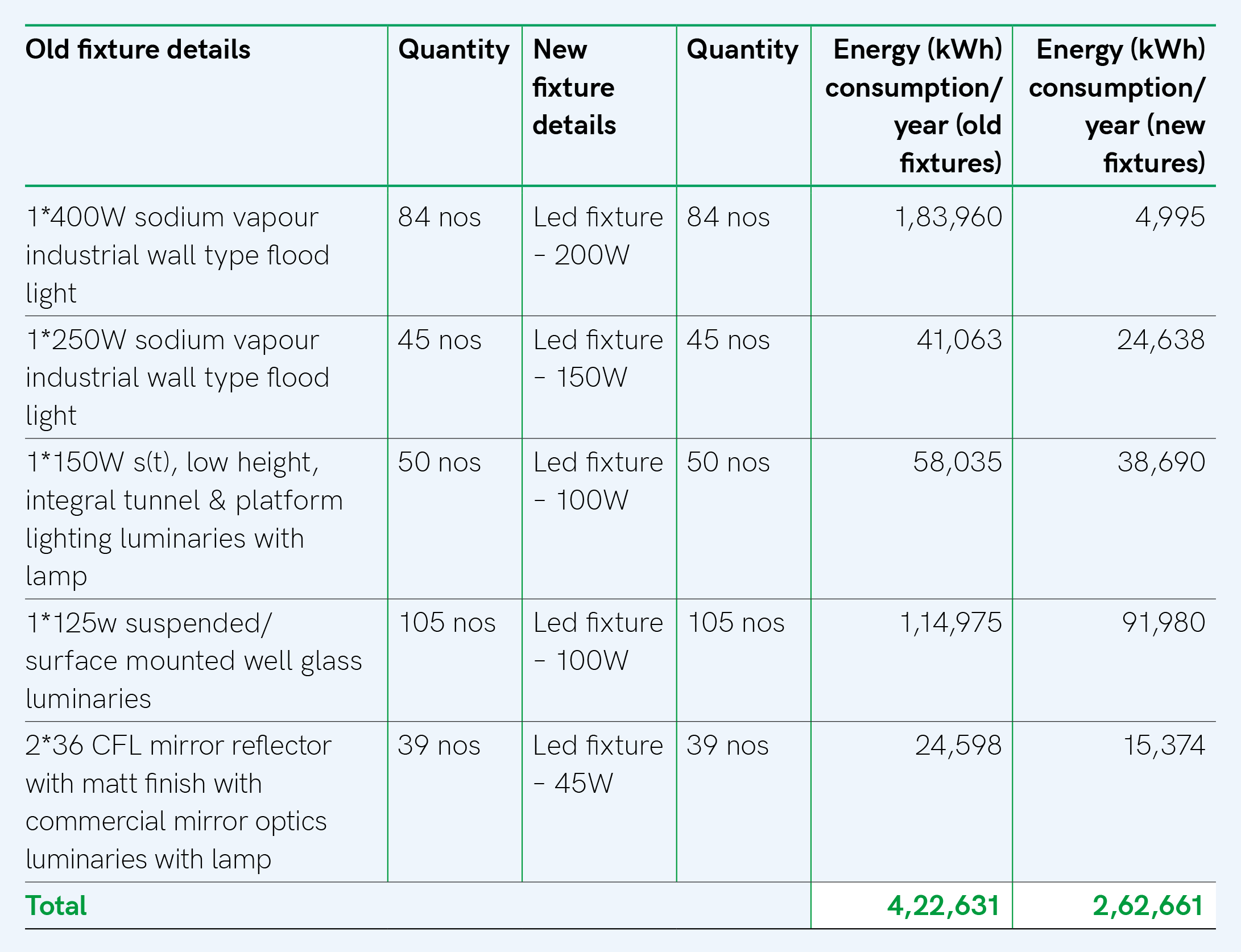

In an effort to reduce auxiliary consumption conventional Sodium/Mercury lamps were replaced by LED lamps at Dikchu HEP. The replacement was done in the Control room, Machine hall, Generator floor, Turbine floor and Transformer cavern. The project team had to engage the employees to understand work processes and lighting requirements under various scenarios. Impact on safety due to any visibility challenges were addressed.

This initiative has reduced the auxiliary consumption of the plant significantly as also reduced maintenance cost and improved aesthetics.

During the rainy season, heavy trash coming in the river water from the catchment was getting deposited in front of Trash racks at Intake, choking the trash rack and slowly was reducing water intake into the system. Cleaning the trash rack by engaging under water divers after shutdown used to cause loss of time and reduce efficiency.

In order to address this challenge and to improve plant load, Trash Rack Cleaning Machine (TRCM) was installed which prevents chocking at intake.

With the installation of TRCM, trash cleaning / removal is faster, safer, & without major shutdown, thus minimizing the outage of units and minimizing entry of trash and foreign material into Turbines.

With reduction of stoppage time, the total generation of the plant increased. An additional 1.43 MU was generated in FY 2018-19 compared to 2017-18. Also, about Rs.430 million was saved during the financial year owing to the initiative.

Summary of Generation Loss for Trash Rack Chocking Problems

This initiative has been implemented in Sumez, Jogini & Bhilangana plants of Greenko. Prior to intervention, in case when units were running at full load, when 33KV lines trip then turbine units also used to trip. The next start was possible only after the machine comes to a stand still, that is to zero rpm. This Run-Down Time from 750 rpm to 0 rpm was 16 minutes.

. In order to reduce unit’s start time and to increase machine availability, a modified PLC logic was implemented such that, after the unit trips, it will be kept at rated speed such that it is ready for re-start without waiting for run down to zero speed.

This modification has significantly reduced the unit waiting time from16 min to 4 min.

GEPS is an in-house built state of the art project monitoring system tailored for project management, QA/QC, engineering, logistics, material management, & stores. GEPS is the means of communication for drawings that can be downloaded/viewed from anywhere and any source (Tab/System) thus eliminating the need for emailbased file transfer. GEPS is the first-hand information to the management, it helps to identify the criticalities of the project execution in the stipulated timeline. The system helps the company to identify the severity of the critical activities by representing each activity in different color codes (5 different colors) w.r.t to a predefined program where each color represents the stage of completion of the activity against its stipulated timeline. GEPS contains Business Intelligence System and can be accessed by the management. This facilitates tracking and monitoring to the micro-level with highlighted criticalities based on the project timeline. Another function GEPS provides in Document Management System (DMS). When drawings are uploaded with the latest revisions and tags, the tagged personnel are notified through mail. This system helps mainly in reducing the need for emailbased communication thus avoiding miscommunications for site and HO teams.

To achieve the goal of reaching 30 Billion Units electricity platform by 2023, Greenko will progressively expand its asset portfolio in the coming years. Deployment of PPS will strengthen processes across operations. The focus on cost optimization through technology deployment and new partnerships for spares and maintenance will continue. Further, it will execute utility scale, schedulable renewable power generation projects that are first of its kind. This will be achieved through skill acquisition, new processes and systems and qualitatively different partnerships.