To become a utility-scale, flexible, round-the-clock power generator with customer-centricity, it is imperative that the company focuses on Innovation for differentiating itself from the competition, while continuing with continuous improvement in every sphere; adopting management systems; and extending standard operating practices to all activities.

Further, the recent initiatives of "Ownership at all levels" and "PPS- The GREENKO WAY" have strengthened processes and innovation.

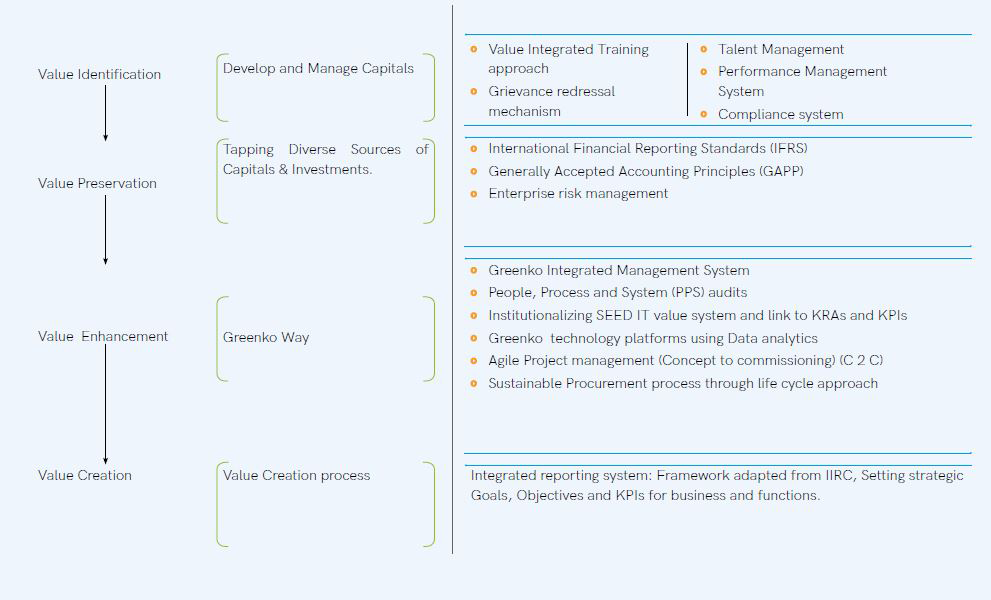

Greenko’s transformational journey to GKO 4.0 and its ability to deliver reliable and affordable power on a long term depends upon its ability to achieve continual improvement to adapt in the fast-growing sector, adopt new technologies to tackle challenges and to harness diverse business opportunities and actively innovate to differentiate.

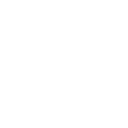

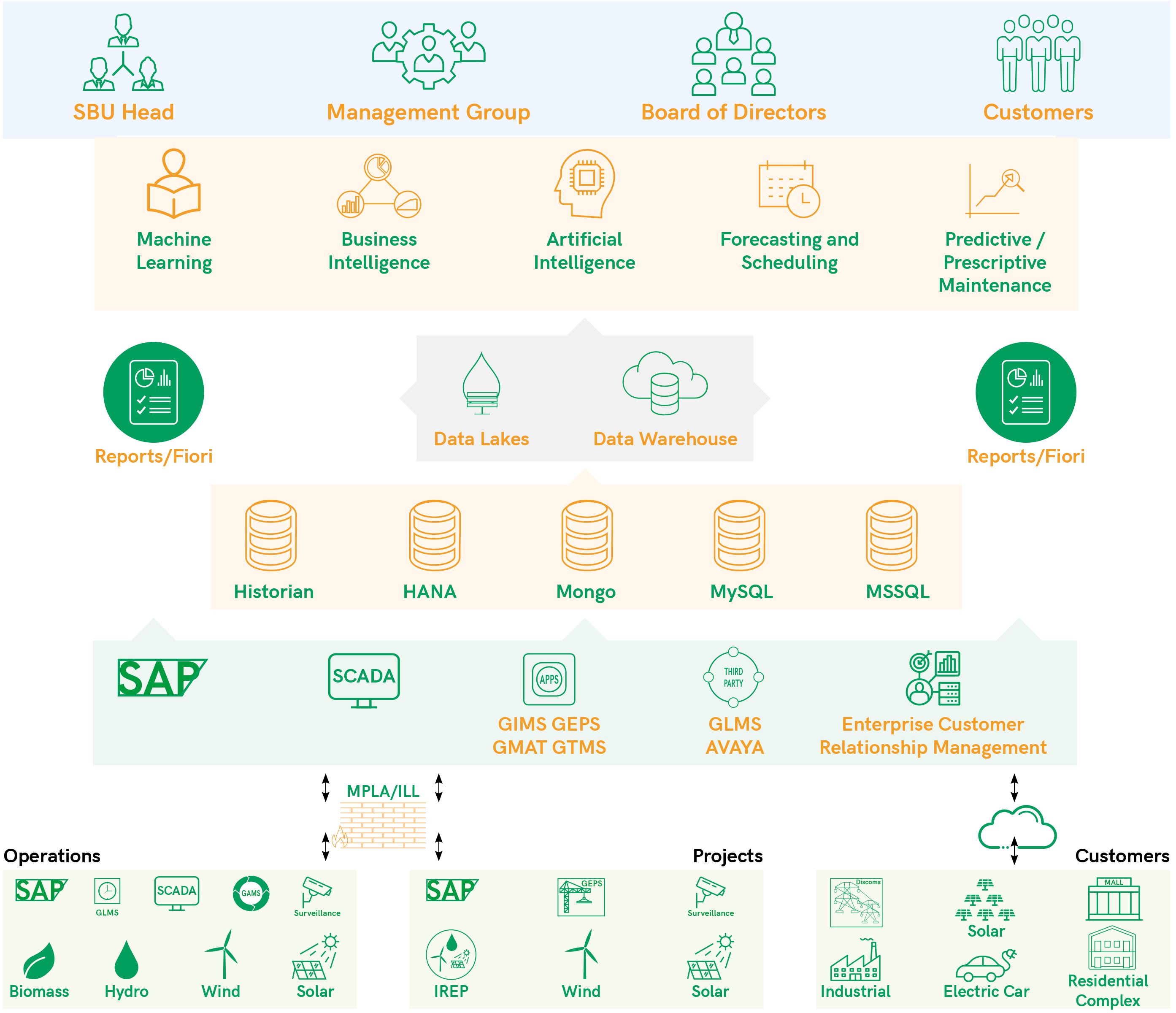

Greenko has developed and deployed Integrated management systems across its operations to standardize, achieve robust information management and sharing, monitoring and controlling systems, forecasting and scheduling delivery, document management and surveillance.

Audits are conducted to ensure adherence and effective outcome from the deployed management systems. The IMS audits conducted are both internal and external. In the reporting period, contributing to the continual improvement, corrective actions were taken for all the audit observations.

Besides the adoption of advances in generation technology, Greenko focuses on Information and Communication Technology (ICT) to improve operational efficiencies. The main objectives of Greenko’s ICT are as follows

Create new information management and analysis capabilities to assess risk in support of the Greenko’s supervisory responsibilities.

Ensure continuous availability of data / connectivity to various plant locations for real-time monitoring of assets

Improve information security and privacy protections against cyber threats and data breaches

Improve service delivery and timely response to new business requirements along with building new capabilities to serve long-term institutional improvements.

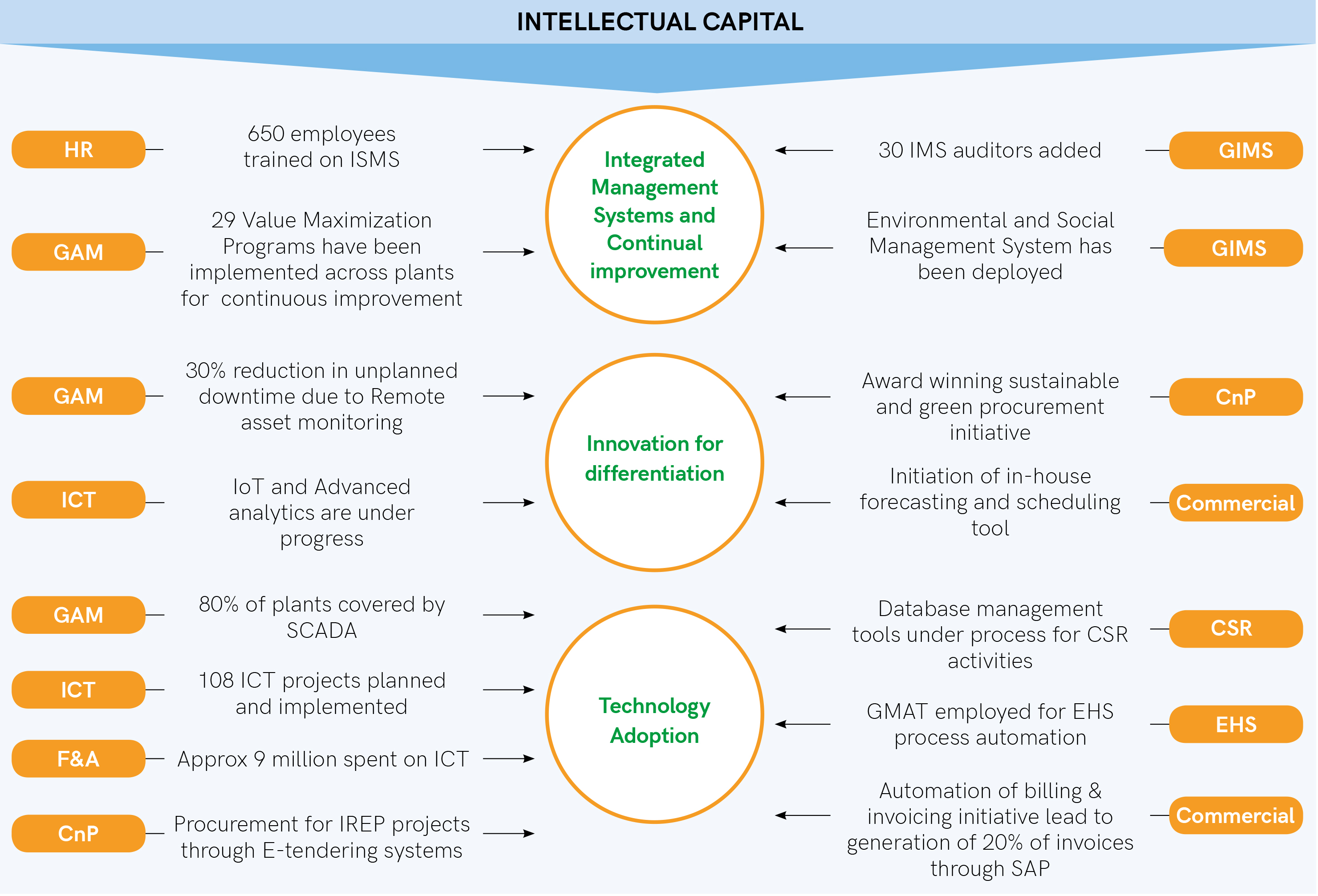

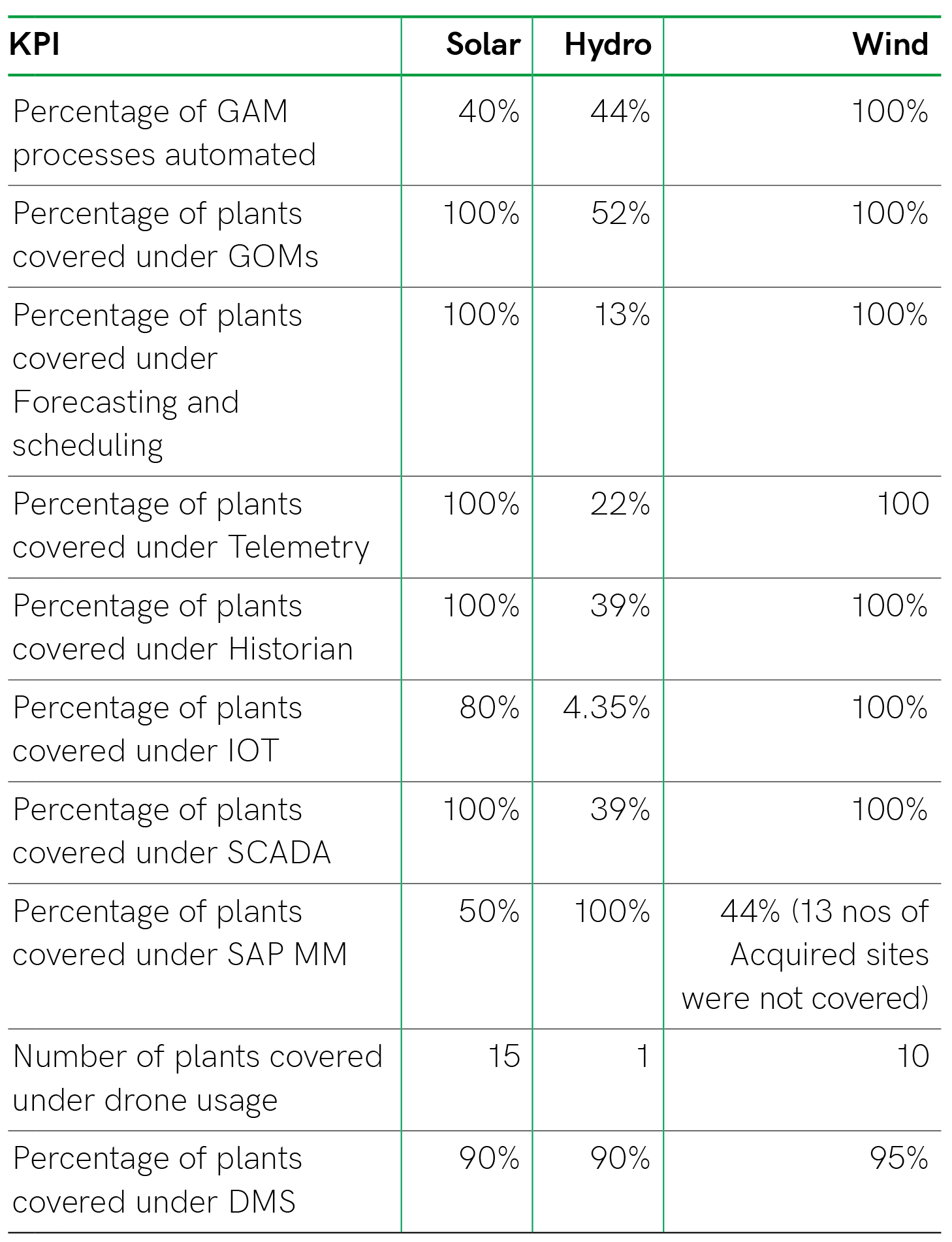

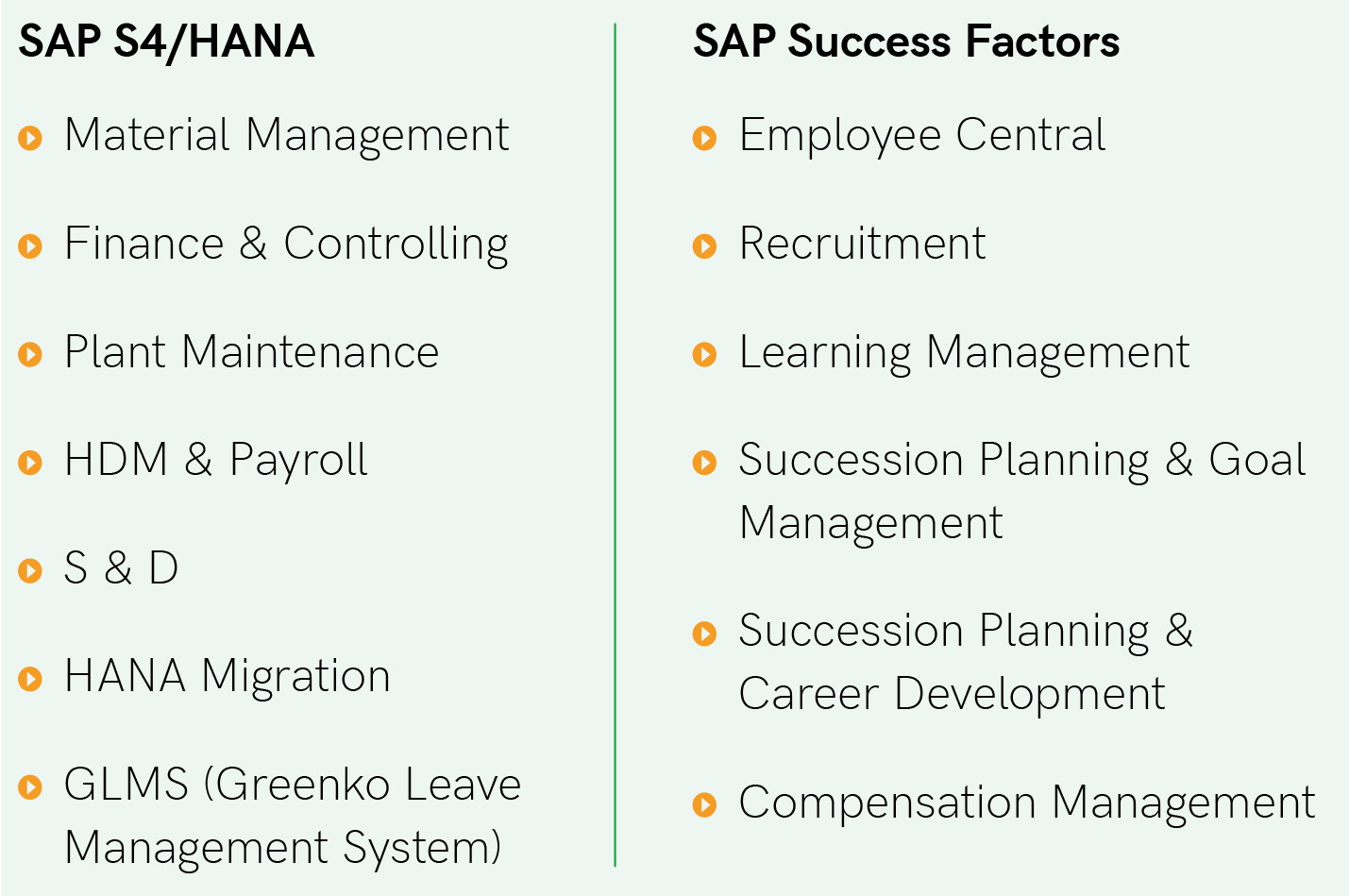

In the reporting period, 108 ICT projects were planned and implemented which constitutes16 GOMS projects, 11 SCADA projects and 81 Sap projects. ICT infrastructure of Greenko is continuously upgraded. In the reporting period, 85 networking towers, 789 CC TV cameras were installed. A total 1,424 of Greenko’s employees are email users and 30 Terabyte worth data is stored. Further IT security level is upgraded to Level 2: Proactive

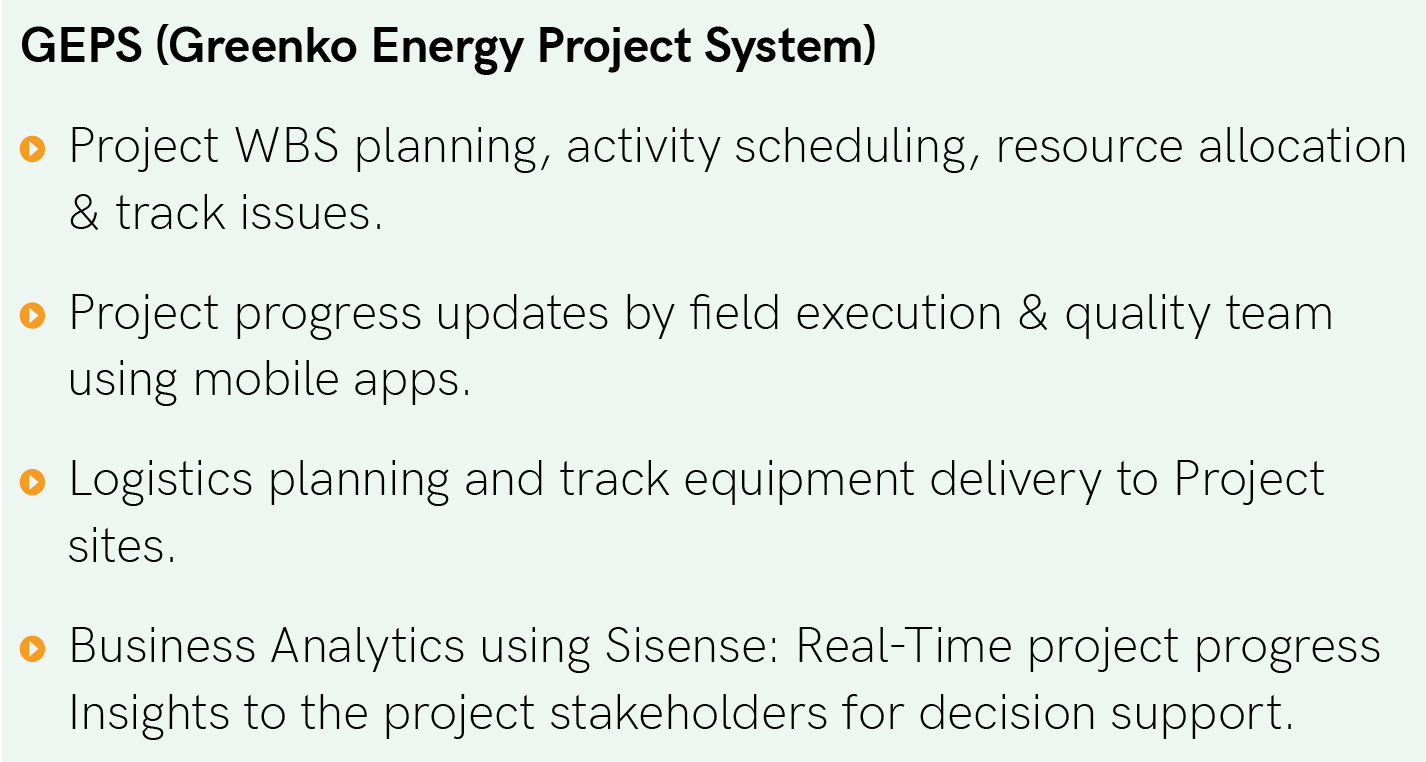

Greenko adopts new technologies, tools and instruments to achieve excellence in project management, plant operation and maintenance. Greenko plants are automated and the assets are monitored using IoT based state-of-the-art SCADA which enables centralized control and real-time monitoring of assets and troubleshooting. Bi hourly monitoring of remote assets has been established which significantly reduces unplanned downtimes.

Continuous improvement initiatives, value maximization programs and cost optimization programs were actively carried out among several Greenko projects.

1. Upgradation of automation – Budhil SCADA

2. Localization of Tracker material

3. Initiatives for maximization of energy across wind farms

4. IOT (Internet of Things) Implementation at upper Joiner

5. Plant efficiency Improvement and Water Conservation through MOCE

6. Forecasting and Scheduling

Budhil units were not operating at full overload due to non-commissioned systems, commissioned but nonfunctioning systems, lack of proper instrumentation and SCADA.

Old Version NARI SCADA EC 2000 replaced with the new version IMC- 2017

Commissioning of online Vibration Monitoring System & integration with SCADA

Plant Auxiliaries automation: - Auto operation of Plant auxiliary, UATs, SAT, LTAC breakers, DG Set, HP & LP Compressors, Drainage Pumps, Cooling water pumps & Booster Pumps

Integration of Plant auxiliaries PLC with main SCADA

Adding two Data Servers and a dedicated OPC server to the new SCADA system

Addition of flow sensors on water pipelines for feedback

Modification of the starter panels of Pumps and Compressors for making them compatible for REMOTE AUTO MODE and feedback

LT and HT switchgear Automation to avoid the manual operation and restoration in blackout condition

Modifications in operations logic of auxiliary systems which eliminates human error and manual operations

Ability to overload the machines up to 9%. (Approx. additional generation 8MU)

Increase unit capacity as forced outage due to incorrect operation of the equipment is reduced

Automation of Cooling Pumps and Booster Pumps helps efficient cooling of units and avoidance of unnecessary tripping owing to the feedback system

Automation of LT switchgear avoids the restoration of supply in case of Blackout and eliminates the scope of human error in manual changeover

Further, automation of drainage system helped to reduce the failure of pumps and eliminated the scope of human error in the operation of pumps

For Acquired tracker assets, oversees based OEM was not ready to supply individual parts. The mechanical components have been localized with competent vendors. Replacement of spares with new localized components across fleet.

Localized the spares for 1,000 No.s trackers across fleet which helped increase in Plant uptime and generation

Result:

with customized algorithm which increased the uptime and generation.

GAM wind implemented following initiatives in ensuring maximisation of energy.

In house WTG O&M activity has improved overall asset performance.

Preventive and condition-based maintenance practices through diagnostic tools has improved overall asset availability.

Transmission losses are minimized by adopting seasonal operational controls over wind farms.

Internal grid strengthening measures has improved overall wind farm availability.

Implemented additional safe measures in power panels to eliminate operational hazards like flash overs.

Overall wind farm blade reliability has been improved through proactive blade inspections and initiating corrective measures for anomalies on blades.

Adhering to 100% periodical and regular audit inspections has resulted improvement in overall asset availability.

Additional Leading-edge protection and Hydro wash for Blades has improved generation.

Effective IGBT maintenance management reduced component failures.

Enhancement of overall asset availability and performance

Overall asset health has been improved.

Result:

Gross generation was improved by 4%

MA & GA was improved by 0.5%

There was no “data connectivity facility at Upper Joiner”. IoT was implemented to transfer data to Corporate office - CMCS.

1. Industrial IoT Gateways for Monitoring Turbine, Generator, Governor & Exciter, Transformer & HT Panels, OPU & Neutral Grounding Panels, Temp Scanners & Discharge/flow sensors etc., - at configurable intervals.

2. Local Controls and Automation of Plant Start & Stop Sequences.

3. Monitoring Software running on Local Server in the Plant Control Room and Remote Server at Greenko headquarters or in Cloud, with SQL database and long term storage.

4. User access through browser based dashboards with alerts (on equipment or system faults & errors), Analytics and configurable reports in Excel format.

As a measure to improve plant efficiency as well as to reduce water consumption during module cleaning, an optimized module cleaning strategy was implemented employing the MOCE method at Ghani Solar Park, Kurnool.

The objective of the program was to develop an inhouse scientific approach for calculating the Soiling Rate of solar modules using SCADA’s real-time data so as to determine an optimal cycle time for cleaning of the module, thus increasing the plant’s efficiency and reducing water consumption.

Action taken

The optimal module cleaning cycle was determined using real-time data with respect to high yield loss inverters.

Impact

The implementation effectively improved generation by 2.5% and reduced water consumption by 25%.

Digital inspection of rotor blades using Drone integrated high-resolution camera is an advanced technique for reliability improvement. It is an effective alternative to have a closer look of the rotor blades. It is more reliable, cost-effective, faster to assess and has technological leverage over the traditional approach.

Using this technique, Greenko could avoid the accumulation of dirt on turbine blades which otherwise, leads to erosion and 3M tape damages. These interventions have increased the AEP from 3 to 5%.

Turbine blades’ health was analyzed, as a pilot, using drone system. The images were systematically reviewed and appropriate measures were taken. Seven WTG’s 3M tape blade application activity has been carried out during the reporting period. For dirt accumulated blades, corrective actions were carried out by employing a pressurized water pump.

The digital inspection of rotor blades increased performance of up to 5%. It also improved the aero efficiency of the turbine blades significantly.

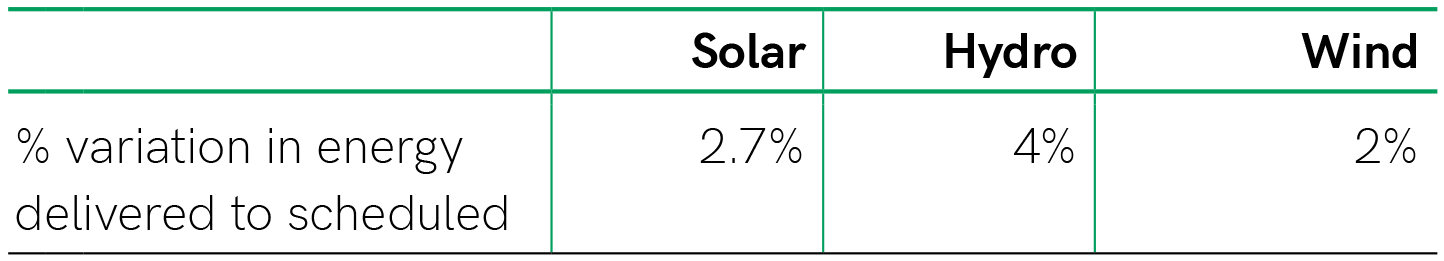

Forecasting demand and scheduling generation accordingly is essential to deliver flexible and reliable power, hence it is a significant initiative for the GKO 3.0 transformation. In order to meet the SLDC regulations Greenko has initiated in-house capabilities of resources and Infrastructure for forecasting and scheduling. Presently, F&S schedules are generated with the help of different forecasting agencies to deliver the SLDC’s requirements. We have partnered with three of the best forecasting agencies. Further at Budhil Hydro Power Greenko could achieve a reduction in deviation by 1.08%. The deviation was less than 4% in the schedule and the actual delivery of power in FY2018-19 increased by 5.08% in comparison to FY2017-18

Our efforts and deployment of technology has yielded encouraging results in delivering power as scheduled. This capability is indicative and forerunner to the business transformation designed to harness many new value pools in the energy sector.

In the face of basic infirmity in the underlying core generation technologies, integrating renewable energy sources with appropriate storages to provide firm power constituted our innovation pursuit for differentiation and competitive advantage. Such innovation included continuous improvements, marginal innovations, adoption of technologies and planning new and innovative projects. While Greenko makes big moves to address the challenges of future energy scenarios, it recognizes the significance and encourages the innovation culture. Greenko rewards innovation at all levels through a variety of innovation awards.

Information Security is imperative as digitalization is increasingly adopted by Greenko. Also, as it moves towards the Intelligent Energy Platform, information security will be more critical.

The scope of information security system extends to all information used at Greenko Group, in all formats, regardless of the specific departments and individuals that own and manage the information at a local level. This includes information owned or processed by other organizations but relevant in their dealings with Greenko Group. While the focus of information security capabilities is provided by the Information Security function, a number of additional departments including Legal and Registry include explicit information responsibilities and are therefore considered in Information security.

The Information Security function provides and coordinates expertise to influence the information security approach of the Greenko Group, helping it to achieve its strategic objectives by ensuring the availability, confidentiality and integrity of its information. By recognizing the different types of information used, and the business requirements associated with each, we will deliver a secure framework within which we can provide flexibility to suit organizational needs while maintaining compliance with legal obligations and sectorspecific best practice.

All operations at Greenko will be covered by PPS and this will supplement the GIMS and other certified management systems. The empowerment model to strengthen human capital will also add to intellectual capital. Further, digitalization of all Greenko projects to provide flexible, reliable and affordable power will be pursued progressively by increasing the percentage of its projects covered by automation, forecasting and scheduling, SAP, IOT etc.

Progressive implementation of Intelligent Energy Platform by piecing together existing digital advances on an adaptive and intelligent framework will be focus of our journey ahead.