Message from CSO

Dear Stakeholders,

This year has been disruptive and exciting.

Our robust business continuity systems

enabled us to continue our operations.

The pandemic, its consequent social and

economic disruption has offered unique

opportunity to the economy and society

to revisit the foundations. At Greenko,

we have harnessed this opportunity to

put together building blocks for the New

Energy Transition.

The ambition of Paris Climate Agreement

to limit the global warming to 1.5 degrees,

is driving governments, cities, businesses,

and entities at large to transition to a new

paradigm of energy, industrialization ,

production and consumption. Greenko’s

business model is designed to address this

challenge of deep decarbonization that

is inclusive, self-reliant, and ecologically

sustainable, in partnership with business

and government. Greenko’s three pillars of

Energy, Storage and Zero C Molecules’ Assets

support “Race to Zero” emissions and thus

avoiding cataclysmic social and economic

disruptions due to global warming beyond 1.5

degrees. Greenko’s solutions are curated for

transition away from fossil energy and carbon

chemistry with minimal reliance on carbon

capture and storage, thus ensuring just and

environmentally friendly transition. While the

business model and solutioning of Greenko

are aligned with sustainable development

pathway, we are sensitive to the need for

diligence and care during project planning,

execution and operations. Accordingly, we are

committed to Racing to Zero ourselves – ten

year’s earlier by 2040. We are signatories to

Climate Pledge and are working on a roadmap

along with our partners in the value chain

and co signatories of Race-to-Zero. In our operations gate-togate, the GHG footprint

is minimal, and we would ensure zero

emissions in the next few years. Our business

vision of Decarbonization, Digitalization and

Decentralization, requires us to grow our

energy, storage and Zero C Molecule assets

at a pace commensurate with our Net Zero

pathway. In this growth of assets, we will focus on low carbon input materials. While we

will be the catalysts in moving the ecosystem

along the value chain to decarbonization,

our ability to procure low carbon equipment

and machinery will depend on adoption of

decarbonization by countries, cities, and

Greenko’s business

directly contributes to

UNSDG 13-Climate Action

and UNSDG 7-Affordable

and Clean Energy and

UNSDG 12-Responsible

Consumption and

Production goals.

Greenko’s business

directly contributes to

UNSDG 13-Climate Action

and UNSDG 7-Affordable

and Clean Energy and

UNSDG 12-Responsible

Consumption and

Production goals.

businesses. Besides, climate stewardship

along the supply chain, we will adopt circular

approaches in the management of our assets

- extend the life of assets, sharing models and

recycle, reuse, remanufacture during and at

the end-of-life of assets, to fulfil our climate

pledge.

As we transition and grow, we will continue

to adhere to our diligence practices

of Environmental and Social Impact

Assessments (ESIA) at the stage of design of

our projects and interventions, Environmental

and Social Management Systems in our

operations, embedded in Greenko Integrated

management Systems. Further, during the

reporting period, we have developed the ESG

framework delineating our ESG priorities,

our position on each ESG aspect and thereon

objective and targets. Salient aspect of

the ESG framework is increased role of

the governance in stewarding responsible

environmental and social practices. The

climate stewardship and circular economic

actions are the fulcrum of our Environmental

pillar. The Diversity, Equity and Inclusion

(DEI), Health and Safety, Retention and

Innovation and Customer Relationship will be

the foci of the Social pillar. The Governance

pillar will have focus on increased Board’s

role in stewarding ESG and Enterprise Risk

management including Cyber Security.

In our last and this Integrated Report,

we have outlined the results of physical

and transition risk on our operations

and mitigation measures that we have

undertaken. Going forward, climate risk

as also material environmental and social

risks will be a constituent of our Enterprise

Risk Management and will be periodically

reviewed by the Board. The ESG objectives

and targets will be dovetailed into KPIs and

remuneration/incentive mechanisms.

Greenko platform is agile and can resile to

be fit-for-purpose. In March 2020, when

the pandemic hit India. Greenko set up a

Covid Response Task Force and prepared a

multi-pronged action plan to respond quickly

to the evolving situation. Identifying the

requirement of oxygen and understanding

the evolving situation, the Covid Task Force

activated its global supply chain relationships

and focused on strengths to bring in critical

oxygen support infrastructure and equipment.

The focus was on expeditiously procuring the much-needed oxygen cylinders, oxygen

concentrators medical grade liquid oxygen

plants and cryogenic oxygen containers. The

company airlifted over 1200 medical grade

10 liters Per Minute Oxygen Concentrators

and created over 1200 oxygen beds in

remote locations and saved thousands of

lives. The concentrators were distributed to

rural hospitals in coordination with the state

governments. Today the revival of a defunct

60 TPD medical oxygen plant in Hyderabad

which would be producing over 45 tons of

medical oxygen has enhanced the overall

capacity of Telangana by 40%.

At the workplace, we implemented

disinfection and social distancing practices

and provided workers with personal protective

equipment. Employees leveraged technology

to minimize personal contact, even in dealing

with external stakeholders’ like vendors,

contractors, suppliers, regulators and

customers.

Greenko’s business directly contributes

to UNSDG 13-Climate Action and UNSDG

7-Affordable and Clean Energy and UNSDG

12-Responsible Consumption and Production

goals.

We recognize that the planet is at the brink,

and we must re-envision our relationship with

nature. We contribute to the conservation and

restoration of nature at our sites and across

the interconnected planet.

We continued our IR journey to be a more

equitable, inclusive, and transparent

company. Across the enterprise, we held

more than 4 formal IR conclaves, certified

around 250 Sustainability Practitioners. Going

forward, we see challenges in achieving our

own ambitious climate goals which include

decarbonizing supply chain and managing

assets post its life. Further, we must engage

and partner with governments, policy makers,

regulators, and businesses in managing

energy transition and “Racing-to -Zero” to

decarbonize both energy and industry. We

look forward to your continued engagement

to strengthen the endeavour towards green

and safe “Our Common Future”

Dr. Rambabu Paravastu

Chief Sustainability Officer

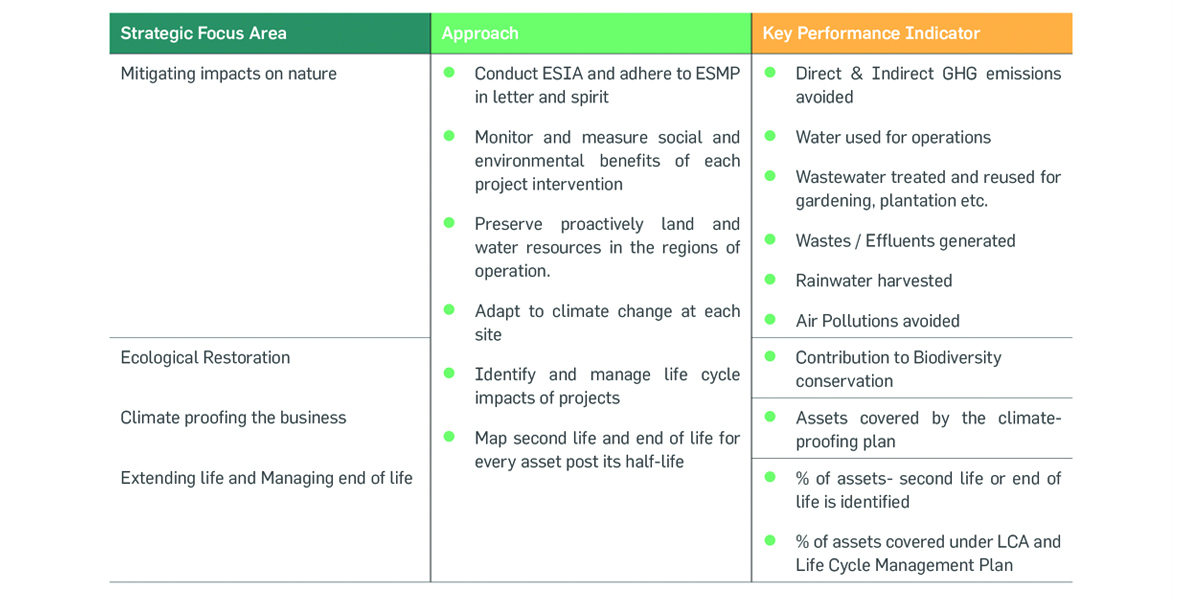

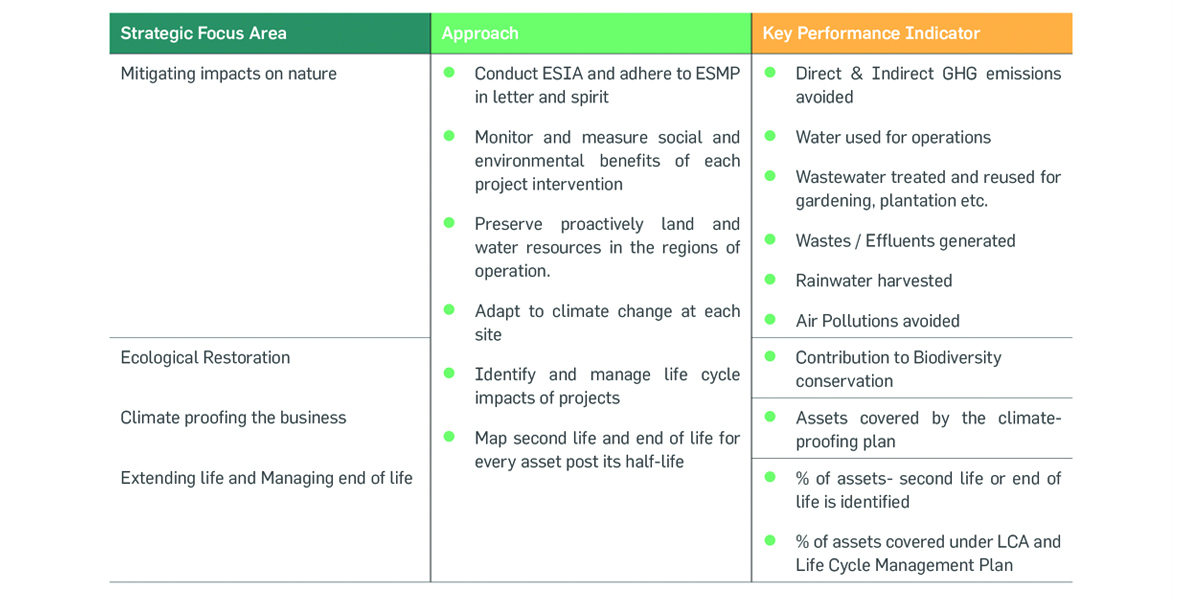

Strategic Approach

The business models of Greenko are closely integrated with value

generation from natural resources. Management of natural capital is always

embraced in Greenko’s decision-making process, risk mitigation plans,

strategic planning, and during the entire life cycle of Greenko’s projects

from design to operation and closure. The Group is in pursuit to extend

the life of the projects and assets by integrating such measures as a part

of asset management and also aspires to provide a second life for all its

assets to align with circular economy principles. Greenko is determined to

develop climate-resilient assets by periodically analysing the physical and

translational impacts of climate change on its project infrastructures.

The annual meetings at Greenko revolve around the discussions on shifting to a circular economy from take, make, waste models

and on circular resource management. Greenko has set up various short and long term goals to emphasize the actions to protect

and preserve natural resources. The environmental stewardship programs at Greenko are aimed at minimizing the operational

impacts, conceptualising business models in line with new climate normal and circular economy, protecting biodiversity, and

emphasizing digitalization across the operations as the first line of defense.

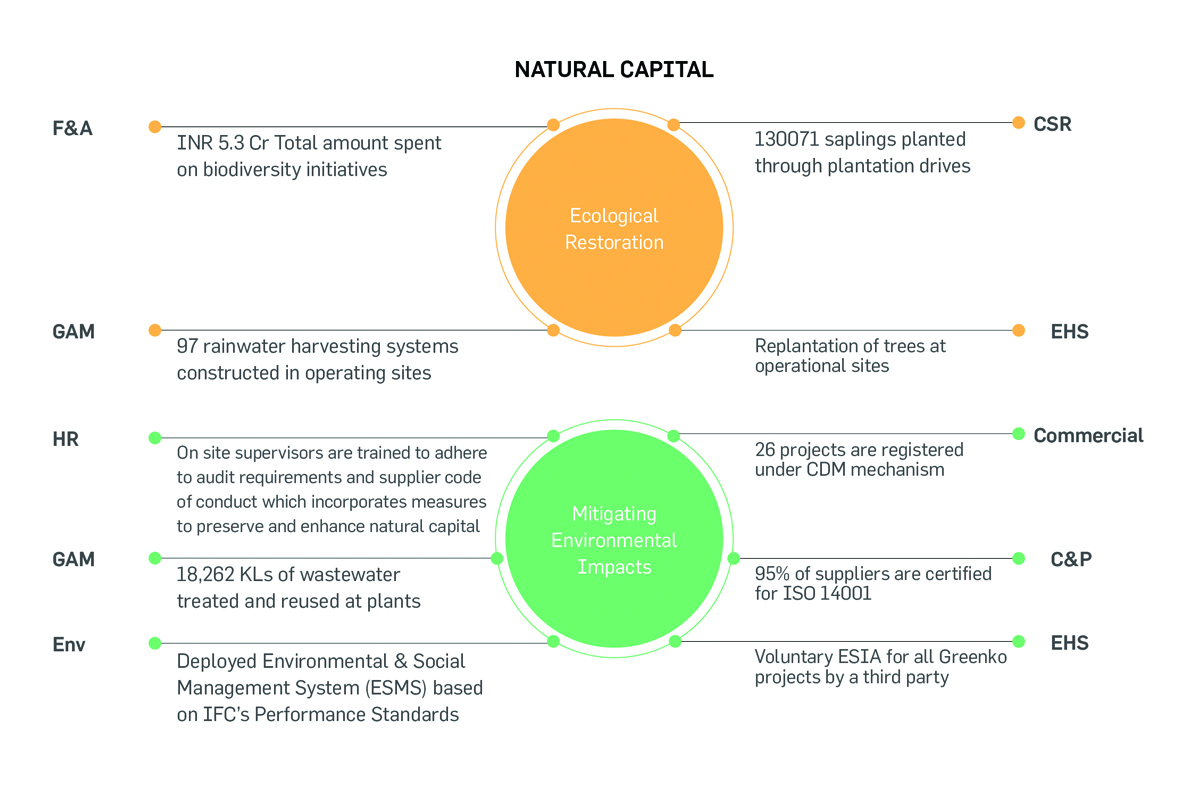

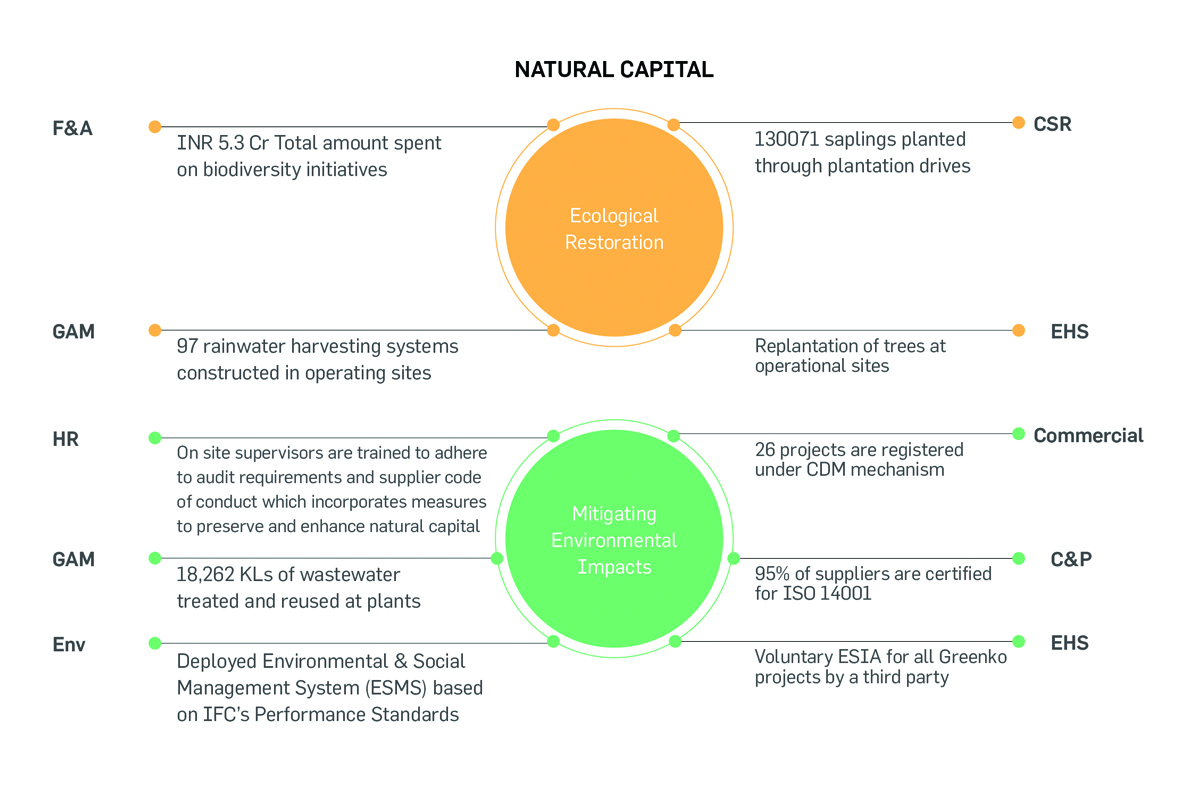

Integrated Value Creation in Natural Capital

Mitigating Impacts on Nature

Environmental Impacts & Mitigation Measures

Greenko endeavors to develop projects with minimum environmental impact

and thereby conducts preliminary assessment during the project planning

stage for promoting broader mitigation and conservation strategies. The

Group strives hard to understand the direct and indirect impacts of the

projects on the surrounding ecosystems and focuses to streamline its

operations efficiently to nullify the impacts to a great extent.

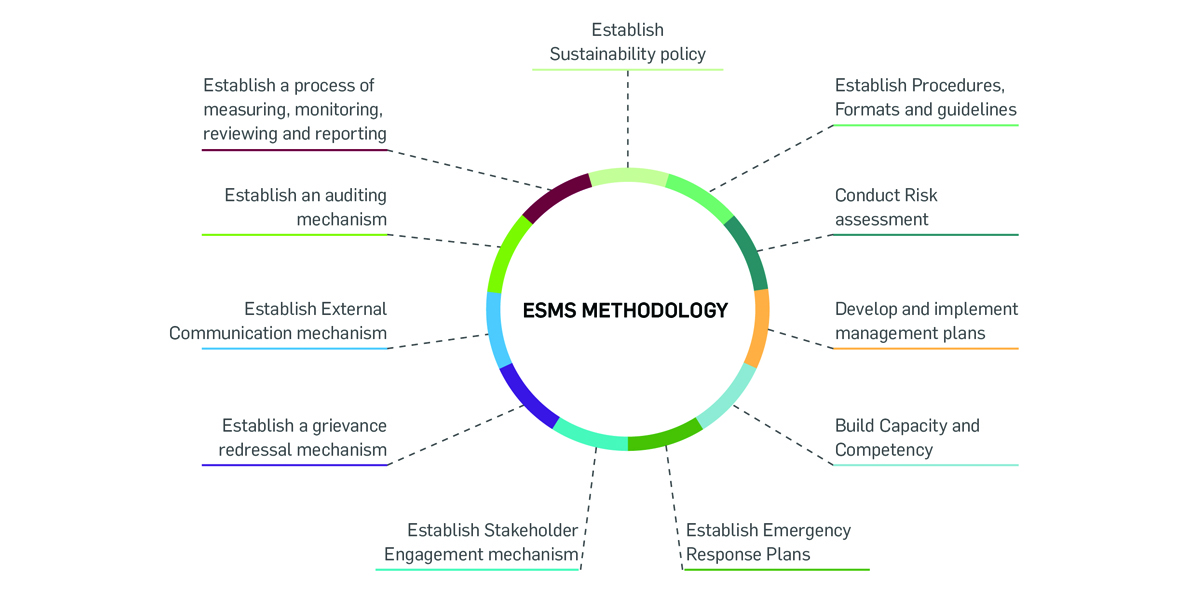

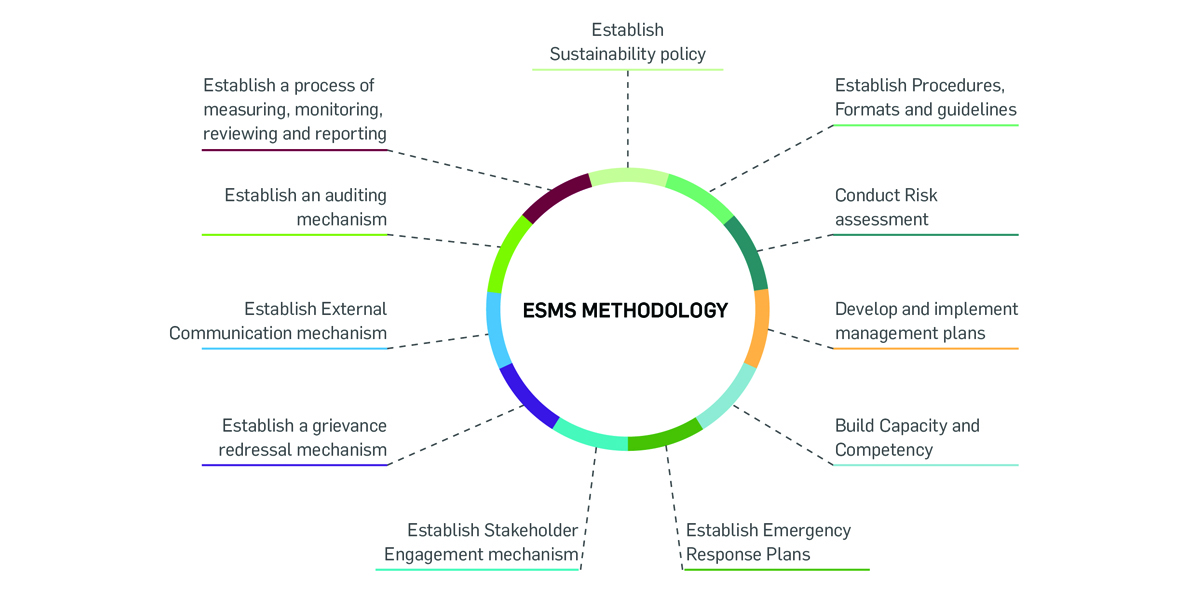

Greenko conducts Environmental and Social Impact Assessment (ESIA) study before project development, in line with the

requirements of ten Equator Principles; eight International Finance Corporation (IFC) Social & Environmental Sustainability

Performance Standards (PS); and IFC Environment, Health and Safety (EHS) Guidelines. This study helps the organization

proactively identify the adverse impacts of its operations on environmental resources. The impacts identified from ESIA study

are addressed through ESMP mitigation measures. Greenko adopts the following methodology for the implementation of ESMS.

ESMS progress during 2020-21:

- Revised ESMS manual and ESMS procedures.

- Implementation of ESMS in progress at 86 sites.

- ESMS training provided to 160 participants covering 3 SBUs and 1280 hours of training hours.

Responsible Sourcing

Greenko Group is combining its efforts,

expertise, and experience in improving the

sustainability characteristics of its supply

chain through its Green procurement

initiatives. The Group makes efforts to

procure green alternatives from suppliers by

continuously holding engagements with them

and by incorporating Ethical, Environmental,

and Social principles and values in its

procurement strategies. This initiative helps

Greenko to evolve a broader perspective

and to establish long-term cost-saving

opportunities. The major activities discharged

as a part of Green Initiatives are as follows

- Creating awareness among vendors/

suppliers on environmentally preferred

goods and services

- Making at least 95% of critical suppliers

ISO 14001 certified and RoHS compliant

by March 2024

- Inclusion of environmental specifications

and evaluation criteria as per emerging

technologies in centrally managed

procurement

- Developing a collaborative approach

to optimize information-sharing,

consistency and performance

measurement, and Life-cycle analysis

During the reporting period, Greenko

has accomplished significant progress

in responsible procurement of standard

equipment and appliances. This initiative also

helped Greenko to adopt energy-efficient

fixtures and guidelines. Further to this, proper

planning for transporting raw materials by

consolidating packages from various vendors,

has significantly reduced scope 1&2 GHG

emissions up to 50%. The internal movement

of logistics from warehouses to flight

loading areas is monitored and optimized

to reduce GHG emissions. Greenko also

ensured that its major suppliers (95% in all)

are upgraded to ISO 14001 certification and

are RoHS compliant. Greenko also includes

Environmental criteria and specifications in its procurement policy and creates awareness

among its vendors on environmental traits of

preferred goods and services.

Green Alternatives Procurement

- Procured Energy Efficient Equipment

including Energy Star labeled electrical

appliances

- Encouraged energy efficiency retrofits to

move towards securing a BEE (Bureau of

Energy Efficiency, India) 5-star rating

Green Initiatives

Initiatives to improve the circularity of solar assets

- Greenko Group has initiated discussions

with manufacturers of PV Modules and

Inverters, regarding the inclusion of

circularity and life cycle approaches

throughout their value chain.

- Purchase offer evaluation included circular value assessment during (description & details)

- After assessing PV module manufactures,

Greenko has placed orders on the merit of

life cycle assessment and management.

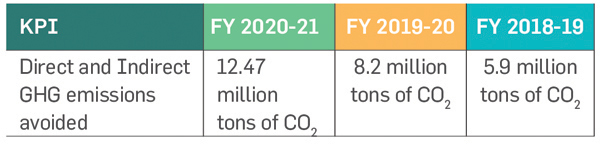

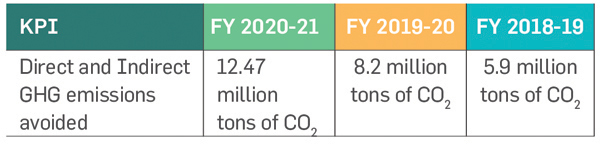

Contribution to Climate Change Mitigation

Through delivering

renewable energy to the grid

and open access customers

, Greenko has avoided 12.47

million tons of CO2 emissions.

In addition, the group has,

till date, registered 26 Clean

Development Mechanism

(CDM) projects with UNFCCC.

Greenko addresses

the physical climate

change impacts on its

business performance

and sustainability. The

Group makes imperative

efforts to mitigate and

minimize climate change

risks on stakeholder lives

and ensures promotion of

sustainable well-being.

The impacts of extreme

weather events like floods

and cyclones on the critical

power infrastructures were

studied in detail, and plans

to build climate-resiliency in

the operations of assets are

being implemented.

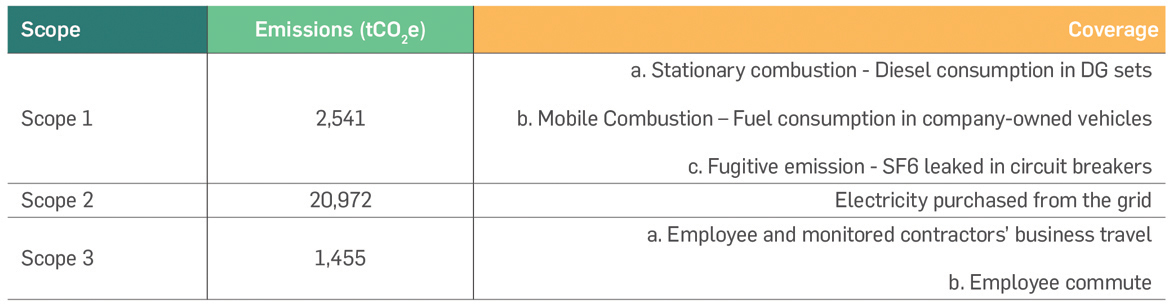

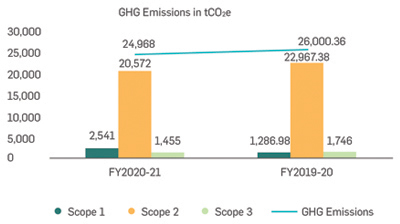

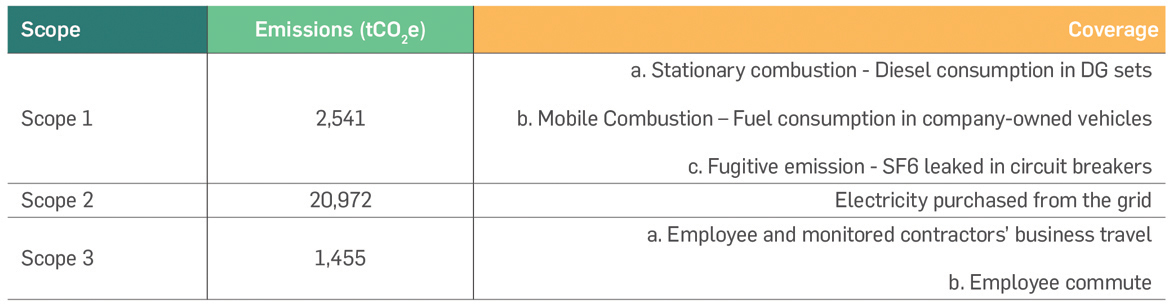

Direct and Indirect GHG Emissions

Scope wise GHG Emissions in last two financial years

The scope 3 emissions estimates are limited to only business travel and component. This obviously is a very small fraction of

scope 3 emissions. Greenko will assess and compute the scope 3 emissions covering all the 15 categories and report the same

in the next year report.

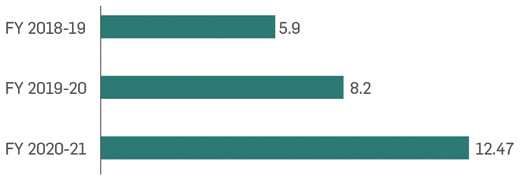

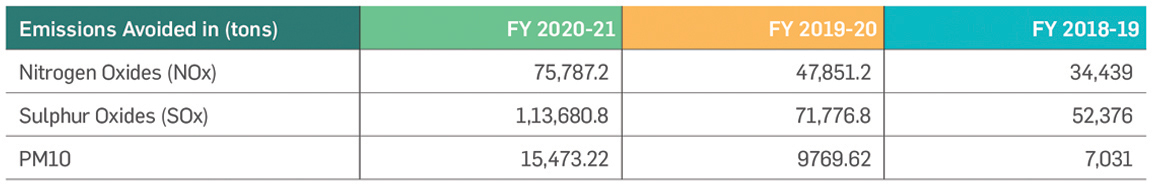

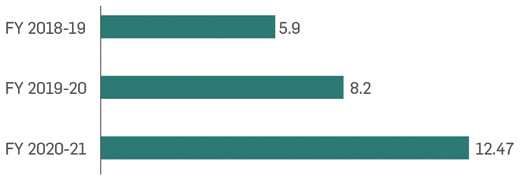

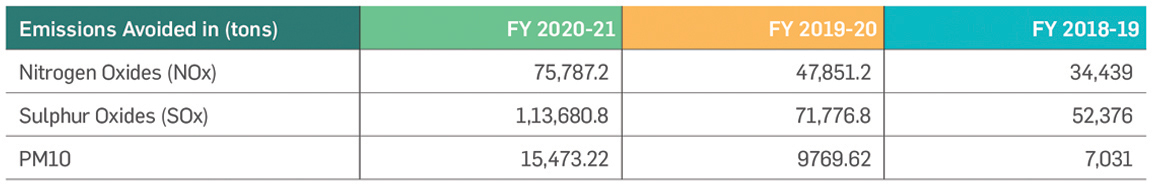

GHG emissions avoided

Direct and Indirect GHG Emissions avoided (in MtCO2)

Emissions avoided

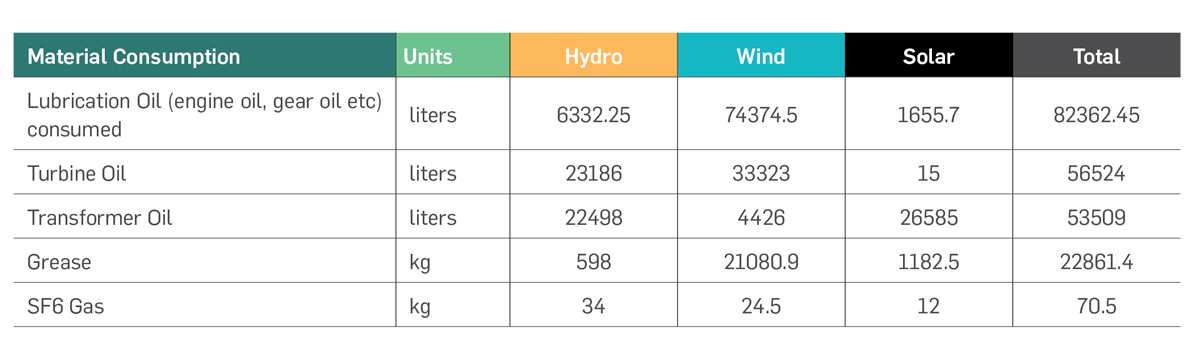

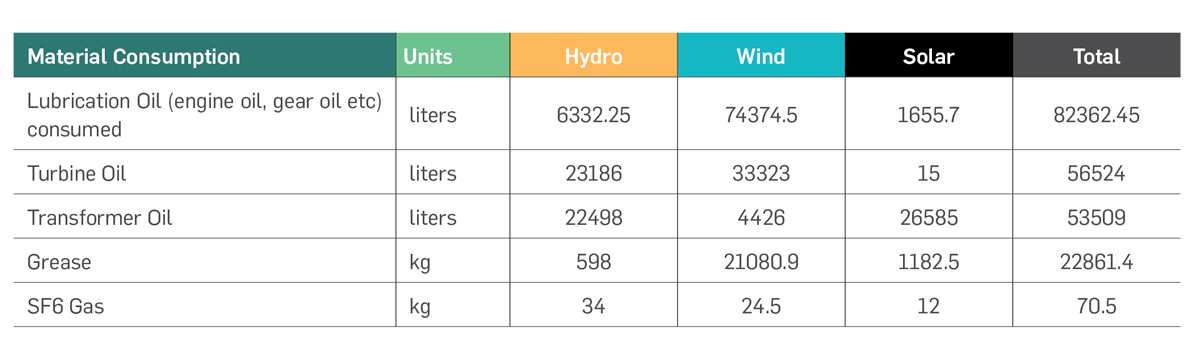

Material Consumption & Conservation

Wind, Solar, Hydro plants do not consume any input fuel for power generation. Thus, the fuel consumed in these plants are

primarily used for O&M purposes. The material consumption during the reporting year for the above is presented below

Greenko has instituted a Material conservation

program that aims to reduce the consumption

of raw materials, consumables, packaging

materials and also strives to increase the use

of recycled or bio-degradable materials. At

all the GAM plants, Greenko recycles scrap

refuse, consumables, and packing material as

a part of its material conservation program.

Following are some of the initiatives taken up:

- Short unproductive DC cables are

removed and reused in other areas

which resulted in an 8% reduction in the

requirement of new cables.

- Optimum use of Packing Material

by manufacturers/ suppliers, other

protection materials significantly

resulted in a 12% reduction in packing

material in the year 2020.

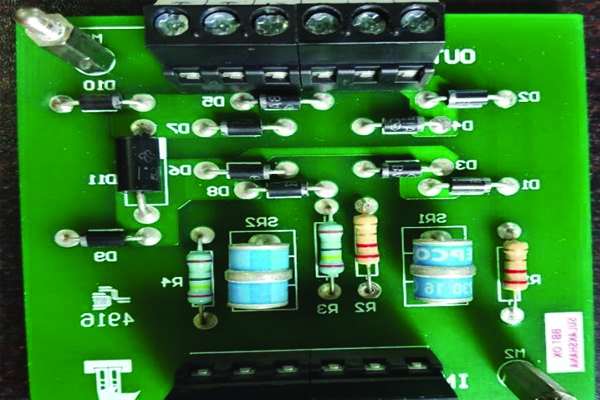

- At Zuvan Solar site the Electronic PCBs were repaired and reused for SPDs of SCBs and Inverter Cooling Fans.

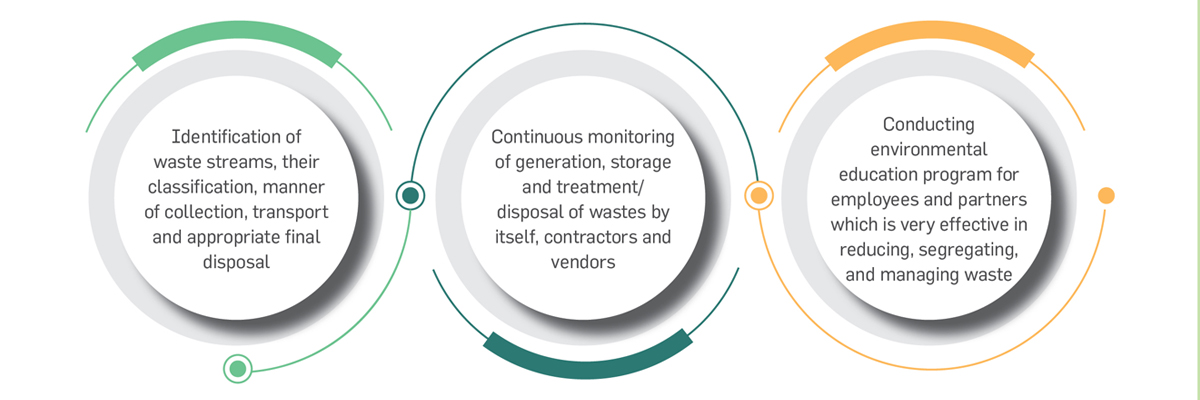

Waste Management

Greenko believes that circular economic practices will be the key element for driving sustainable development The Company’s

waste management practices adhere to the principles of Environmental and Social Management System which requires

conformance to legal requirements along with the reduction in waste generation through reuse or recycle, whenever possible.

The ESMS mandates to identify the waste streams within the organization and continuously monitors waste generation. Further,

ESMS also recommends creating awareness among key stakeholders to develop the circular economic culture. Greenko has

also initiated Plastic Protocol in this reporting year to delineate the usage of single-use plastics in operation and is exploring the

feasibility of replacing them with a sustainable alternative.

Waste Management practices at Greenko

Greenko conducts internal audits to quantify waste generation and to explore the potentials for incorporating the best waste

management practices. At operational sites of Greenko, this management program is carried out with the help of an authorized

third party, which involves monitoring garbage collection, segregation, and disposal of all the waste generated at the operating

premises. Segregated recyclable wastes are sold to authorized recyclers. A part of wastes requiring treatment before disposal

is sent to hazardous waste treatment facilities and others are used in landfills.

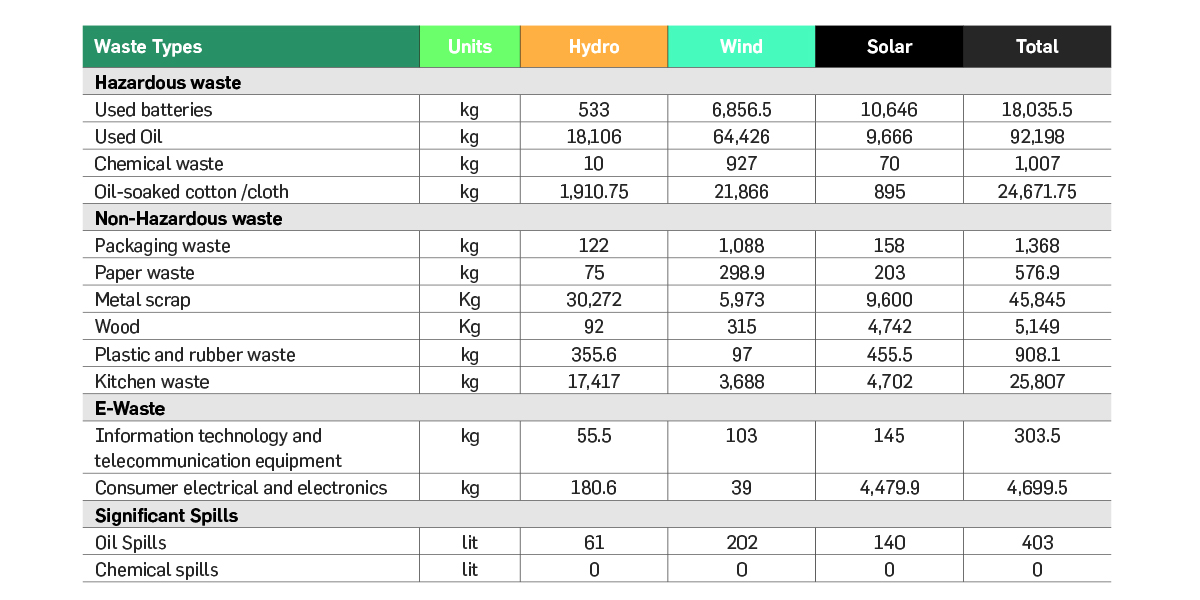

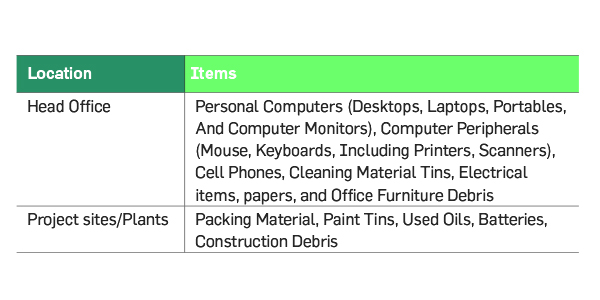

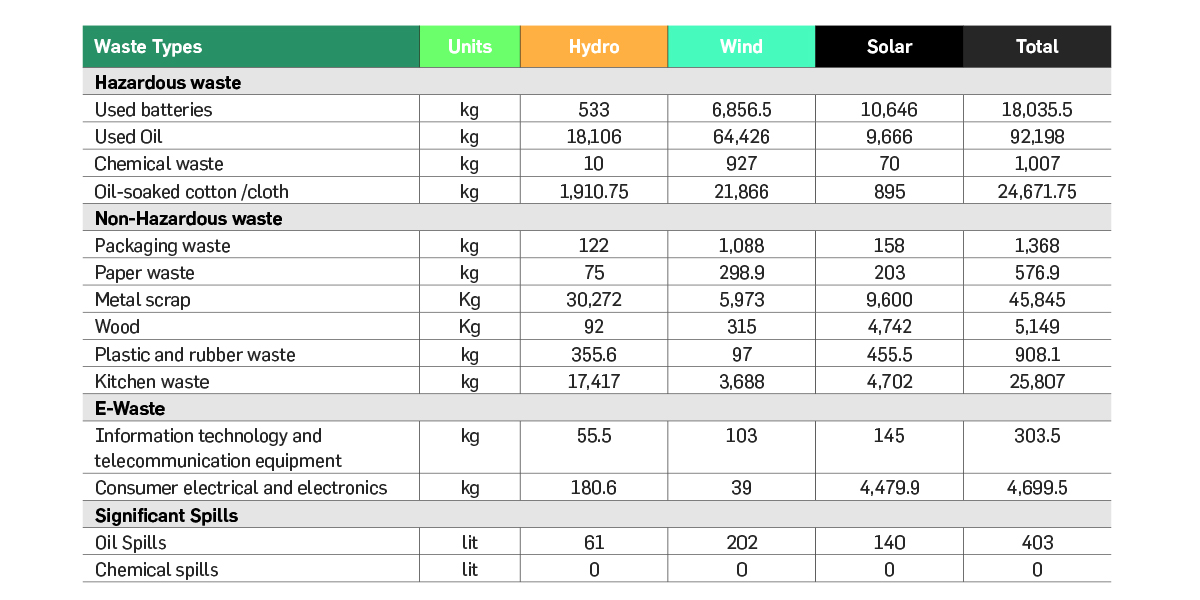

Waste Generation by type

E-Waste Management

Greenko’s approach for waste management

includes Reduce-Reuse-Recycle-Reclaim-

Disposal to minimize its environmental

footprint. The Group stringently follows

E-Waste Management rules to treat and

reuse E-Waste resulting from technological

upgradations, capacity augmentation, and

other business processes. All these wastes

are collected by the ICT department which

is then segregated and recycled. All the nonreusable

hazardous e-waste, including lead

batteries, are disposed through authorised

recyclers approved by Central and State

Pollution Control Boards. In FY 2020-21,

the total E-Waste generated by operations

was estimated to be 4699.5 kgs. Greenko

also donates the unused computers and

other peripheral devices to various schools,

orphanages, NGOs, etc.

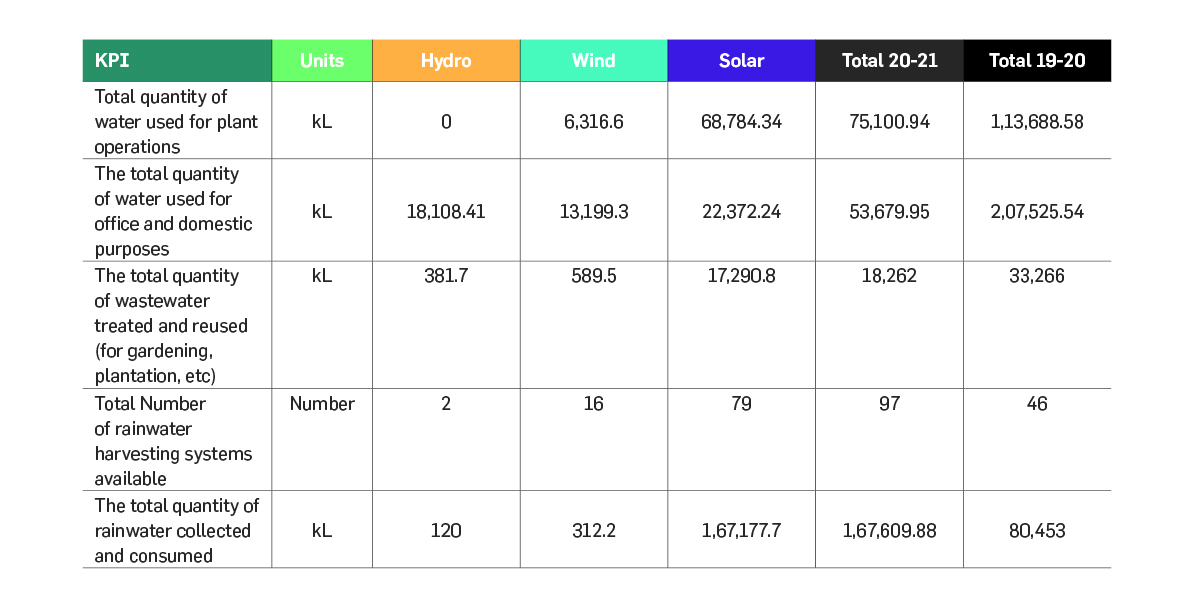

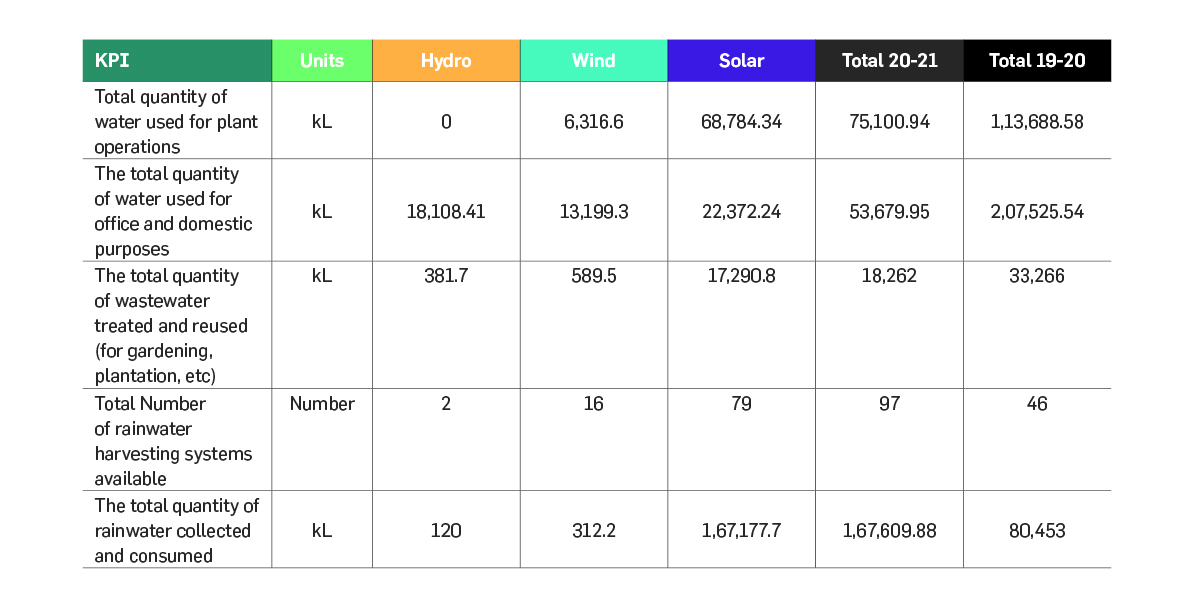

Water Management

Greenko’s operations are less water-intensive

and hence, water is mainly used for cleaning

of solar modules, domestic requirements,

construction, and biodiversity preservation

of the surrounding ecosystem. Greenko

continues to understand, monitor, and

record its freshwater usage, domestic water

consumption, operational water consumption

and wastewater discharge. Greenko closely

evaluates water use efficiency as one of the

criteria for exploring the feasibility of new

technologies and projects.

The impacts caused by its operations on

water bodies are carefully analysed by

Greenko and significant investments are

made to reinforce measures to limit such

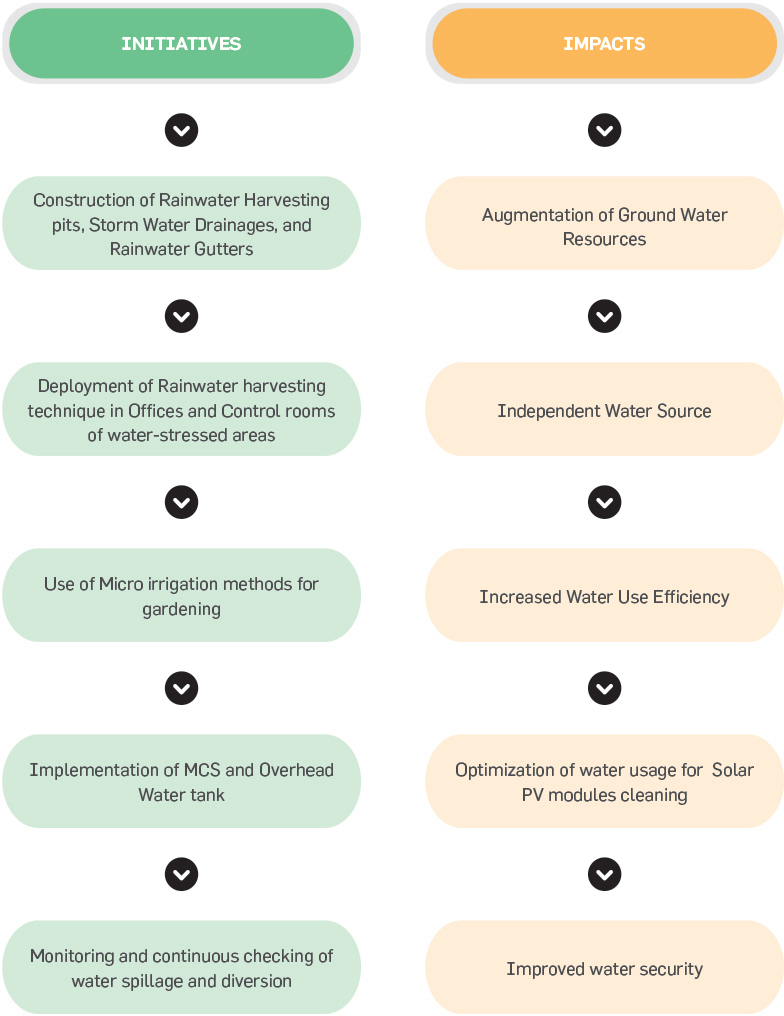

effects. The main components of these initiatives are development of watersheds, rainwater harvesting, drip or

sprinkler irrigation and water-efficient cleaning technologies. The Group has

built various natural drainage structures, water recharge systems, and storage

facilities in and around its operational areas through which Greenko attempts

to harnesses rainfall. Through this, Greenko systematizes water requirements

of the surrounding community and operations. Through continuous efforts of

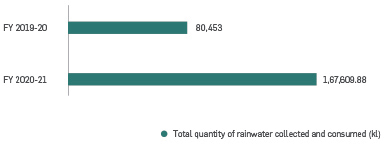

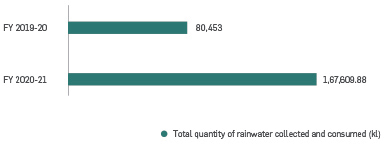

Greenko, the number of rainwater harvesting structures are nearly doubled and

the total quantity of rainwater harvested stands at 167609 kL.

Progressive in Water management practices at Greenko

Water Management

Water Management Practices and its Impacts

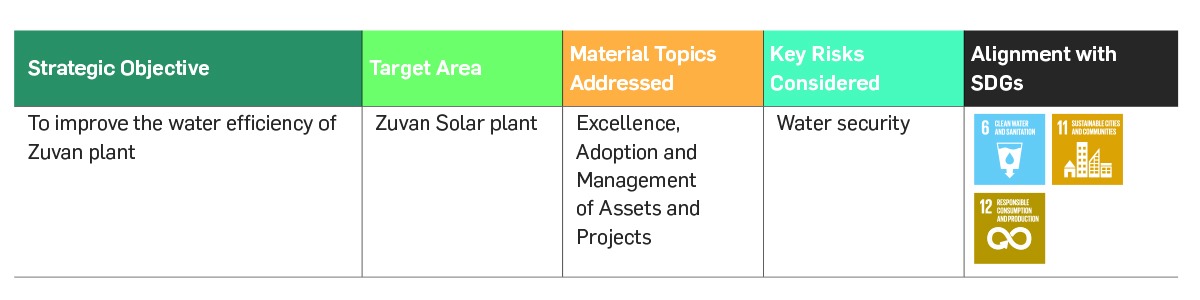

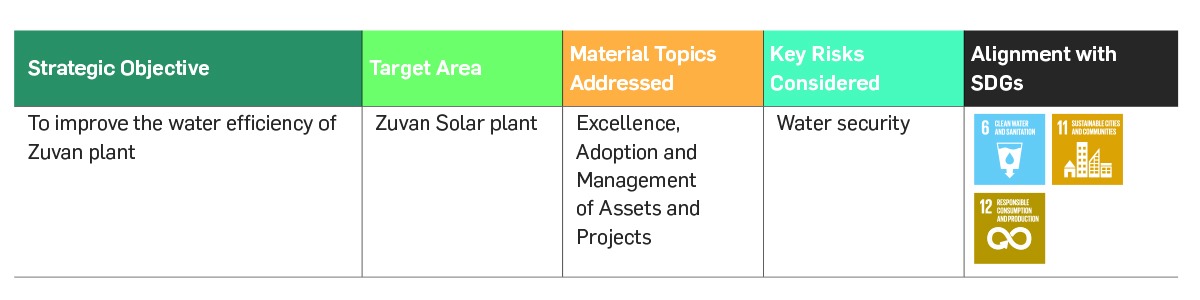

Value Creation Story: Water Conservation at Zuvan Solar Plant

Location: Zuvan Solar plant

Summary

The main water sources of Zuvan plant are

a reservoir, bore well, and a pond. Reservoir

water is used for module cleaning and

conventional earth pit maintenance. Borewell

water is used for domestic consumption

and pond water is used for plantation,

gardening, and fire tenders. The plant is

reusing the module cleaning water for the

plantation of Aloe vera and Green grass

beneath the modules. This has also helped

in enhancing the module efficiency. Owing to

these conservation activities, the freshwater

consumption of plants reduced by 15% in the

current reporting year. In addition, various

pond restoration activities like dredging have

enhanced the rainwater potential of the pond.

The plant will continue its efforts and also set

a target for reducing freshwater consumption

further to 25% by the year 2022.

Key Achievements:

- Reduction in freshwater consumption by 15%

- An increase in rainwater storage potential of the pond

Energy Efficiency

Greenko is committed to adopting various

energy-efficient measures in its operations

to minimize the losses in generation,

transmission, and distribution and thereby

aspires to reduce its carbon footprint. Greenko

has implemented a multitude of energyefficient

measures in its operating locations,

some of which are enlisted below:

- Procurement of Energy Efficient Equipment in line with Bureau of Energy Efficiency (BEE) Guidelines

- Replacement of conventional Lights with CFL & LED lights

- Regular maintenance of auxiliary equipment

- Operational management of hydro plants- arresting water leakage through proper grouting work in powerhouses

- Installing Light Arresters in between 33 kV line to reduce the breakdown time

- NRV Modification for pitch cylinder for reducing oil leakages in HUB (WTG)

- Installed Grease collectors which are used for waste or Excess grease collection from wind turbine blades to reduce breakdown time

- To capture real-time

data in-house application

has been developed by

Greenko. With the help

of this app ‘CELESTE’

Inverter operations

are being monitored

thereby improving power

generation

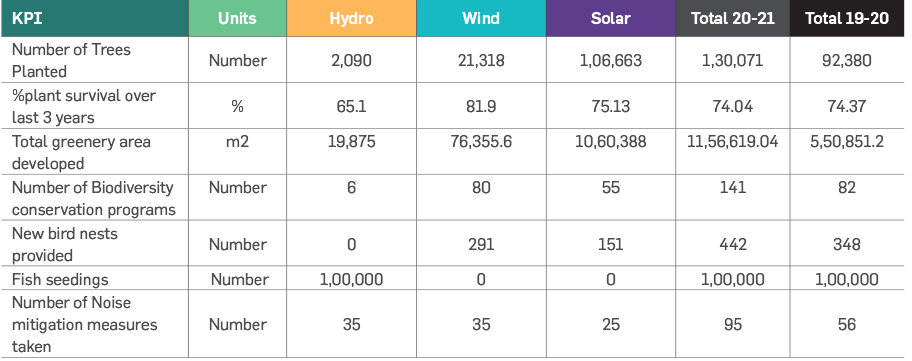

Ecological Restoration

Biodiversity

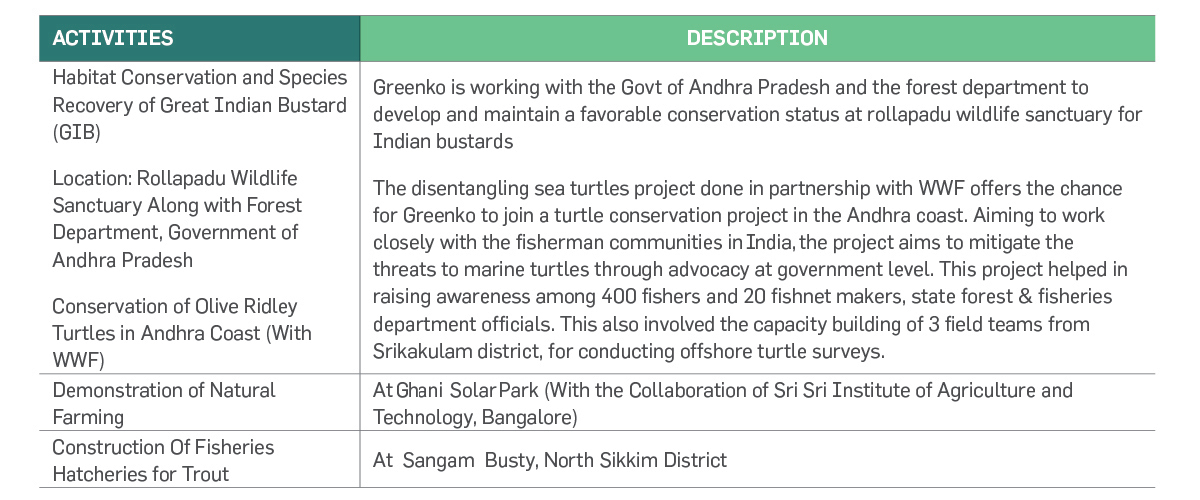

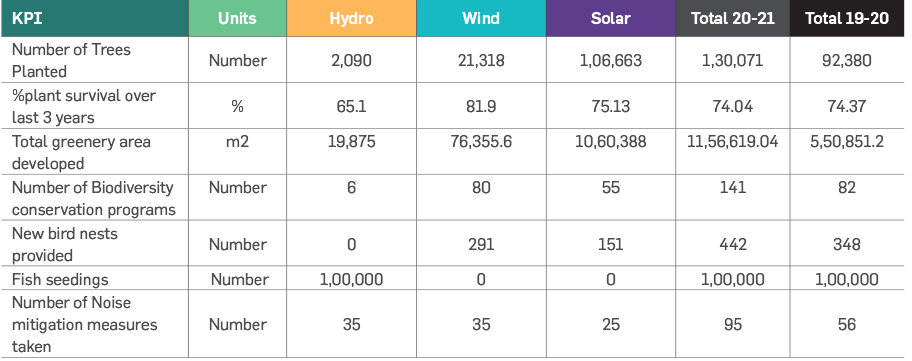

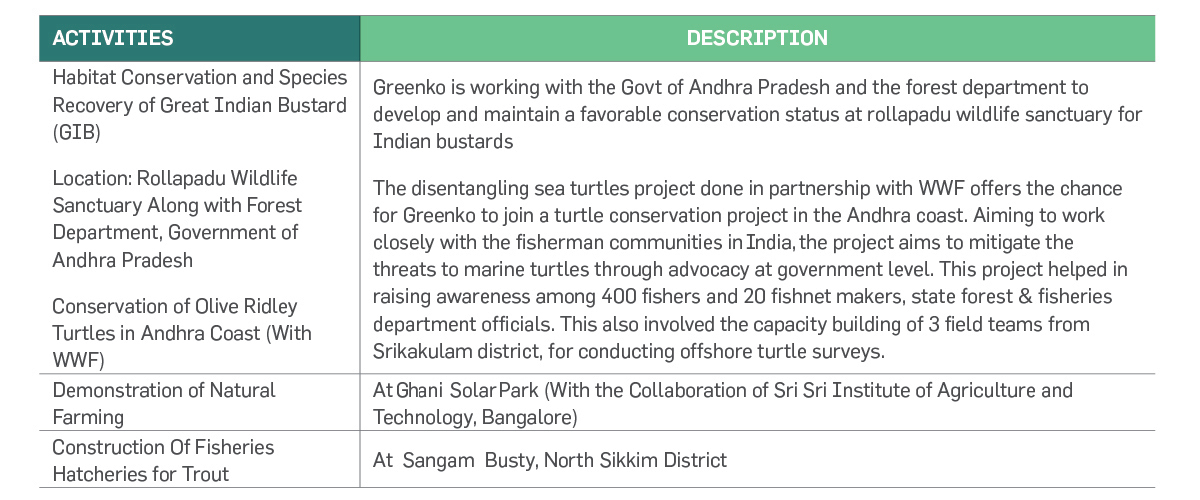

Greenko’s Projects are designed, developed, and operated based on extensive Environmental Impact Assessment (EIA) carried

out during the planning stage. The company makes tremendous efforts to avoid setting up its operations in biological hotspots

and protected areas. Further Greenko proactively implements projects like habitat conservation, natural or sustainable farming,

protecting sea-based wildlife systems, fish seeding initiatives to restore, protect, and enhance biodiversity. Greenko has also

undertaken extensive plantation programs at all its operational sites to develop natural CO2 sinks.

Biodiversity Management

In addition, the Group is also supporting various Biodiversity Conservation activities and Natural resource management

programs in various geographical locations. To conserve and mitigate biodiversity loss, Greenko diligently conserves one

endangered species, each year, in the regions of its operations. During the last few years, the Group has contributed towards the

conservation of Olive Ridley Turtles, Great Indian Bustard & Red Panda.

Initiatives on Biodiversity Conservation and their Impacts

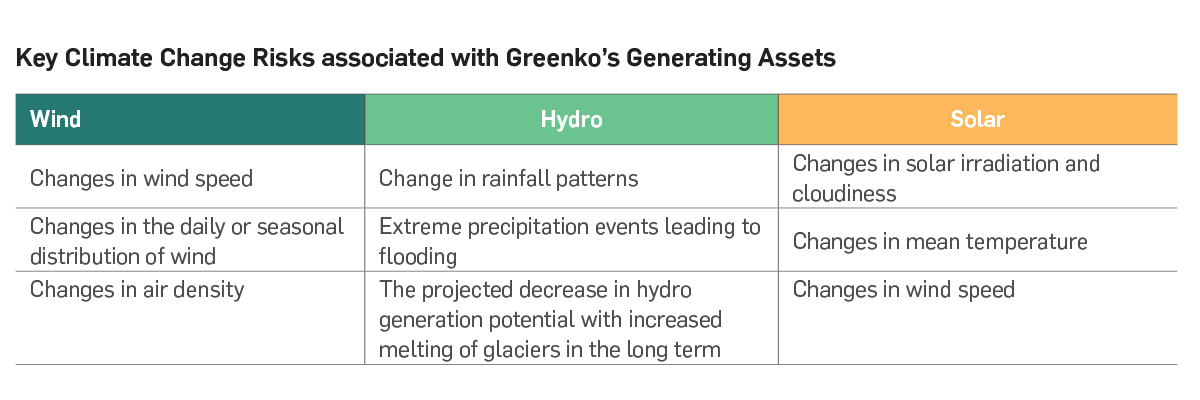

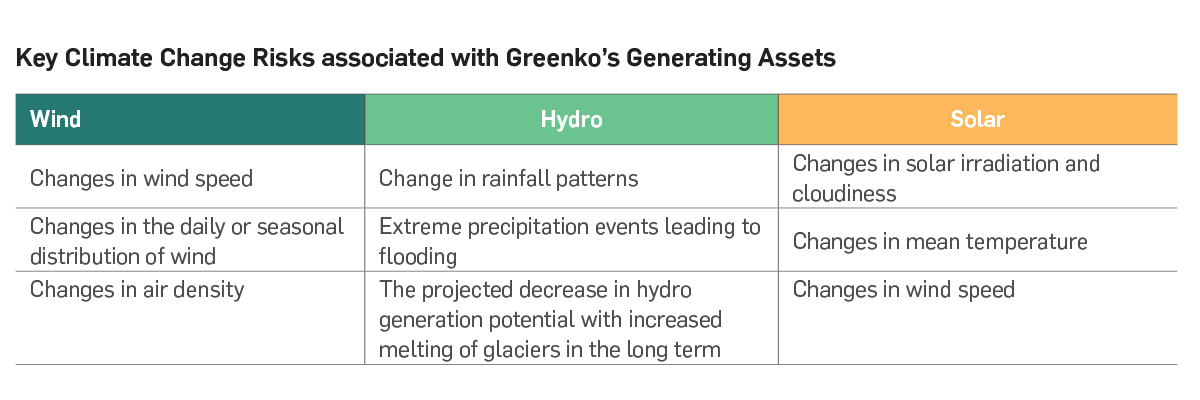

Climate Proofing the Business

Climate Risk Assessment and Management at Greenko

Greenko is aligning its business

models and asset management

practices to cope with the extreme

weather events resulting from

dynamic climate conditions.The

climate risk assessment is conducted

as a part of project management

to identify, analyze and mitigate

potential physical and transitional

climate risks. This analysis is

proactively and systematically

performed based on climate change

related events, trends, forecasts, and

projections.

Physical Risks

In this context, Greenko has assessed

the impact of physical risks across

different stages of its operating

lifecycle, such as,

- Physical impact on renewable resource potential

- Physical impact on generating assets

- Physical impact on Transmission and Distribution infrastructure

Transitional Risks

This category of risks mainly

corresponds to future policy changes

to aid renewable energy transition

Greenko has conducted climate

risk assessment for six of its critical

operating sites to assess and manage

climate risk vulnerability of assets

and their productivity. The six sites

are as follows,

- Ghani solar, Kurnool, Andhra Pradesh

- SEI Adhavan, Tamil Nadu (Solar)

- Sneha Kinetic (Dikchu Hydropower project), Sikkim

- AMR Power, Karnataka (Hydro)

- Rayala Wind, Andhra Pradesh

- Tanot wind, Rajasthan

Greenko has studied and projected climate change impacts on its operations using IPCC’s RCP 4.5 scenario which

is the low-medium emission pathway (equivalent to 1.7-3.2°C temperature increase). The climate change projections

were studied for the period of 2020-2039 (Short term) and 2040- 2059 (Medium Term). The assessment revealed that

transitional risks are well-identified and addressed by Greenko. Physical risks like heat stress may possess certain threats

to operations and various water conservation and harvesting strategies are planned to mitigate those risks. The physical

impacts on resource availability viz., wind pattern, solar radiation, and hydrological flows are to be addressed through

agility, predictive and adaptive capabilities developed through Digitalization. The additional system and infrastructural

requirements to develop climate-resilient assets were also evaluated and planned accordingly.

Greenko Commits to Climate Pledge

The Climate Pledge co-founded by Amazon with Global Optimism in 2019

Net Zero Carbon by 2040

Part of UNFCCC “Race To Zero” and part of the solution - 10 years Early

- Community of

companies and

organizations,

working

together to

crack the

climate crisis

and solve the

challenges of

decarbonizing

our economy.

- Greenko Has

joined 114

businesses

across the

globe and

accepted the

challenge

of Climate

Pledge.

The Climate Pledge Requires the signatories to:

Extending Life and Managing End of Life

Lifecycle Management at Greenko

An LCA study is conducted for analyzing the

environmental impact of a product/system

across the various stages of its lifecycle. In this

case, the goal of the LCA study is to analyze

the environmental impacts associated with

the production of electricity from Greenko’s

different renewable energy technologies i.e.,

onshore wind plant (600MW), solar plant

(3000MW), and a pumped storage hydro plant

(1200MW) in line with ISO 14040 and 14044

standards and explore the feasibility and

consequences of the extension of life and end

of life management. A process-based LCA

approach was utilized for this study.

A cradle-grave LCA study was conducted i.e.,

the environmental impacts are calculated

over the entire lifecycle of the renewable

energy technology plants involving the

extraction of raw materials, manufacturing

of the components, assembling, transport,

operation, maintenance, and end-oflife

treatment. Through this study, it

was understood that the production and

disposal stages contribute to the maximum

environmental impacts of the onshore wind,

solar, and pumped storage hydro plants.

Although variables such as the production

of raw materials and components used in

the plants are not directly under Greenko’s

control, significant measures will be taken by

Greenko to ensure the proper recycling and

reuse of raw materials used in the various

components of renewable energy plants,

ensuring that the raw materials are not

ending up in landfills.

Environmental stewardship

Greenko adopts the concept of Environmental

stewardship which means ‘Being

responsible for all phases of the project

life cycle’. Through its strategic governance,

the Group has taken steps to minimize the environmental ramifications by committing

to various principles like Extended Producer

Responsibility (EPR), Design for Environment

(DfE), Reduce usage of toxic substances,

Impact assessment.

The Group carries out life cycle assessment

during the initial stages of every project

to minimize the environmental impacts

throughout the lifecycle of assets,

starting from design and development to

manufacturing, distribution, use, and disposal.

Greenko is also inspiring its suppliers to adopt

green practices thereby, culminating the

sustainability principles in its supply chain.

Life Cycle considerations are communicated

to the vendors through contractual obligations

and strict compliance is ensured. Several

Audit mechanisms are instituted by Greenko

to evaluate the environmental performance of Suppliers/vendors with

respect to Emissions,

Materials, Water, Chemicals,

etc.

Greenko is working with its

supply chain partners on

saving diesel by changing

the packing configuration,

changing the port etc. of

every order.

The Group also works for

a better End-of-life (EOL)

Management for the belowmentioned

products but, is

not limited to engaging the

certified Waste Carriers,

Hazardous Waste Disposal

License and Waste Operator

Licensees, etc.

Items covered under Environmental stewardship programs for EOL management

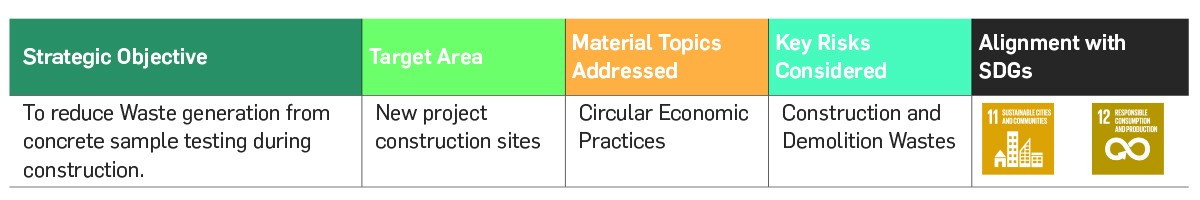

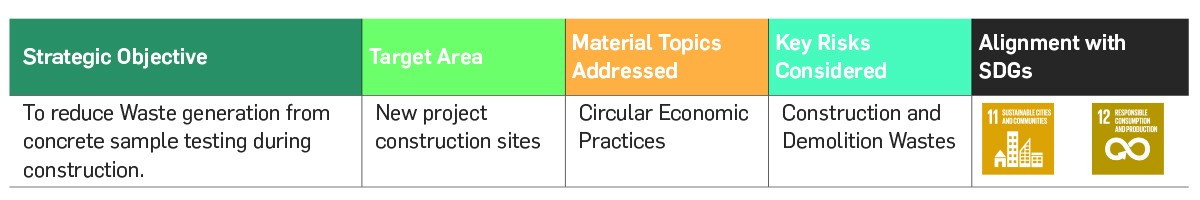

Value Creation Story: Recycle and Reuse of Crushed Concrete Cube wastes

Location: Himachal Pradesh, Andhra Pradesh, Madhya Pradesh, Telangana

Partners Involved: Jeori projects, Ghani Solar Project, Jilesh Power

Summary

Along with its partners, Greenko initiated

various projects to utilize the waste

concrete cubes generated from concrete

testing samples. The cubes are used as

alternatives for bricks in constructing various

structures like Walls, Pedestals, Steps, Water

tanks, Earth pit chambers, Poles. Greenko

will continue to give a second life to these

concrete cubes and continues to divert them

from landfills.

Benefits Achieved

- Diversion of Construction wastes from Landfills

- Reduction in Construction cost of new structures

Innovative Approach of the Project

Greenko has extended the life of concrete

cubes which would otherwise be sent to

landfills. These concrete cubes are stronger

than brick and hence, there is no additional

requirement for rendering works which result

in cost saving.

Value Created

The crushed cubes are used for construction of the following non-structural elements:

I. Construction of the following at plant areas and villages:

- Pedestal for containers and restroom walls, RO plants, etc.

- Construction of walls for water tank in the project area

- Kerb walls for roads

II. Base for cleaning area and ground clearance for storage material, drainage works.

III. Recycled aggregate/ crushed concrete cube used for pavement subgrade.

IV. To make cage wall for plants and trees

Construction of Surface Water Storage tank with concrete cubes, Madhya Pradesh

(GRI 306-2)

(GRI 305-1, 305-2, 305-3), (GRI 305-5)

(GRI 305-7), (GRI 301-1, 301-2)

(GRI 306-3), (GRI 306-4), (GRI 306-5)

(GRI 303-5)

(GRI 304-1, 304-2, 304-3, 304-4)

GRI (308-1, 308-2)

Greenko’s business

directly contributes to

UNSDG 13-Climate Action

and UNSDG 7-Affordable

and Clean Energy and

UNSDG 12-Responsible

Consumption and

Production goals.

Greenko’s business

directly contributes to

UNSDG 13-Climate Action

and UNSDG 7-Affordable

and Clean Energy and

UNSDG 12-Responsible

Consumption and

Production goals.