Message from COO-Projects

Dear Stakeholders,

The world economies are transforming towards

new, low-emission pathways and India is well

positioned to play a leading role in this process

globally. Also, through its Intended Nationally

Determined Contributions (INDCs), India has

pledged to reduce its emissions significantly

(Paris Agreement).

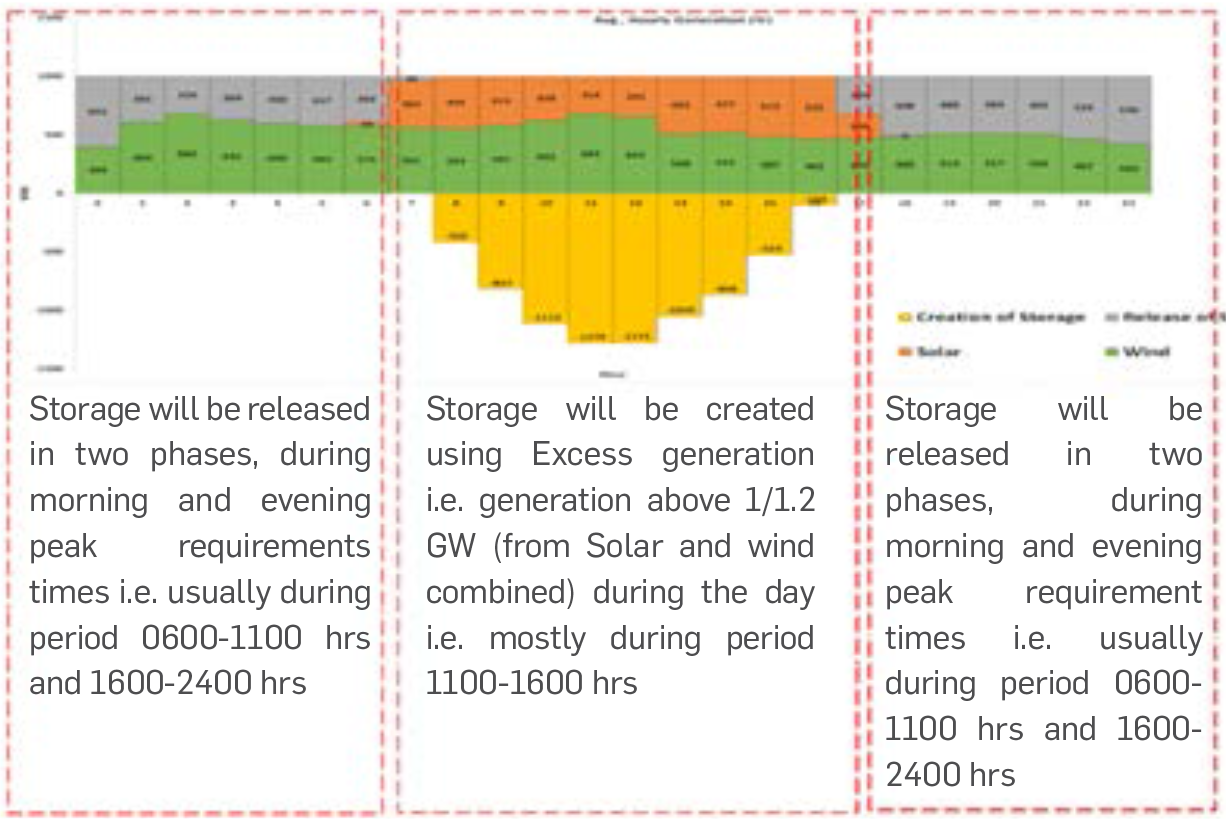

To meet the global ambition of Net-Zero 2050,

firm, schedulable, dispatchable renewable

power is essential for deep decarbonization.

Long-duration, Stand-Alone, Off-Stream,

Closed Loop Pumped Storage and Intelligent

Energy Platform is the best solutions for the

same.

Wind and Solar, are the lowest-cost sources

of new energy, however, their inherent infirm

and non-schedulable nature presents a huge

challenge for integrating large RE capacities,

while maintaining the grid stability. To

overcome this challenge, we have devised

unique pumped storage (PSP) platform that

enables lowest cost dispatchable RE power.

The Integrated Renewable Energy Storage

Project (IRESP) will harness the cost-effective

variable power of solar and wind resources

with digitally connected storage infrastructure

to provide scheduled and flexible power to

the grid. Our IRESPs are designed to provide

the necessary scale (large volume of energy

storage) and have a long-life cycle resulting

in the lowest cost of delivered (Schedulable

Power On-Demand) SPOD energy over the life

of the projects. Our agile workforce has come

up with unconventional ideas for an intelligent

in-house solution for integrating infirm and

non-schedulable renewable energy and to

meet schedulable power demand.

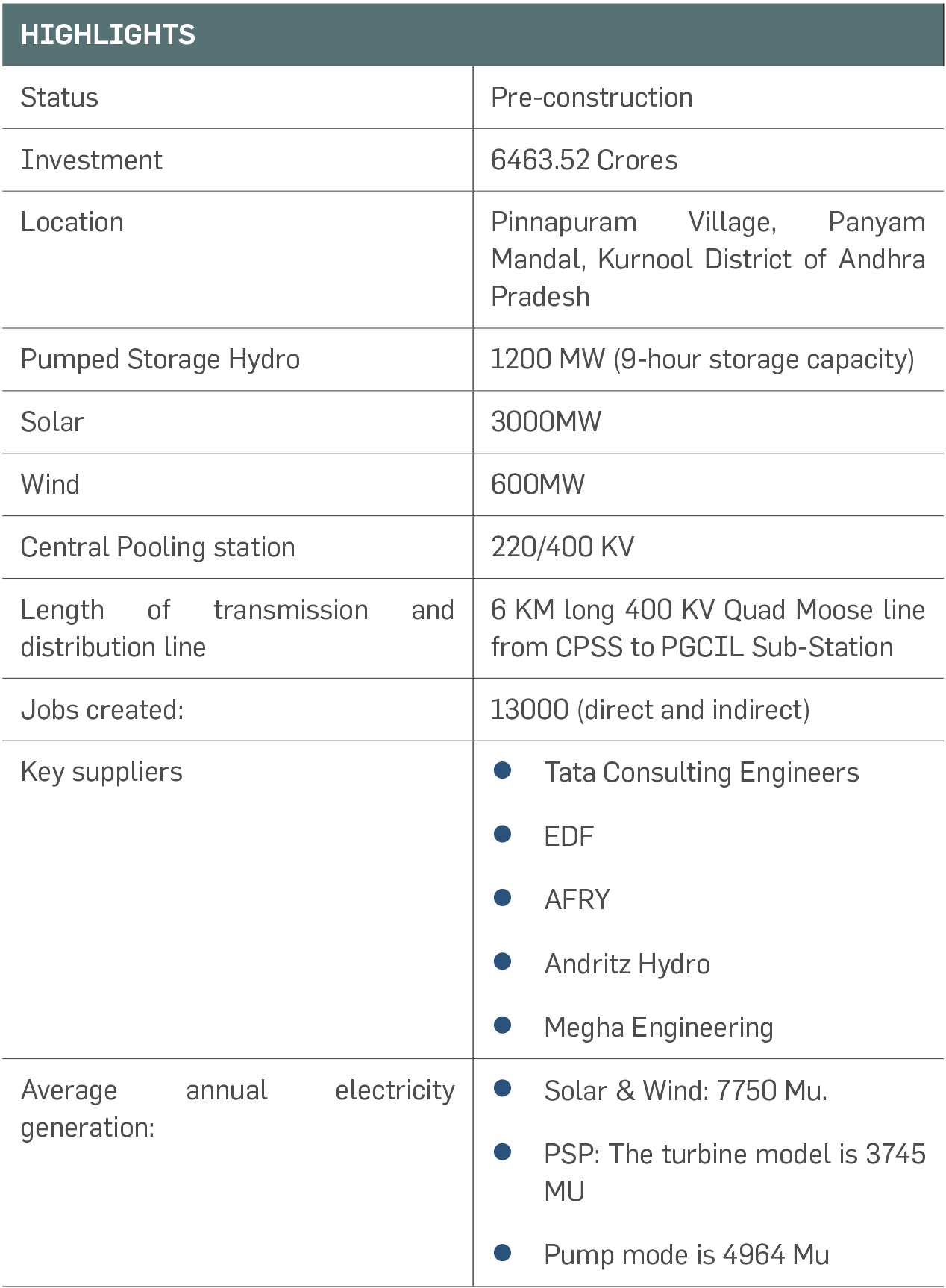

The Pinnapuram Integrated Renewable

Energy Storage Project (IRESP), the first

one to begin execution amongst many

such projects in the pipeline, is the World’s

First & Largest Gigawatt Scale integrated

project with solar, wind, and pumped storage

components. The IRESP Project can meet the

dynamic needs of DISCOMs/STUs viz., Round

The Clock (RTC) Base Load Energy, 18 Hours

Base Load Energy as per Demand or 12 Hour

Peak Load Energy as per demand. Further,

novel features of our IRESP design are:

- Optimal capacity utilization of the renewable energy components of the IRESP viz., Solar & Wind.

- Operational flexibility, faster active and reactive power adjustment, quick reaction time& higher efficiencies to meet the grid requirements.

- Fixed Speed synchronous machines

- Closed loop and off-stream design.

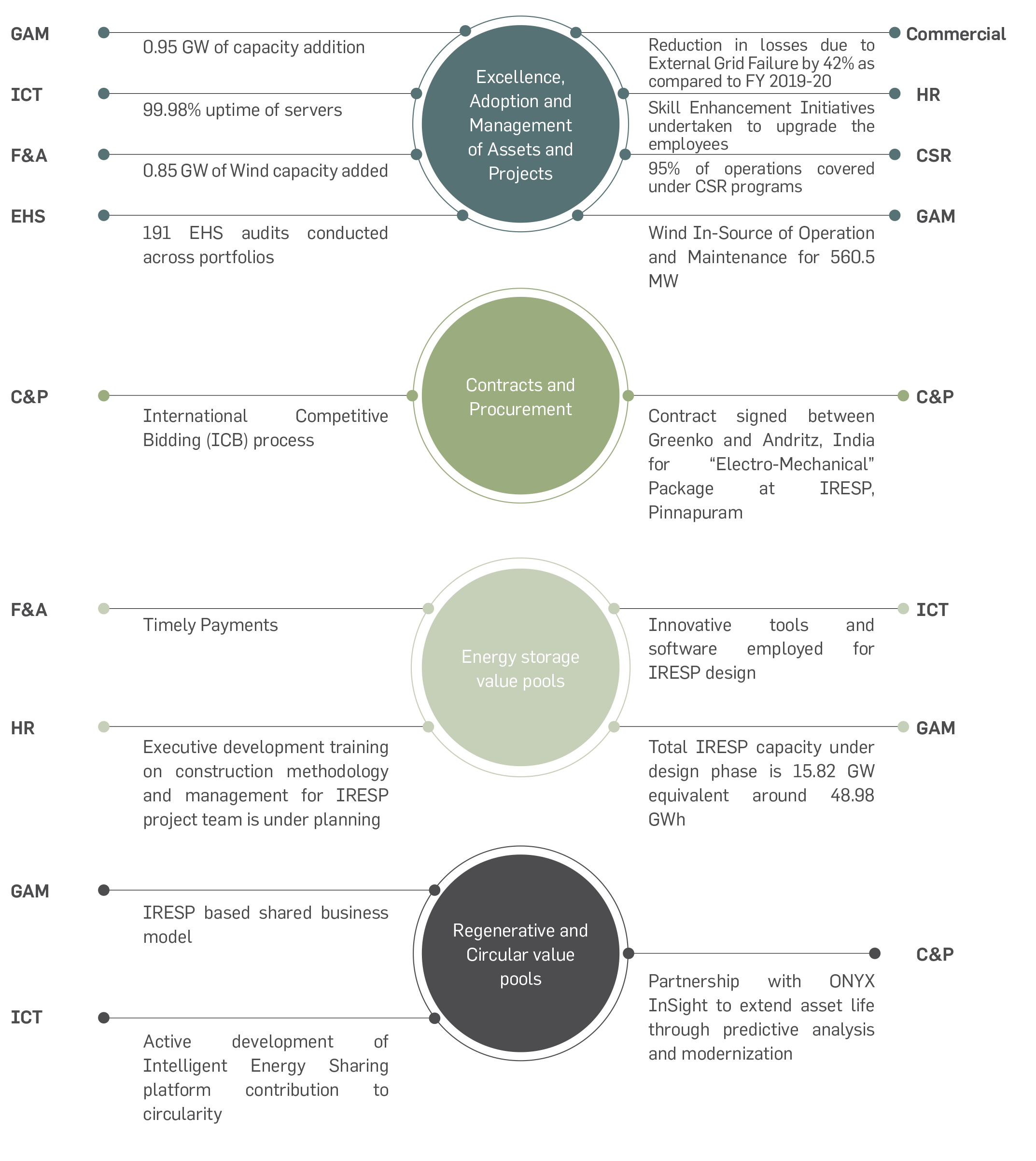

We have upskilled and reskilled our

workforce in collaboration with qualified

and experienced NICMAR faculty on all the

aspects of IRESP viz. quality, safety, and

construction project management. Further,

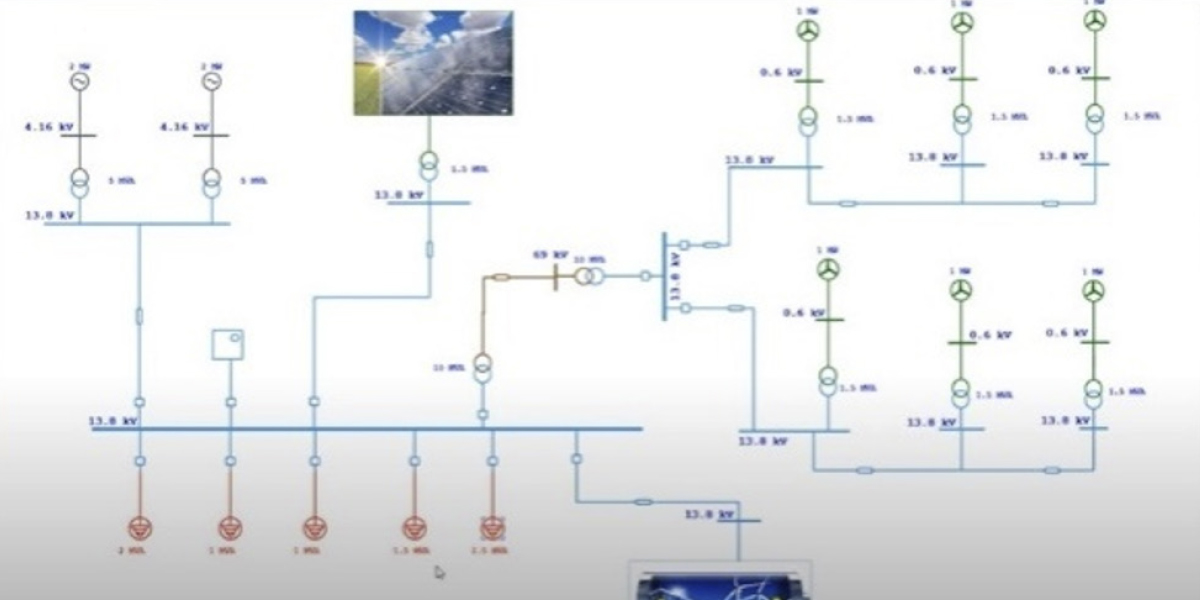

Greenko Load Dispatch Center (GLDC) will be

equipped with Energy Management System

along with Auto Generation Control (AGC)

& Intelligent Demand Supply Management

System (IDSMS) designed to monitor and

control solar, wind and hydro generations in

the system to match the load requirement.

The Forecasting and Scheduling modules

supported by Artificial Intelligence(AI) and

machine language(ML) will compare the

data received from forecasting & scheduling

and real time data from generating plants,

and will generate schedule for PSP. The

redundant controllers at PSP receives the

schedule generated from GLDC to ensure

continuous supply of contracted power to the

designated point of common coupling (PCC)

at power evacuation grid substation.

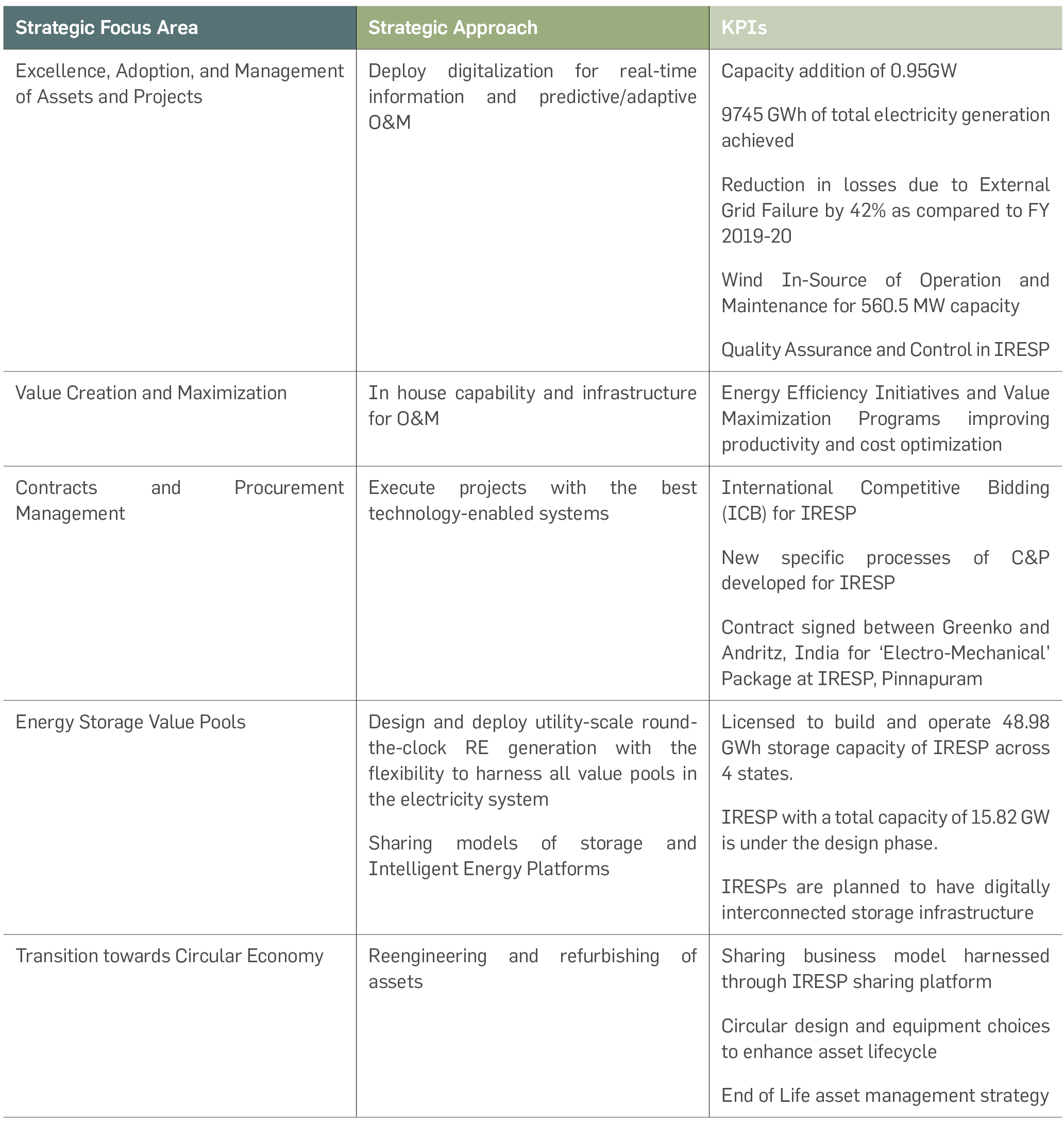

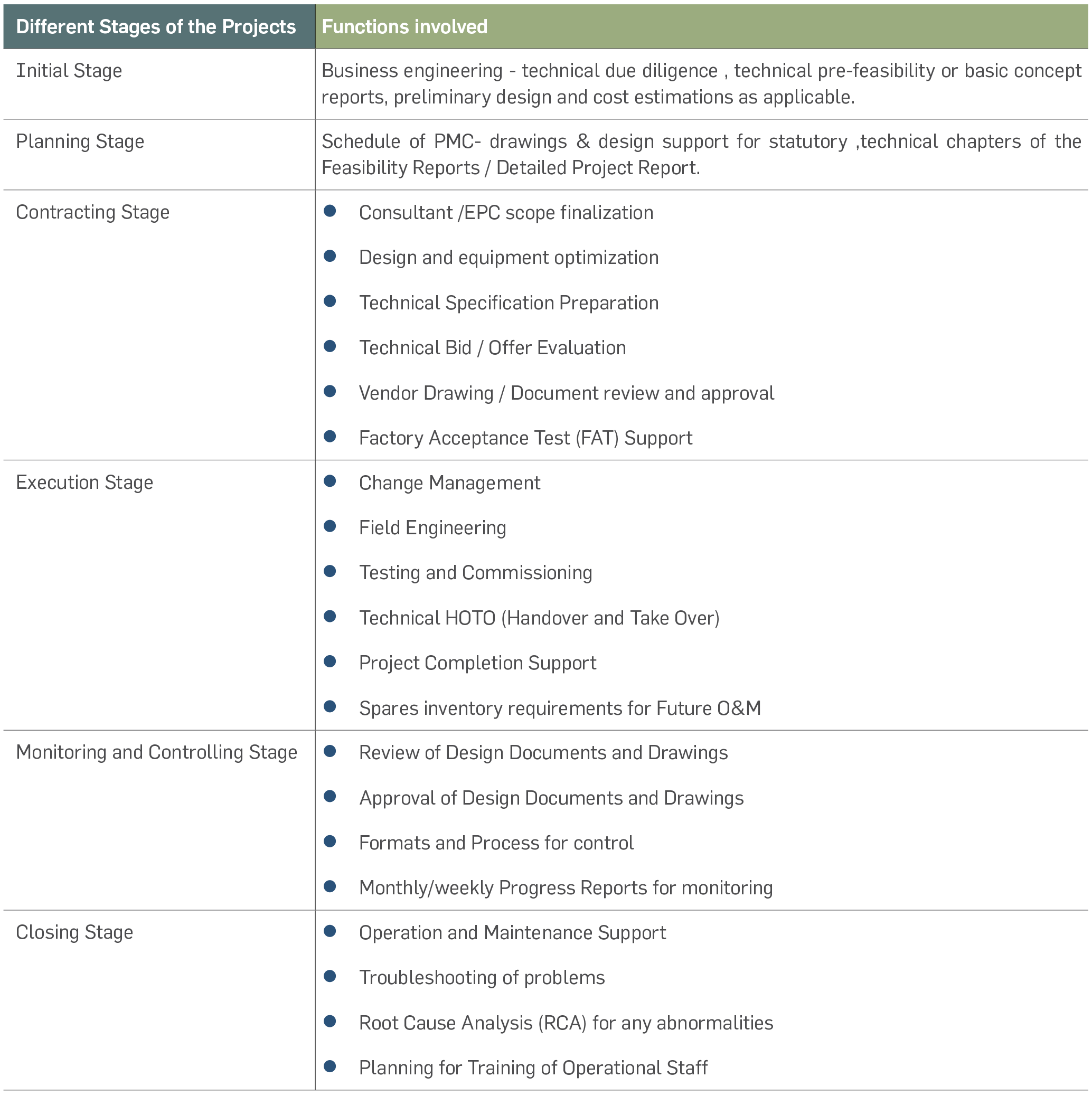

We have robust inhouse engineering team in

Civil, E & M and Transmission wings who have

done all the preliminary engineering required

for DPR and all initial works including land

requirement, site selection and sizing of all

major components. In addition to execute this

IRESP, we are working with very experienced

global consulting companies such as, AFRY

for the detailed design of all the civil works and

Tata consulting Engineer, and EDF for review

of both Civil E & M and Transmission designs.

To spot and partner with the best global

resources and expertise, we have followed

International Competitive Bidding and

adhered to the guidelines of IFC. The inhouse

Contracts and Procurement (C & P) team has developed a system to take care of bids, right

from preparation of international competitive

bidding to finalisation of the contracts. The

systems and processes developed during

this procurement are now standardized for

deployment in upcoming projects. Further, our

project management teams have designed the

SOPs to address the challenges of balancing

flexibility and robustness. Our partnerships

with the vendors are executed in a twining

mode, to learn from each other and to make

the knowledge and skill transfer smoother

at the closure of the contract. Additionally,

Greenko has also tied up with Austria-based

international technology group Andritz for the

supply of Electro-Mechanical equipment for

the 1200 MW (6 Units) Pinnapuram pumped

storage plant in Andhra Pradesh.

The PMC team of Greenko takes care of

planning, monitoring and the supply chain

management of the project including plant

and machinery requirement of the project,

duly lassoing with the execution team. The

execution team prepares the work schedule

and coordinates with different work fronts

including the interface issues and ensures

smooth flow of work as per the schedule.

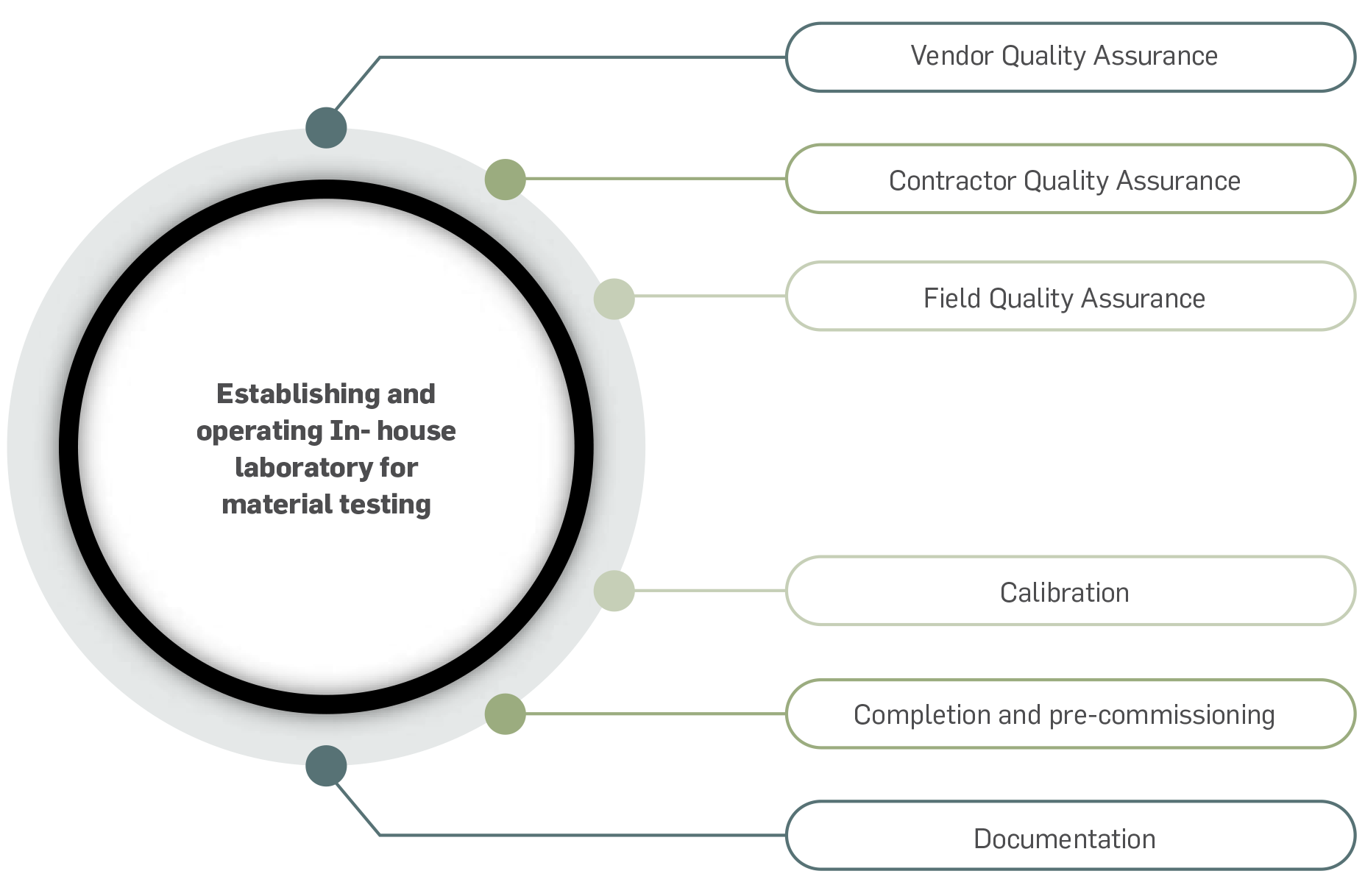

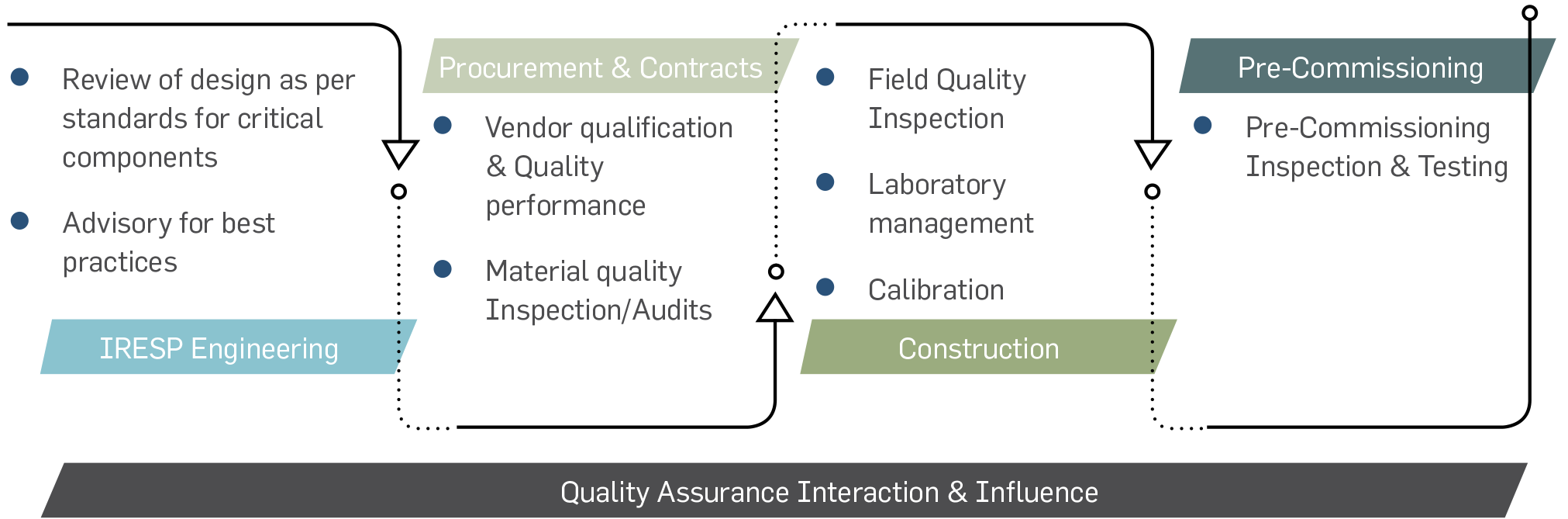

The QA/QC teams diligently established good

practices of quality standards in building and

operating energy assets while supporting

the Strategic Business Units to deliver their

business plans. The teams are proficient

in handling power sales, project financing,

construction, insurance, equipment,

and supply which makes a unique value

proposition. A monthly QA report on all critical

project activities is shared with Leadership

team. Going forward, we will decentralize

and digitalise our QS and QAQC processes

and establish Advanced Central Labs at each

cluster. As we move from GKO 3.0 to GKO 4.0,

digitalization will provide a unified platform

for on-site teams, project EPC and leadership

to have real-time data on project monitoring

and progress.

While the construction of our first pumped

storage at Pinnapuram is underway, we

have also developed significant expertise in

pumped hydro components and are working

towards the final product. Simultaneously, we have in our construction

pipeline 4 IRESP projects

and despite the delays that

have already happened in

regulatory processes, we

will strive hard to complete

these projects within the

time schedule. We realise

that our success in this

endeavor is contingent

upon active cooperation of

all stakeholders including

employees, suppliers,

regulators, public authorities,

and communities. A multistage

evaluation process

is conducted by the Board

during conceptualization of

new projects that includes

ESIA and ESMS. We call

upon our stakeholders

to actively engage with

us for a successful joint

endeavor to transform the

electric system in India and

contribute toward Global low

carbon growth.

As we look ahead towards

the execution of our first

IRESP project, we have

set ourselves on stringent

execution timeframes.

We have lost some time

in the regulatory process,

but we are hopeful to

complete the process within

the stipulated time. The

support and cooperation

of our stakeholders in this

commitment now is more

important than ever before,

together we can actively

engage and successfully

transform the electric

system in India

Adiseshu Gopalam

Chief Operating Officer-Projects