Addressing India’s commitment to deep decarbonization of the energy sector, Greenko operates responsibly, guaranteeing reliability, and permanence to build a fully sustainable energy system based on renewables. Greenko is highly proactive in identifying and responding to the challenges and diverse value pools emerging as a result of the rapidly changing energy landscape. To harness value pools and cope with challenges, Greenko is practicing an operating model that is characterized by excellence, agility, and resilience.

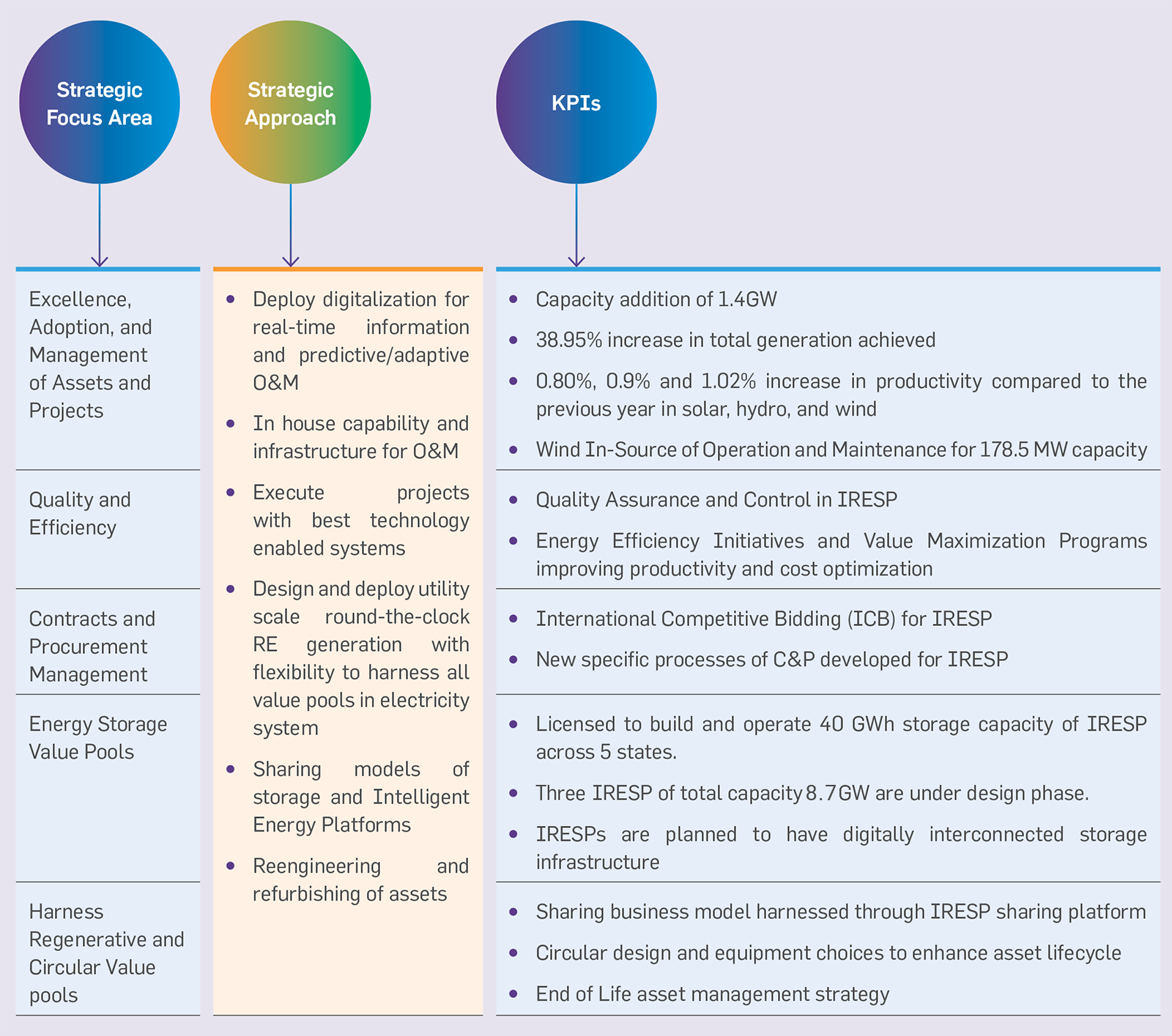

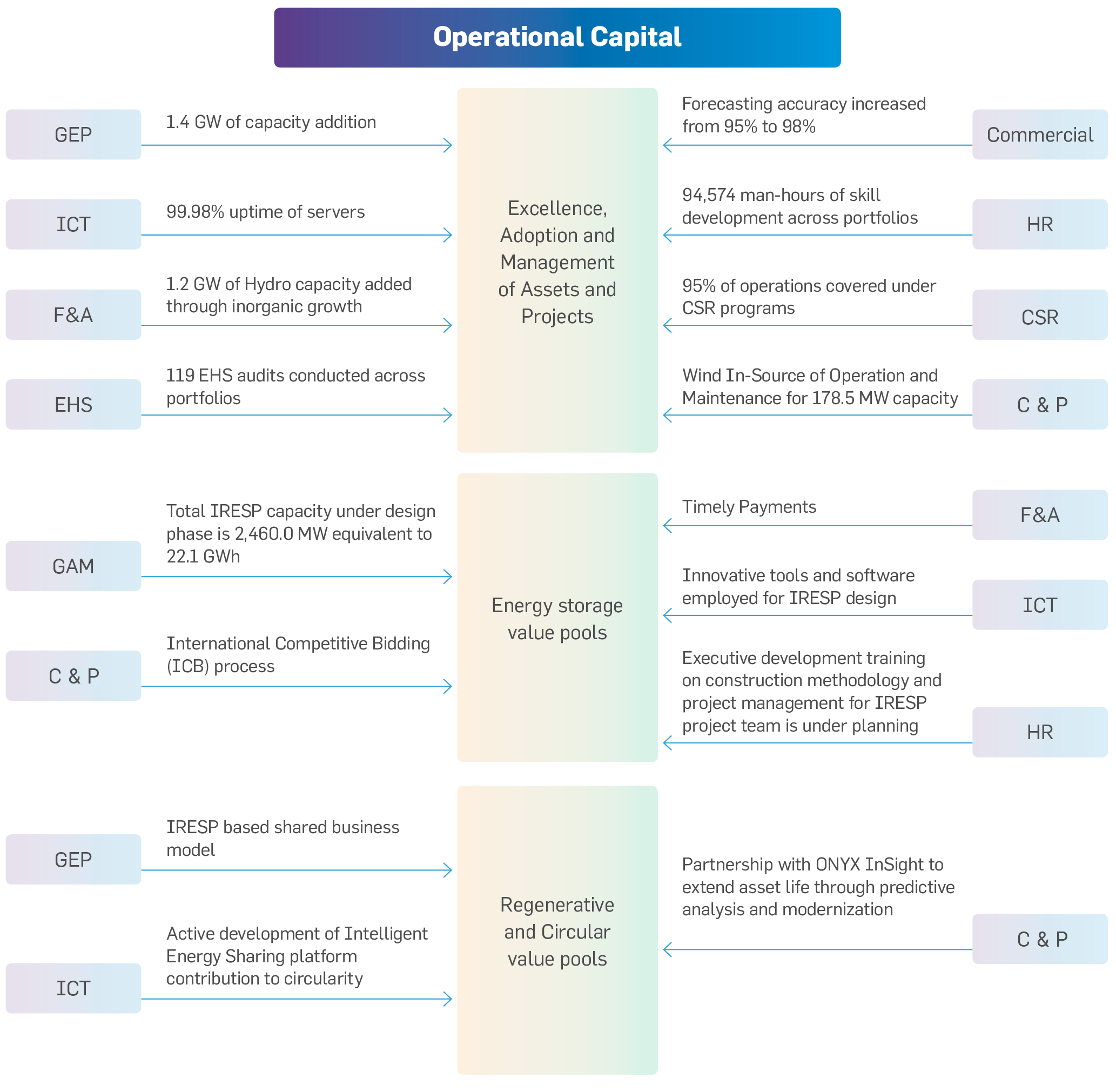

To preserve and enhance operational asset value and project management, Greenko has adopted the following effective strategic approaches viz., Excellence, Adoption and Management of Assets and Projects, Contract and Procurement Management, Quality, and Efficiency, Energy Storage Value Pools and Harness Regenerative and Circular Value Pools. The performance against each strategic approach is monitored, measured, and boosted year-on-year, using established key performance indicators. The review of performance on operational capital demonstrates Greenko’s preparedness for a smooth transition to GKO 4.0, to be able to generate 30 Billion Units of electricity by 2023

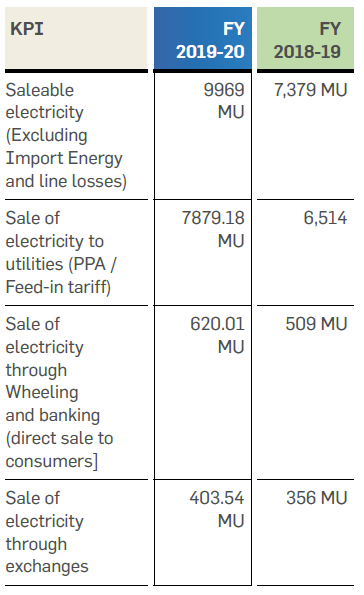

Strategic Direction: Ensure Sustainable Operations KPI

Greenko is in a unique position to address the country’s ambitious renewable capacity expansion programs, being a 100% renewable energy generator with a long-term vocation, aiming to build a fully sustainable energy system. Greenko is working continuously on adopting digitalizing and decentralizing energy solutions to achieve its goal of accelerating Decarbonization and harnessing newly emerging value pools. The organization’s extensive experience and expertise in renewable energy and digital technologies enable them to do so. In the current reporting period, Greenko continues to (i) improve its operating efficiency by intense deployment of digitalization (ii) renovation of the existing assets (iii) deploy people, process, and systems to standardize operational responses and (iv) developing new skills, systems, and partnerships for focus on Pumped Storage with Intelligent Energy Platform (v) investment in cutting edge technologies and processes, to power our transformational journey towards GKO 4.0.

The transformational journey of Greenko, right from GKO 1.0 to GKO 4.0 is in synergy with the transitioning landscape of global energy systems, which is fuelled by the “3D” view i.e., Decarbonization, Digitalization, and Decentralization. This transition of energy system depends on increasing the integration of renewable energy in the grid and flexibility of the system while maintaining its reliability and performance. Greenko operates its business under this evolving context. Accordingly, Greenko has focused significant investment on the Integrated Renewable Energy Project as well as renovation and repowering of existing

Excellence, Adoption, and Managements of Assets and Projects The transformational journey of Greenko, right from GKO 1.0 to GKO 4.0 is in synergy with the transitioning landscape of global energy systems, which is fuelled by the “3D” view i.e., Decarbonization, Digitalization, and Decentralization. This transition of energy system depends on increasing the integration of renewable energy in the grid and flexibility of the system while maintaining its reliability and performance. Greenko operates its business under this evolving context. Accordingly, Greenko has focused significant investment on the Integrated Renewable Energy Project as well as renovation and repowering of existing assets through the deployment of digital technologies and value maximization programs. Operating efficiencies and effective management of generating assets are crucial to delivering flexible, schedulable, and reliable power to the stakeholders

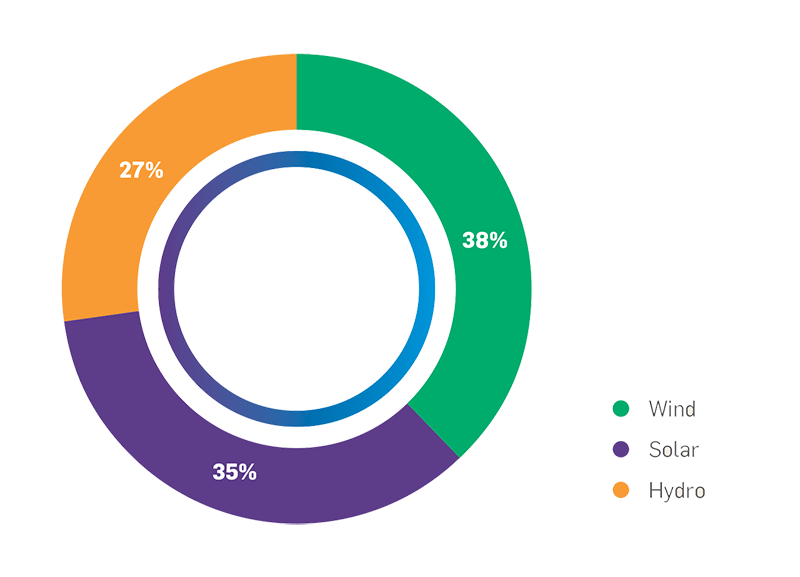

Greenko has a strategically diversified portfolio of assets by type, geography, offtakes, and technology employed. This diversification allows them for a yearlong generation as well as to build expertise by dealing with multiple stakeholders. To ensure the delivery of clean, reliable, and affordable energy, Greenko manages its diverse operating assets in accordance with the highest standards of performance, availability, and efficiency. The continuing excellence of operations provides a strong foundation for the ongoing transition of Greenko’s business.

In the current reporting period, the group continued to provide climate responsible, highly reliable and affordable electricity supply, thus contributing significantly to the transition towards a low-carbon economy. The energy generation infrastructure of Greenko has demonstrated considerable growth in scale with capacity addition of 1.4GW, taking the total installed capacity to 6.2 GW in FY 2019-20. The total capacity added includes inorganic growth through project acquisitions viz., a hydropower project of Everest Power Private Limited, with a total capacity of 100MW was added to Greenko’s portfolio and a definitive power purchase agreement was entered with Teesta Urja Private Limited, which has the underlying asset of 1200 MW of hydropower project.

In addition, a total of six projects are under construction with a licensed capacity of 254.5 MW, comprising one wind project with a licensed capacity of 20 MW, five hydropower projects with a licensed capacity of 234.5 MW. There are also 6 hydropower projects under active development with a total licensed capacity of 369.0 MW.

Total Installed Capacity

In addition, three IntegratedRenewable Energy Storage Projects(“IRESP”), the Pinnapuram IRESP, theSaundatti IRESP and MP 30 GandhiSagar Standalone Pumped StorageProject (SPSP), with a capacity of 8.7GW with the national grid connectivityare in development.

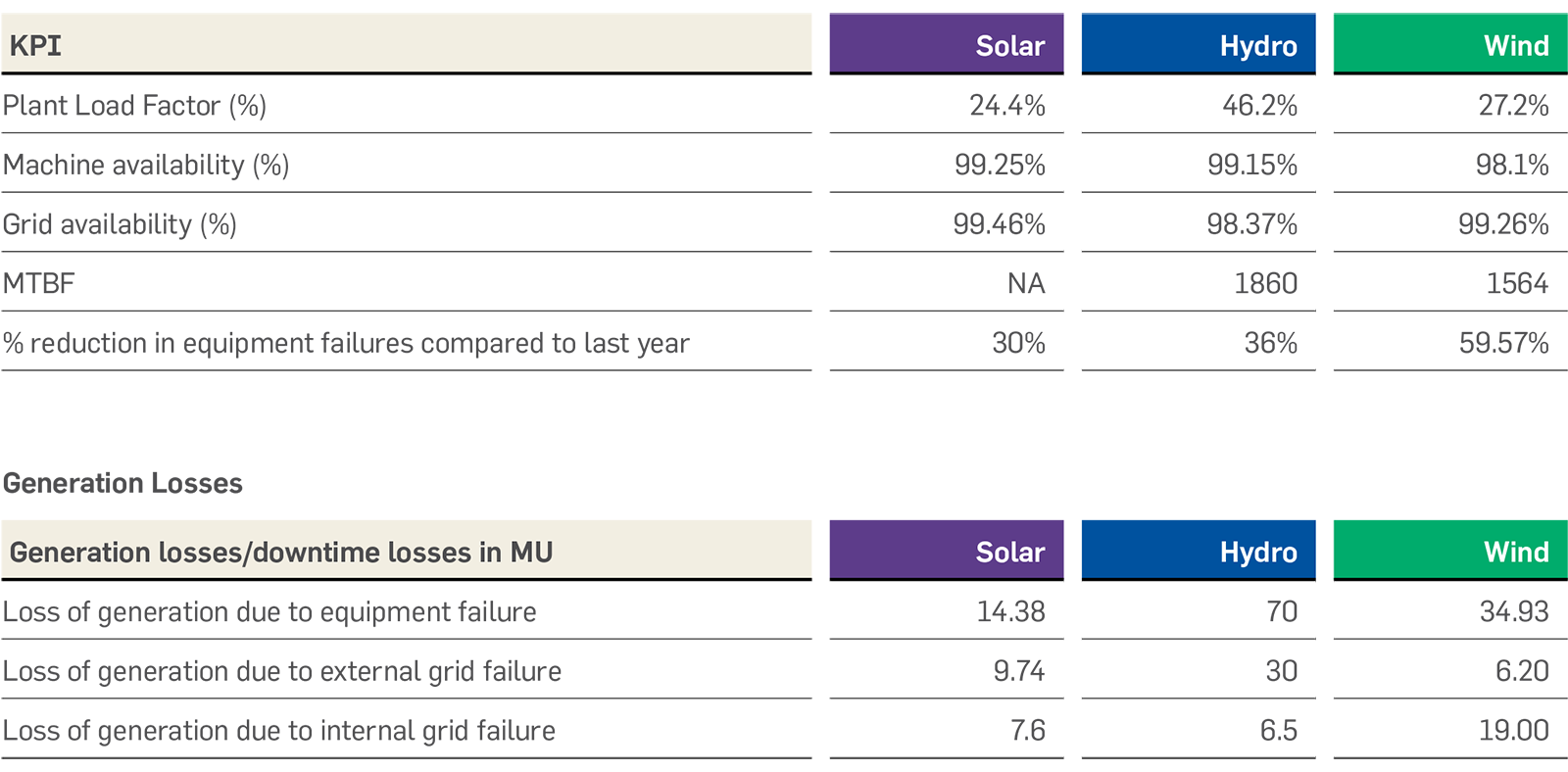

In the current reporting period, the total generation achieved has increased by 38.95% over the previous financial year to a total of 9969 GWh. The productivity of the operation demonstrated excellence with an increase of 0.80%, 9%, and 1.02% in solar, Hydro, and Wind portfolio respectively. A healthy Plant Load Factor (PLF), machine availability, grid availability was maintained in each of the renewable energy generation technologies viz. Wind, Hydro, and Solar, in complete sync with circularity aspects. In addition, the performance of the acquired assets has significantly improved in terms of efficiency and reliability in the reporting period.

Greenko’s ability to deliver reliable and affordable electricity depends on the continued efficient operation of its assets. The variety of skills and expertise housed by Greenko is the backbone of asset management capabilities to achieve excellence in performance.

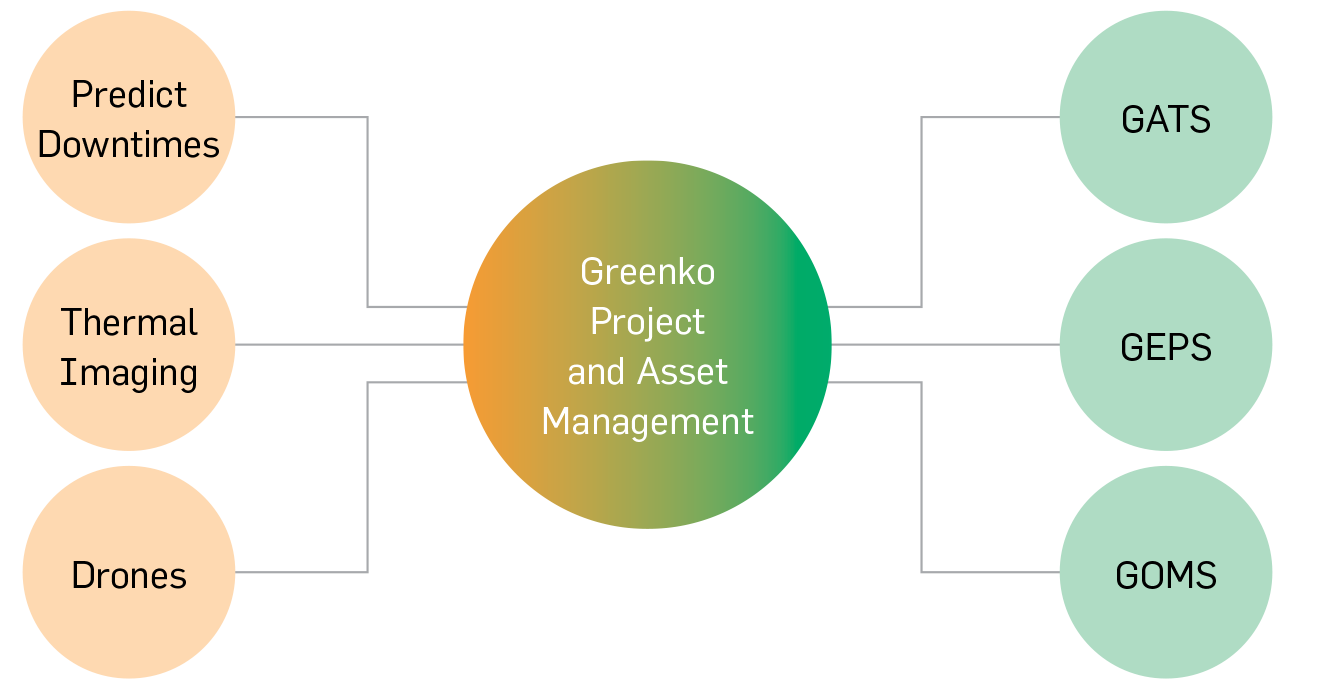

Operational excellence cannot be achieved without reliable, efficient, and continuously improving business systems. In this context, Greenko has established strategic asset and project management systems and processes under PPS (People, Process, System) which enables the organization to identify and prioritize enhancement or remedial work on its diverse generating assets. The systems and processes established by Greenko enhance visibility, control, and management of assets and projects to drive greater operational efficiency and effectiveness.

The analytical management systems deployed for tracking project and asset management are GEPS (Greenko Energy Project System) and GATS (Greenko Asset Tracking System). In addition to analytical systems, Greenko has employed predictive measures including aerial drone-based digital plant inspection which is an advanced technique for reliability and performance improvement. The digital inspection of rotor blades increased performance of up to 5%. It also improved the aero efficiency of the turbine blades significantly. Greenko has embedded a robust asset health monitoring and improvement practice through constant audit mechanisms which have greatly avoided many major component outages. Optimal operational performance is also ensured by adhering to 100% periodical and regular audit inspections which have resulted in overall asset availability.

Operation and maintenance (O&M) of Greenko’s large-scale infrastructure are benchmarked to industry best practices. GOMS (Greenko Operations and Maintenance System) is employed for Tracking of Maintenance activities and alert any form of deviation from schedule or quality

Components of Project and Asset Management

Greenko Energy Project Systems (GEPS)

GEPS is an in-house state-of-the-art project monitoring system tailored for real-time and agile project management, QA/QC, engineering, logistics, material management, and stores.

Value Creation Story

Objective

To improve Skerion assets WTG & Grid infrastructure and ensure Overall performance improvement.

Actions Taken

Major activities carried out

Key Benefits

In the past, the operation and maintenance activities of Greenko’s wind portfolio were solely handled by the Original Equipment Manufacturer (OEM). After a detailed analysis of risks and opportunities, Greenko had taken a decision to go for an in-source model for a limited identified wind asset, to maximize asset performance and quality by utilizing own resources in the current reporting period. This encouraged the participation of the group’s multiskilled employees, avoiding any stagnation of manpower and bringing in more independent approach for O&M.

Presently, five of Greenko sites under the wind portfolio, with a total capacity of 178.5 MW are covered under the WINSOM program. All the WINSOM sites demonstrated considerable improvement in performance and in capturing the missed opportunities to harness energy

Value Creation Story

Objective

To improve asset performance and quality and reduce O&M cost.

Location

Poly, Jed, Matrix, Mangalore & Orange Mamatkheda wind sites

Actions Taken

Outcome

The timely intervention on availability of spare parts and equipment maintenance as per the schedule, sometimes even before the schedule, avoided wear & tear of assets and improved its life and enhanced performance. The significant outcomes of the initiative are:

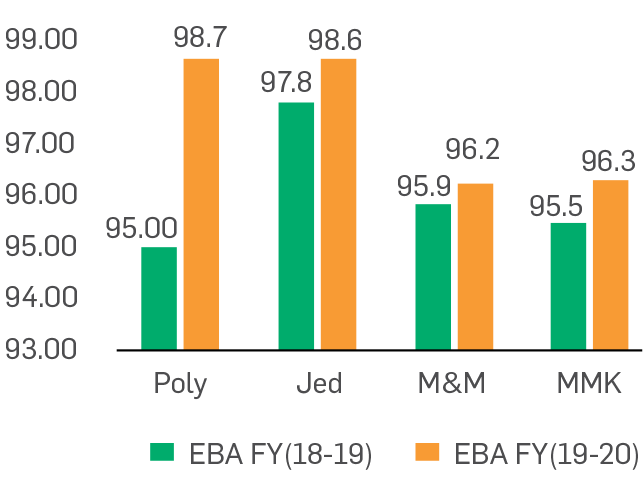

WINSOM Induced Performance Improvement

FY(18-19) Vs FY(19-20) EBA Comparison

The rapid increase of RE in the grid and its associated challenges gives rise to multiple values to generated electricity, which are increasingly encouraged and rewarded by the regulators. Greenko is driven in tapping such opportunities year on year.

Greenko has been an active participant in numerous carbon market mechanisms and government schemes from the beginning of its journey. In the current reporting period, Greenko has registered 22 projects under Clean Development Mechanism (CDM) projects with UNFCCC and generated 24,26,000 Certified Emission Reduction (CER) credits and 23 projects are registered under Verified Carbon Standard (VCS)

A 180 MW solar project and 9.6 MW Hydro project is being registered under the Gold Standard (GS). In addition, participating in the Indian government scheme, one solar, and three non-solar plants are registered under the REC mechanism and further registration of four solar plants and two non-solar plants are also under progress.

As we progress on implementing complex and novel technologies like Pumped Storage Projects and Intelligent Energy Platforms, quality becomes more critical and important than ever. Further, as these systems are for the long term, the quality parameters related to performance through life and flexibility for repair/reengineer/ remanufacture will become important. Quality assurance cannot be compromised for speed, cost, or innovation, and more so for projects that are executed to operate in an open environment and for a long time.

As we progress on implementing complex and novel technologies like Pumped Storage Projects and Intelligent Energy Platforms, quality becomes more critical and important than ever. Further, as these systems are for the long term, the quality parameters related to performance through life and flexibility for repair/reengineer/ remanufacture will become important. Quality assurance cannot be compromised for speed, cost, or innovation, and more so for projects that are executed to operate in an open environment and for a long time.

Greenko is expanding its asset portfolio significantly, year-on-year, to drive its transformation towards GKO 4.0 and this journey is possible only by maintaining high standards of quality and efficiency. In line with a commitment towards excellence, Greenko’s Quality Management Department (QMD) has established and implemented a strategic management plan for Quality Assurance and Control of assets.

The Quality Management team of Greenko has a vision of “Maintaining uncompromised quality standards in building and operating energy assets”. This vision enables the team to determine its focus areas, methodologies, and processes, integrate quality control elements into decisive phases of the project through strategic level policies and operations that are required to be implemented to address the complexities of a project. Strategic plans are developed to ease these complexities.

Strategic elements that are described in this plan consist of the team’s interactions with aspects such as Policy & Objectives, Context Management, Project Organization, Communication Management, Design, and Engineering Management, Vendor Management, Quality Control and Assurance, Audit Management, Deviation Control, Document Management, Training, IT Management, and HSE Management.

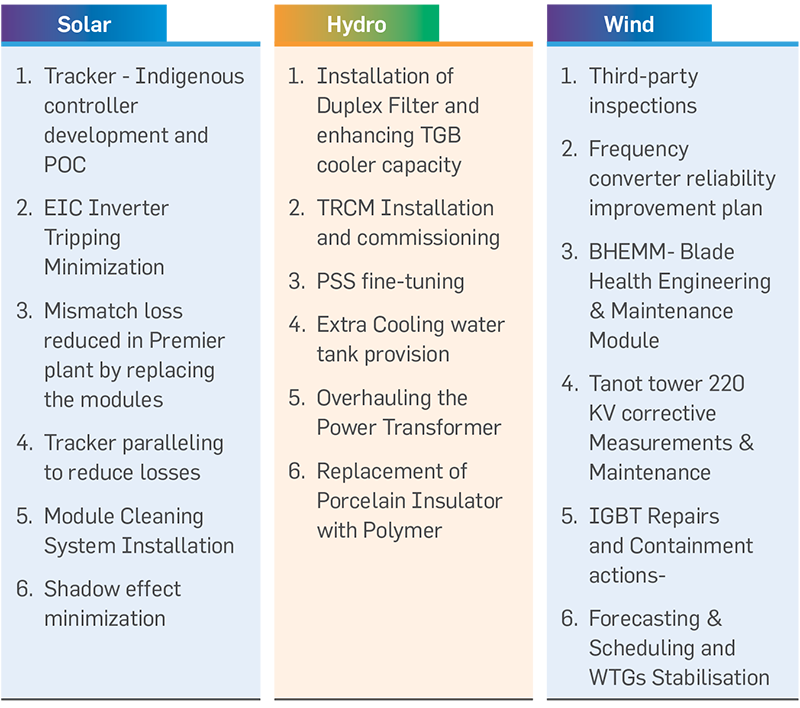

To achieve the highest standards of operational performance, Greenko has identified and implemented several energy efficiency initiatives and Value Maximization Programs across its operating portfolio. The initiatives carried out in the current reporting has increased the generation significantly.

Value Maximisation Initiatives across Portfolio

Value Creation Story

Objective

Minimization of consumption from the grid to reduce transmission line losses and related expenses.

Location

Axis Wind Farms (MPRDAM) Pvt Ltd, Anantapur, AP

Description

In calendar year 2018, grid import of the site was 0.443 MU and its expenditure was Rs. 5.504 Million. The site, through root cause analysis and other problem-solving methods, identified solutions to minimize the grid consumption. By tuning power factor setting of wind turbine generator at low wind to 0.985 and at high wind to unity, import grid electricity and line losses were controlled during low wind period.

Reduction of transmission losses was achieved by maintaining higher voltages on 33 kV Side i.e. greater than 33.5 kV. By maintaining higher voltage on the power transformer’s low voltage side at PSS during high wind, Greenko was able to reduce I2R losses of the transformer. Further, the power transformer’s full load losses were reduced by 3% due to the decrease in current.

Value Creation Story

Objective

To avoid major breakdown of wind assets by tracking the health of the main bearing and avoiding failures during high wind Season.

Location

FFHPPL, wind site, Vijayapura

Description

Root cause analysis was conducted to identify the issues in the main bearing. CBM (Condition based monitoring) method, which is identified as the best tool to track such problems, was employed to detect the anomaly in the main bearing. By addressing the detected anomaly, major breakdowns in the high wind season is avoided, thereby ensuring improved generation and health of the wind turbine generator. A dedicated WTG main bearing repair and replacement centre was also temporarily constructed at site level for quick restoration.

Actions Taken

WTG Main bearing repair and replacement centre temporarily constructed at site level for quick restoration.

Key Benefits

Outcome

Harnessed full potential of wind resource

Value Creation Story

Objective

To avoid generation losses and system failure by adopting an innovative idea of tracker drives system protection

Location

Pavagada Solar Power Plant, Karnataka

Description

The emergency push button is placed beneath the PV Modules and the regular tilt setting is kept up to 45° for both the directions viz., East & West Side (- 45° & 45°). If the limit switch or PLC programme fails, the emergency switch will be activated beyond the setting limits in both directions, thus protecting the tracker drives system and the modules.

Actions Taken

Limit switch modification was done

Key Benefits

Outcome

Post successful demonstration, 239 tracker systems were installed in 3 sites.

Value Creation Story

Objective

To enhance the coolers’ capacity in the cooling water system of Turbine Guide Bearing (TGB) by Installation of Duplex Filter.

Location

Greenko Budhil Hydro Power, Chamba, Himachal Pradesh

Description

The plant was facing problems with choking of the TGB coolers during the peak generation period (Monsoon Season) and experiencing forced breakdown due to rise in temperature of the TGB. Thus, resulting in generation loss due to planned outage of at least 1-2 hrs for cleaning of the TGB coolers. It also damaged the mechanical seal of booster pumps.

Root cause analysis was conducted, and it was found that increase in silt levels to 2000 ppm during the monsoon season was the reason of the choking. Corrective measures were taken through installation of duplex filter, with filters of 40 micron in the cooling line of TGB, before the booster pump, to achieve the maximum generation. Installation of the Duplex filter decreased the silt content in the TGB cooling line from 74 microns to 40 microns. The system is now operating successfully

Key Benefits

Outcome

Improved operational efficiency and asset life

Value Creation Story

Objective

Checking the health and performances of PV modules in real time at site.

Actions Taken

An in-house solar panel testing has been established at our Kurnool site to check the health and performance of the PV modules.

The facility consists of two most important equipment i.e. Electroluminescence machine and Sun Simulator Machine.

Electroluminescence (EL) Machine

The main goal of the electroluminescence test Using EL machine for the solar panels is to detect the malfunction in the junction boxes of modules. The PV modules are brought into laboratory and their health is checked at the time of installation and during operation and maintenance.

Sun Simulator Machine

Solar Simulator machine simulates air mass (AM) 1.5 and use xenon lamps to generate light to test PV modules. Solar simulator provides electrical performance of PV modules at standard test condition. The sun simulator is used for checking module quality and it also verifies eventual power losses in the modules. Solar Flash Test (Sun Simulator Test) is being conducted using Sun Simulator Machine to measure the output performance of a solar PV module to ensure the conforming operability of each PV module.

Key Benefits

Value Creation Story

Objective

To ensure quality of the concrete while preparing it in extreme weathering conditions.

Actions Taken

Greenko has undertaken projects works in extreme cold conditions and as well as extreme hot conditions. During constructions of Tanot Wind Project in Rajasthan state and Vaishali wind project in Karnataka state the summer temperatures were more than 40 °C.

During construction of The Sorang Hydro project in Himachal Pradesh the ambient temperature during winter is less than zero.

Concreting during hot weather conditions cause the concrete to gain high early strength but consequently gain less strength in the later stage resulting in lower durability of structure. If the ambient temperature is too low, the hydration of the cement will significantly slow down, the concrete will have a reduced overall strength and will cause cracking due to ice formation.

So, our QA/QC Department has conducted experiments to study various methods and options to achieve enough quality in the concrete at extreme temperatures.

Following are some of the mitigative measures identified to be adopted at the sites in extreme temperature conditions.

At extreme hot conditions

At extreme cold conditions

Key Benefits

Concreating can be done in the extreme weather conditions (day & night) to expedite the construction work without compromising the strength and thermal cracking of concrete.

Hot Water poured to Aggregate during cold condtions

Ice cubes added to water during hot weather

Measuring temperature of concrete during extreme weather conditions

Greenko drives operational excellence by maintaining and continuously improving contracts and procurement excellence. It contributes to organizational objectives, manages supply chain risks through effective collaborations and competitiveness, and is supported by best-in-class technologies. The group’s contract and procurement functions are centralized and place great emphasis on quality, cost efficiency, and resilience.

Greenko’s Contracts and Procurement management contributes meaningfully to the organization’s business economic strategy and its business plan through responsible, transparent, and effective procurement services which offer value for money, is legally compliant, and follows best practice. The C&P department aligns every business sourcing activity to the group’s organizational goals and objectives. This allows the group to achieve higher business performance with improved efficiency and minimal supply chain risks.

The C&P team procures all goods and services for Greenko Energy Projects (GEP) and Greenko Assets Management (GAM) with high quality and ethical standards focused on social, economic, and environmental considerations and appropriate risk mitigation processes.

Greenko balances short, medium- and long-term benefits to the business and its partners and negotiates the techno commercial attributes and delivery schedules within the targeted price. The group formulates appropriate procurement strategies by evaluating the long-term needs of business units, as well as supply-side market opportunities and risks. This coordinated approach has increased Greenko’s ability to negotiate improved terms from suppliers and manage risks, resulting in tangible commercial benefits for the Group.

Greenko further enhanced its management of procurement in the reporting period, by employing innovative contract structures for its IRESP projects. In addition, in line with the sustainable procurement practice at Greenko, the C&P team is driven to embrace circularity in its practices, and accordingly measures are under planning to extend the life of our assets and to address the end of life through the goods and services procured.

With the global energy system going through a rapid and radical transition towards Decarbonization, Digitalization and Decentralization, the importance of establishing Intelligent Energy Storage cannot be overstated. The inherent infirm and non-schedulable nature of renewable energy generation presents a huge challenge for integrating large RE capacities while maintaining grid stability. Integrating Wind and Solar energy with time tested and proven Pumped Storage Solution presents an optimal, economically viable, and scalable option to supply Schedulable Power On-Demand (SPOD) with both baseload and peak load capabilities. Renewable Energy plus Storage Projects (RESP) enable firm, flexible, schedulable, and round the clock generation of energy. In addition, it also effectively addresses the challenge of ramp-up / ramp-down requirements. The combination of renewable energy sources such as solar, wind, and pumped-hydro storage allows uninterrupted supply of electricity that is not affected by temporary shifts in weather and costs equivalent to fossil fuel-based energy

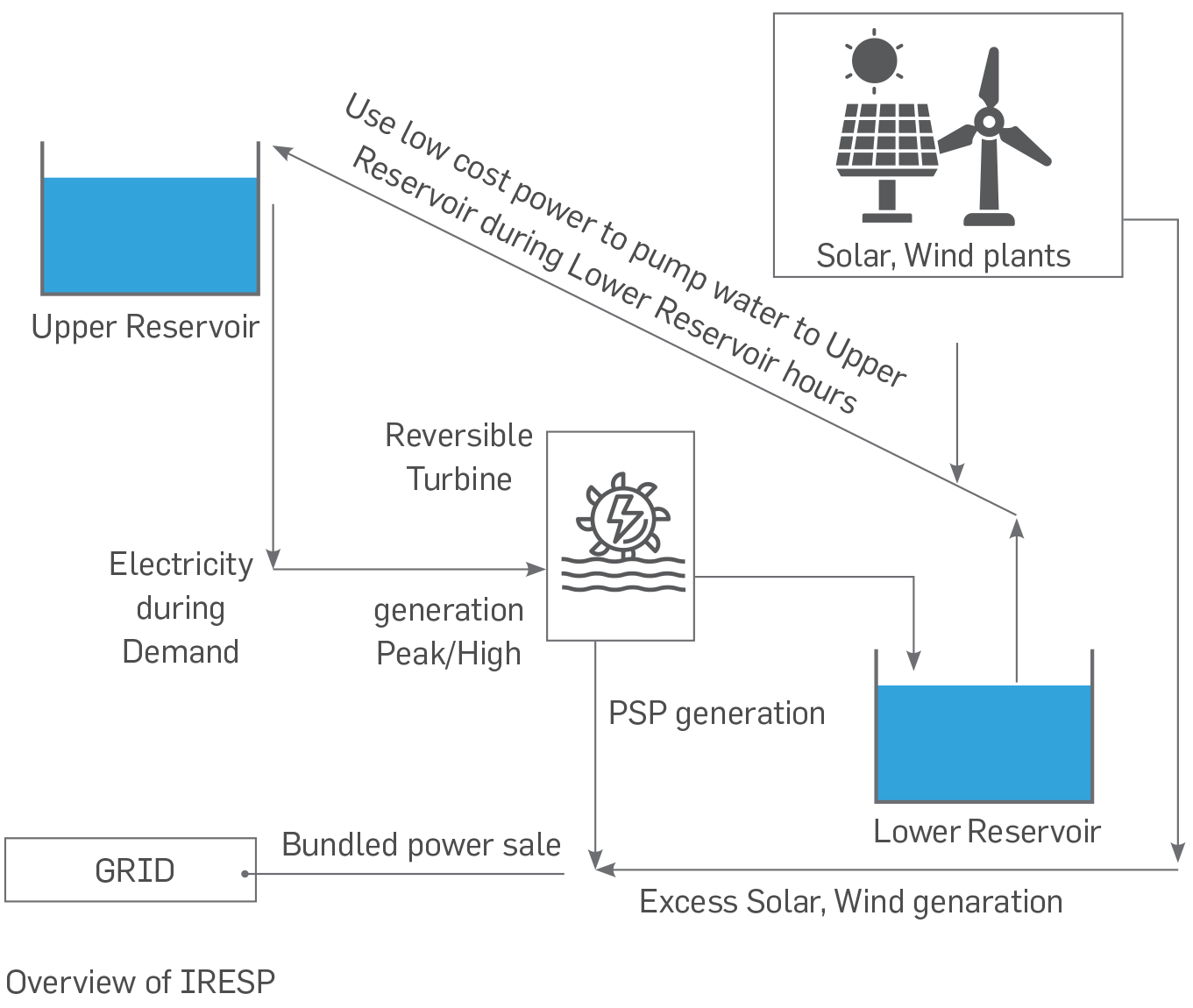

Pumped storage hydropower project comprises of an upper reservoir and lower reservoir interconnected with a waterway, a powerhouse which contains hydropower electrical mechanical equipment, and a transmission connection to the grid. This project is operated when inexpensive electricity is available (which is typically available at night or on weekends when power demand is low or in case of excess solar generation in the daytime) is used to pump water from the lower reservoir to the upper reservoir. Water stored in the upper reservoir is then released during peak demand periods, delivering more valuable electricity to the grid. With the introduction of renewable energy technologies, the operation of pumped storage hydropower facilities is being expanded to utilize excess energy from renewable energy systems for later use during peak demand periods.

The following diagram provides an overview of the operation of an IRESP:

IRESP Model

Pumped Storage solution provides the necessary scale of energy storage and life cycle, resulting in affordable SPOD energy over the life of the projects. Developing such Integrated Renewable Energy Projects in Wind and Solar resource-rich locations along with standalone Pumped Storage capacities, without impacting the existing natural systems is necessary to sustainably power the future needs of our country while maintaining grid stability.

Pumped storage hydro Power Project (PSHPP) provides a zero-emission alternative to conventional carbon emitting thermal plants. Generating capacity can be quickly dispatched and ramped up to meet demand, compensate for large swings in intermittent generation power injection and provide contingency reserves to compensate generation unit outages.

The advantages of PSHPP are:

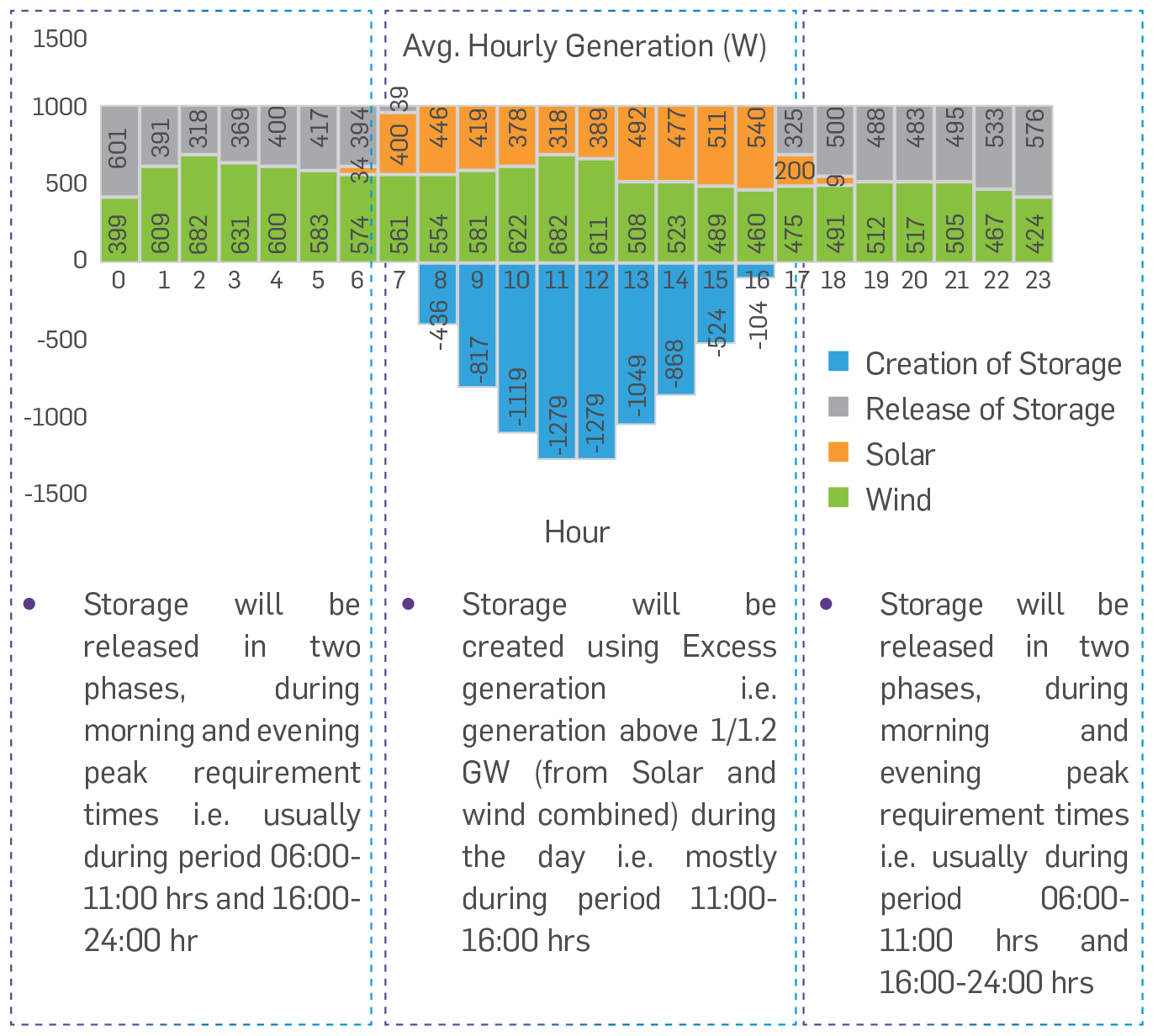

The IRESPs are expected to harness the power of solar and wind resources with digitally connected storage infrastructure to provide scheduled and flexible power to the grid. The pumped hydro storage system provides scale and cost competitiveness.

The IRESPs will be able to provide on-demand power which can be scheduled based on peak and base load requirement, thereby assisting with grid balancing. IRESPs are highly efficient with limited storage loss and can provide DISCOMs with ancillary storage and grid balancing services. The IRESP would also allow us to provide offtakers with flexible contract structures to suit their needs.

Following is the description of integration of solar, wind and pumped storage projects in providing the schedulable on-demand power.

Greenko has planned to develop Integrated Renewable Energy projects with a total capacity of 40 GWh across5 states of India, out of which three are currently in the pre-construction phase viz., the Pinnapuram IRESP, the Saundatti IRESP, and MP 30 Gandhi Sagar Standalone Pumped Storage Project (SPSP) in the states of Andhra Pradesh, Karnataka and Madhya Pradesh respectively, has a total capacity of 8.7 GW. The IRESPs are expected to harness the power of solar and wind resources with digitally connected storage infrastructure to provide scheduled and flexible power to the grid.

Greenko’s business model of Pumped Storage Plant combined with the Intelligent energy Platform contributes greatly to the circularity of economy and energy security by creating new sharing platforms in the sector.

Pumped Storage Plant Model

Greenko Group has conducted detailed research and evaluated suitable locations for IRESPs in India and has identified Pinnapuram, Kurnool District, Andhra Pradesh for the proposed Pinnapuram Integrated Renewable Energy Storage Project (IRESP). Pinnapuram IRESP has been conceived as the Largest Gigawatt Scale integrated project with solar, wind and pumped storage components that can supply Schedulable Power on Demand (SPOD) which is Dispatchable & Schedulable Renewable Energy for the first time to consumers across India.

The Pinnapuram IRESP consists of four key components which are as follows,

All four components of Pinnapuram IRESP are in close vicinity of each other and therefore power from PSP, Wind and Solar sources will be commonly pooled.

CPSS is connected to evacuate energy nationally to multiple interstate consumers. Greenko Renewable Energy Management Centre housing the “Intelligent Energy Platform” (to forecast, monitor, balance, and deliver the required energy and storage services) will be an integral part of CPSS.

The IRESP Project is a self-identified project which can meet the dynamic needs of DISCOMs/STUs thorugh:

Greenko’s second Integrated Renewable Energy Project is planned to be developed at Saundatti, Karnataka, with a Standalone Pumped Storage Project (SPSP) of 1260 MW generation capacity, 9-hour storage, resulting in a daily storage capacity of 11.3 GWh. The project is currently in the design phase and is planned to have similar components and design features as that of the Pinnapuram IRESP.

The Saundatti Integrated Renewable Energy Project is also designed as a gigawatt Scale integrated project with solar, wind and pumped storage componentsa

The four key components of the project are:

The Standalone Pumped Storage Project (SPSP)

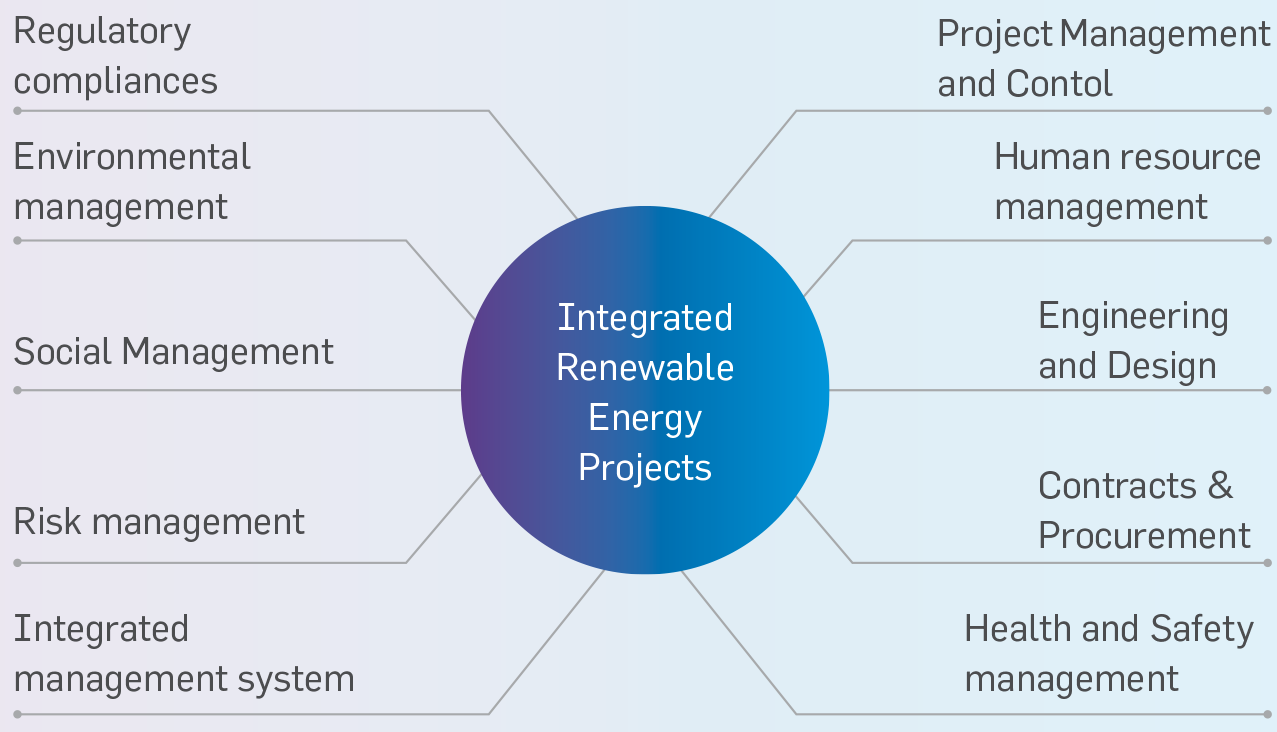

For managing the IRESP, Greenko has a disciplined project management team and has developed a technologically advanced project management system. In project management, Greenko follows a detailed process of self-discipline and agility throughout the stages of Initiation, Planning, Execution, Monitoring and Control and Closing. The following is the brief description of the Project Management functions which are geared to achieve the target of completing the project within 3 years.

Greenko has created PMC for governing the processes, practices, tools and other activities related to project management. PMC defines and maintains the standards for project management, monitoring and controlling the entire process of project management from Initiation to Closing of each project.

As the renewables share in the grid grew, the hydro and its storage ability has come back to the fore, albeit in a new format. We are sensitive to the skill gaps that we may encounter in implementing these projects and accordingly have taken action proactively. We want the project completed on an accelerated schedule and we are prepared to face challenges that come with this expectation.

As the renewables share in the grid grew, the hydro and its storage ability has come back to the fore, albeit in a new format. We are sensitive to the skill gaps that we may encounter in implementing these projects and accordingly have taken action proactively. We want the project completed on an accelerated schedule and we are prepared to face challenges that come with this expectation.

The pumped storage project is material-intensive and we are aware that circular approaches have significant applications in the design, engineering, and construction. We have begun exploring options to minimize the external material use and whenever such material is used, we are sensitive that it will have to decommission after the long project life. In the design and construction, provisions are made for extending life through reengineering or refurbishing.

The pumped storage project is material-intensive and we are aware that circular approaches have significant applications in the design, engineering, and construction. We have begun exploring options to minimize the external material use and whenever such material is used, we are sensitive that it will have to decommission after the long project life. In the design and construction, provisions are made for extending life through reengineering or refurbishing.

Greenko has an advanced human resource management system which looks after how the Project will acquire, develop, and manage human resources throughout the Project life cycle. For IRESP, HR department has prepared a project plan which identifies and describes the processes that will be used to plan and acquire employees, train, track and ensure transition. The responsibilities of the staff are delineated and managed using the staff management process.

The key management team members, who are highly agile, diverse and experienced, involved in the IRESP project management are:

Greenko believes that continuous learning is an indispensable tool for the growth of the organization. In this context, HR Projects has conducted a “Executive Development Training program” on IRESP Construction Methodology and Project Management with reference to all the project knowledge areas including Safety, Quality, Cost and Time management. There were 45 sessions, 3 Batches and 150 + participants. Employees from 24 locations, Pan India, from operating sites and the Head Office participated in the training, covering 450 Man-days and 3150 Manhours.

The training was delivered by highly qualified and experienced faculties from National Institute for Construction Management and Research (NICMAR), Hyderabad.

We build Flexible, Innovative, ResultsDriven Teams for handling multi-GW scale IRES projects.

We build Flexible, Innovative, ResultsDriven Teams for handling multi-GW scale IRES projects.

IRESP Construction Methodology and Project Management Training

The Pumped Storage Platform is being engineered and designed completely on futuristic global business objectives of Renewable Energy parks as an Intelligent Energy Platform. Greenko aims for optimal capacity utilization of the two energy components of the IRESP viz., Solar & Wind. PSP is being designed to operate with a wide range of operational flexibility, faster active and reactive power adjustment, quick reaction time and higher efficiencies to meet the grid requirements.

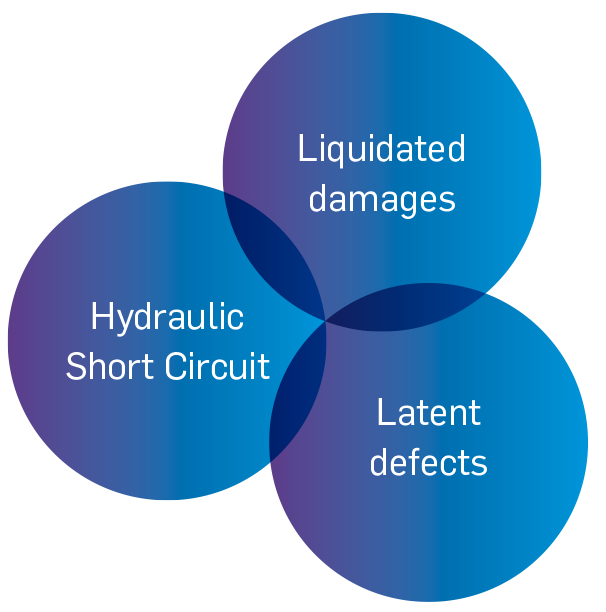

PSP is planned to employ an Adjustable Speed design with Double Fed Induction Motor Generator to operate at its peak efficiency points under all head conditions to achieve a substantial increase in energy generation. The hydraulic short circuits feature two small units and enables mitigation of optimum power handling feature in the range between unit capacities. The PSP will be connected to the customer’s grid through the Centralized Load Dispatch Centre of the IRESP to optimize energy export.

The flexibility of pumped storage hydro has been historically constrained by the interaction of the turbines, the dam, the water flow, and the institutional agreement. With adjustable speed or ternary units, the PS project can not only supply load following but, can become one of the fastest response stations on the power system. It can offer frequency regulation, whether pumping or generating and can allow pumping at less than full load, thereby increasing the flexibility.

The flexibility of pumped storage hydro has been historically constrained by the interaction of the turbines, the dam, the water flow, and the institutional agreement. With adjustable speed or ternary units, the PS project can not only supply load following but, can become one of the fastest response stations on the power system. It can offer frequency regulation, whether pumping or generating and can allow pumping at less than full load, thereby increasing the flexibility.

The procurement of equipment for IRESP is novel and challenging. Therefore, the C&P strategy employs International Competitive Bidding (ICB) as an innovative contracting structure that not only allows sharing of risk and opportunities among partners but also makes the complete process transparent. This has enabled Greenko to effectively secure smart contract agreements, in line with the IRESP requirements. In addition, new C&P processes specific to IRESP were also designed and established in the current year.

In the current reporting period, QMD of Greenko has ventured into and established novel practices, QA/QC processes, technological tools, and innovations to ensure high standards of quality while prevailing over the challenges of complexity, flexibility, and scale. For this purpose, Greenko has planned to use EPC (Engineering, Procurement, and Construction) lifecycle stage quality elements of an IRESP, as a basis to establish controls to be adopted at each stage.

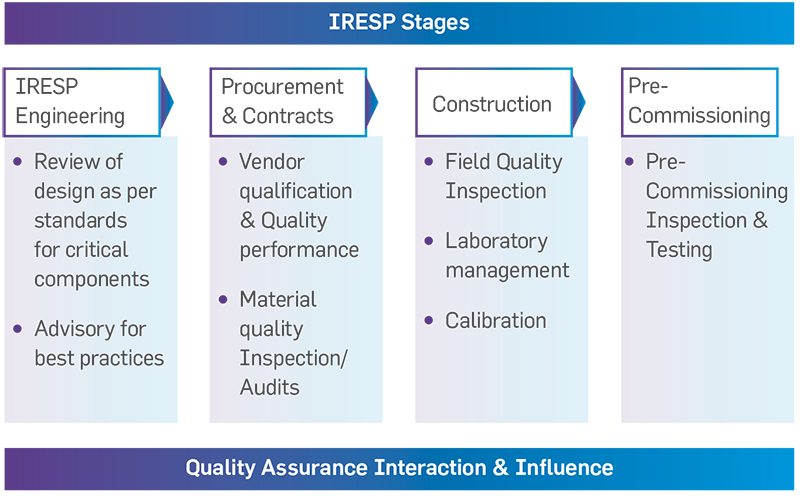

Best practices in quality assurance at all stages of the IRESP project construction are adopted. QMD has mapped interaction and influence areas for key stages of IRESP, such as Engineering, Procurement, Construction, and Pre-Commissioning.

Throughout the stages, these interactions are interlaced with the IRESP design and construction. These interactions are then cascaded in terms of the controls to be carried out by the QMD function during the task implementation.

In addition, Greenko has prepared a “Quality Assurance Handbook”, consisting of Civil, Electrical, and Mechanical testing procedures. These procedures are prepared based on National and International standards and codes adopted to the requirements of Greenko. The interpretation of these standards and codes in a simple and understandable way provides working flexibility within permissible limits to the field quality engineers.

Greenko has also established specific QA/QC metrics to measure and manage IRESP. SMART (Specific, Measurable, Achievable, Realistic/ Reasonable, and Time-bound) objectives are also established for each target.

Timely clearance of material inspections

Timely response to field quality requests

Minimization of IRESP quality risk

Minimization of quality complaints from internal and external stakeholders

Adherence to all applicable quality standards

Continual improvement in effectiveness of the strategic quality plan implementation

Digitalization and Decentralization

The role of quantity surveying department starts from the inception of the project, from preparing optimal quantities, preparation of initial project cost & cost planning to advising the ideal contract model. It also manages project spending / dispensing / payment recommendation as per the work done, with clear documentation targeting audit readiness. The eventual surety of the function is to close all the accounts / contracts along with closure of the project and releasing securities after successful compliance to involved warranties.

Greenko understands that risks are inevitable while undertaking Construction projects. The project manager at Greenko analyses risks and accordingly, controls are implemented to keep the risk level at nil or minimal.

Greenko plans their strategy based on the following four steps of risk management which prevails in Greenko project management.

Being one of India’s leading independent power producer focusing on renewable energy resources, sustainability is one of the key attributes endorsed by Greenko Group. It seeks to protect our natural environment, human and ecological health, without compromising our way of life; including cross-cutting issues such as gender equality, community empowerment, and social accountability. While ensuring sustainable growth through economic and social development, and protection of environment; the primary responsibility of this department is to ensure Greenko Group’s compliance to all applicable Environmental & Social (E&S) regulatory frameworks adopted by the Indian Government and/or to which the Government of India (GoI) is a signatory. Alongside, the ESMS department is also mandated to ascertain E&S considerations adopted by International Financial Institutions and it is addressed judiciously during project financing.

Therefore, with a view to understand and manage environmental, social and corporate governance (ESG) issues, Greenko Group conducts detailed Environmental Impact Assessment (EIA) and Environmental & Social Impact Assessment (ESIA) studies.

As the department is mandated to comply with both, regulatory as well as non-regulatory requirements, Greenko Group has embarked on holistic approach in complying with E&S issues arising due to proposed developmental activities, particularly development Pumped Storage Projects.

The environmental and social governance framework adopted by Greenko Group is presented below. Although regulatory and non-regulatory framework for managing E&S issues may vary, the fundamental components of EIA and ESIA involve following stages:

Integrating the principles of sustainable development into Group policy presents a major opportunity as well as challenge. However, achieving this goal by adopting a framework on EIA and ESIA will reinforce use of integrated, cross-sectoral, and comprehensive approach in guiding the design and implementation of Integrated Renewable Energy Storage Projects (Solar, Wind and Standalone Pumped Storage) of Greenko Group.

Greenko is committed to ensure a safe and healthy environment for all employees to work in. Greenko prepares a Project Specific Health and Safety plan to protect the health and safety of personnel working in the project. All subcontractors, visitors or consultants must adhere to the provisions of this Health and Safety Plan.

Greenko believes that: All accidents are avoidable, everyone is responsible for assisting with accident prevention at his or her own level on site, Safety training is essential, Prevention is an integral part of the project management approach.

Greenko Project Management commits itself to the above philosophy and Greenko sets the objectives and targets for all its project to implement and achieve this. This is to ensure Legal Compliance, the minimisation of risks and the protection of the workforce and persons affected by company activities.

General Medical & Eye Camp, Devgarh

Greenko believes that using and reusing resources as efficiently as possible and finding value throughout the life cycles of finished products, significantly increases the productivity of the resource and thereby, reduces the cost while preserving and enhancing the natural capital. In this context, Greenko has adopted circular economic principles in managing organizational assets.

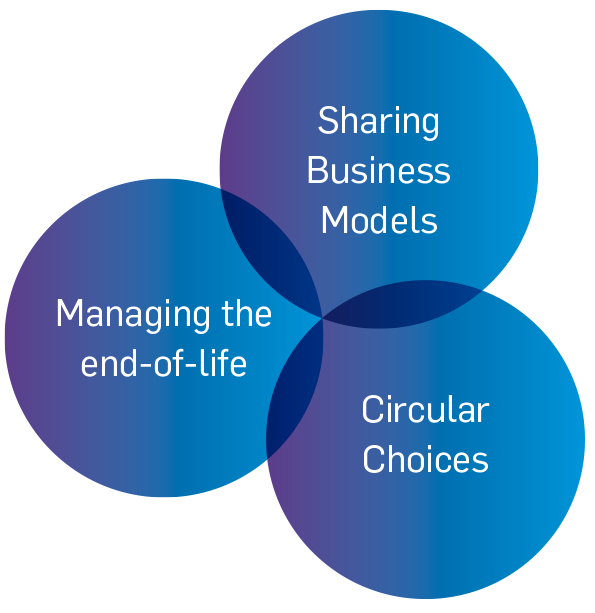

Greenko has explored circular value pools across its business by deploying a life cycle approach to business. Circularity at Greenko is harnessed at three levels.

The first is the deployment of Sharing Business Models. IRESP projects are major sharing platforms of storage and other electricity system services. The group has been working and implementing the sharing generation asset model as also sharing of resources on the margins of the electricity grid.

The next circularity approach is Circular Choices. During the reporting period, Greenko has exercised caution while designing and making equipment choices keeping in mind how long these assets will deliver value. This renewed focus on extending the asset life has become now a salient part of our asset management. In addition to design and equipment choices, the existing asset

life is extended through upgradation, modernisation and periodical maintenance. In this context, Greenko has teamed up with ONYX InSight, a leading global predictive analytics and engineering firm, to modernize and upgrade 500 wind turbines.

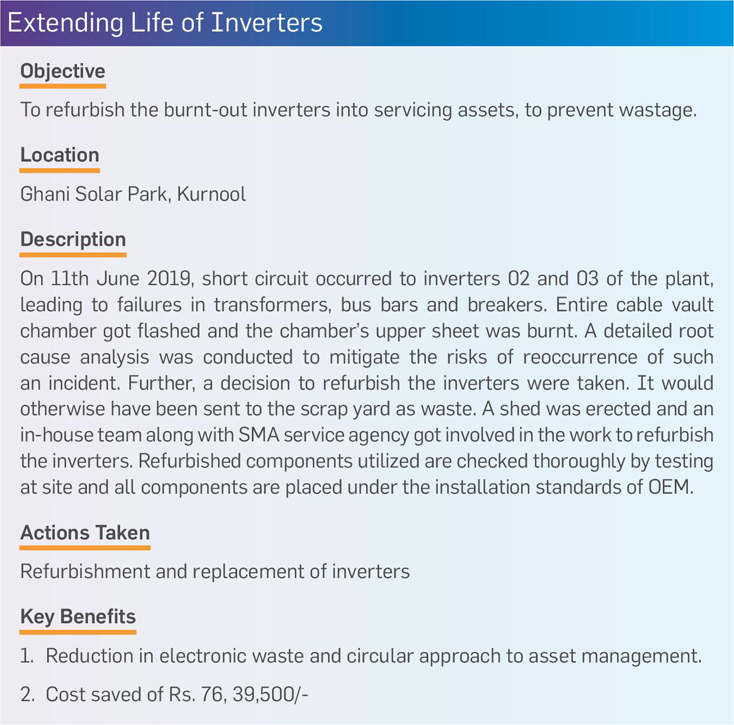

The third and final element of Circularity at Greenko is Managing the End of Life of assets and ‘everything else’. Managing ‘everything else’ at end-of-life was practiced always by the organization’s waste management team. They are now charting out ‘second life’ for each of our assets and their parts at their end of life in the assigned role. In this context, in the current reporting period, burnt-out inverters of solar assets were refurbished to extend the useful life of the components and to reduce the waste generated. In addition, final disposal methods and quantities of material post its ‘second life’ is recorded.

Development and establishment of Standard Operating Procedures (SOPs) for the circular economy model are under process for all functions of Greenko currently. The efforts taken in the current reporting period to improve the asset life are summarised below,

Greenko is progressively and strategically expanding its asset portfolio with nearly 8GW of capacity in its pipeline and this would contribute significantly to achieve the Group’s goal of reaching 30 Billion Units electricity by 2023.

Continuous and improved emphasis will be placed on the stages of execution of the IRESP projects, through upskilling of the project team, enhanced technological capabilities in design and construction of the project and improved resource efficiency, to achieve high standards of quality in delivering schedulable, RTC energy. The focus on energy efficiency and cost optimization through technology deployment and value maximisation programs will continue. This will be achieved through skill acquisition, new processes and systems and qualitatively different partnerships.

The O&M capabilities and capacities will be enhanced in house and these will be extended to include predictive and adaptive methodologies through application of Digitalization. This drive in the coming years will supplement our capacity to extend the life, plan for second life and manage the end-oflife of products. Further, predictive and adaptive capabilities will have an aim of climate proofing assets against variation in resource availability.