Greenko recognizes that

the accumulated GHGs in

the atmosphere and the

additions till 2050 will effect

changes in the climate.

Greenko recognizes that

the accumulated GHGs in

the atmosphere and the

additions till 2050 will effect

changes in the climate.

At Greenko, from the inception, combating climate change is the salient purpose of our business. Our asset portfolio of renewables, during the reporting period, has avoided 8.2 Million tons of CO2 emissions. We understand the limitation of infirm renewables to displace nonrenewables that generate firm power and have some flexibility. To overcome this barrier, we are harnessing digitalization and deploying the Intelligent Energy platform and putting together multiple pumped storage projects located and designed strategically across the country to harness different value pools in the electricity system. This initiative aided by the evolution of a favourable policy ecosystem to deepen decarbonization and technological developments in renewable energy that brought in price parity of generated electricity will deliver clean electricity.

Our founders at the time of inception and thereon, always reminded us that the renewable electricity system can only be part of the solution. It can only reduce the emission by 55% by 2050, as eloquently argued by Alen Macarthur Foundation. The NET ZERO target is achievable only if non-electric uses are addressed and circular economic approaches are adopted. Many elements of Greenko 4.0, would address this challenge by working with industry and business to address their climate targets viz., Science-Based Targets, or RE 100. Further, Greenko is exploring the role it can play in renewable electrification of the transport sector. The decarbonization of the electric system and electrification in the manufacturing and transportation sector will still leave a gap to achieve NET ZERO by 2050.

It is for this reason, the leadership of Greenko included a circular economic strategic approach in our value creation model, beginning this reporting period. We have explored circular value pools across our business by deploying a life cycle approach to business. Circularity at Greenko is harnessed at three levels. The first is the deployment of Sharing Business Models. Our IRESP projects are major sharing platforms of storage and other electricity system services. We have been working and implementing the sharing generation asset model as also sharing of resources on the margins of the electricity grid. Our next circularity approach is Circular Choices. During the reporting period, we have exercised caution while designing and making equipment choices keeping in mind how and how long these assets will deliver value. This renewed focus on extending the asset life has now become a salient part of our asset management. Further, our teams are including circular approaches in SOPs of design, procurement, and asset management. To extend the life and enhance the performance of some of our wind assets, modernization and upgradation of 500 wind turbines is initiated during the reporting period. The third and final element of Circularity at Greenko is Managing the End of Life of asset and ‘everything else’. Managing ‘everything else’ at the end-of-life was practiced always by our waste management team. They are now charting out ‘second life’ for each of our assets and their parts at their end of life in the assigned role. They are also recording the final disposal of material post its ‘second life’.

Greenko is committed to making decarbonization- NET ZERO by 2050, a reality, and will continue to have this as a purpose of the business. Our Climate Vision 2050, include Only Renewable Assets, Decarbonise Electricity grid, Electrify Energy, and Circular Electric Systems

Further, Greenko recognizes that the accumulated GHGs in the atmosphere and the additions till 2050 will effect changes in the climate. Our assets and their generation could be impacted and it could have a financial implication. Also, the transmission infrastructure may be impacted due to extreme weather events that may disrupt infrastructure or significant short-term changes in electricity demand. We have mapped the physical climate changes that could occur across our sites and the impact on the business. We have also charted out the climate risk mitigation plan which includes engineering measures, changes in standard operating practices, and insurance. We would also make the climate risk a constituent of Enterprise Risk Management in the coming years. The assessment of climate risk to generation assets, T&D infrastructure, and electricity demand, would also inform our choices of locations in our growth.

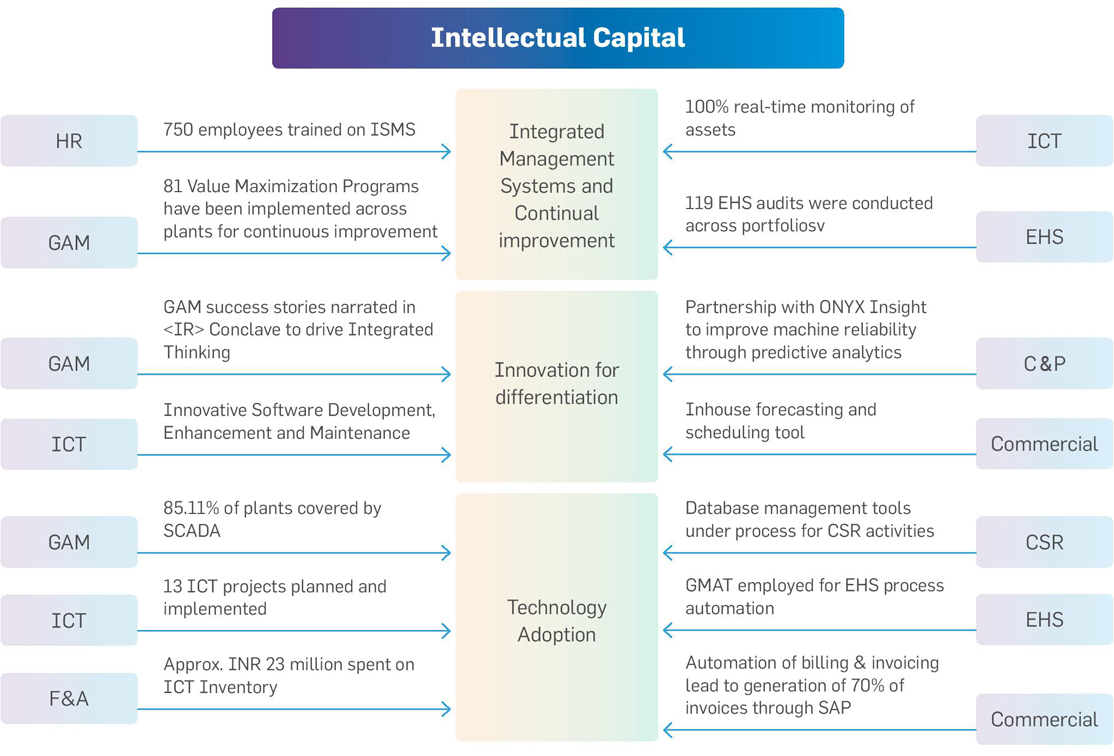

Further to reinforcing natural capital through climate stewardship and circularity, we have made significant strides in intellectual capital through innovation hub interventions and IR conclave. At IR conclaves, last year, the IR champions shared success stories as to how the teams are contributing to the strategic goals of the company and all the six capitals. In this reporting period, six innovation hub sessions were conducted and 150 participants, in 24 groups generated 240 ideas in different functional areas such as engineering and design, business deployment, asset management, procurements, quality, etc. Our digitalization teams are involved in deploying sharing platforms (IEP). They are also extending the deployment of systems to improve asset management by predictive maintenance, remote monitoring and intervention, commercial activity through scheduling and forecasting, and decision making by making real-time information being available at decision points. We believe that organization development through Business Excellence, Digitalization, Innovation, and Systems Assurance is critical for the transformational journey of Greenko.

Our performance and progress on intellectual and natural capital are critical to the generation and distribution of value amongst stakeholders. We are sanguine to engage with you to understand your concerns and expectations with regard to our business and sector.

Chief Operating Officer - Organisation Development

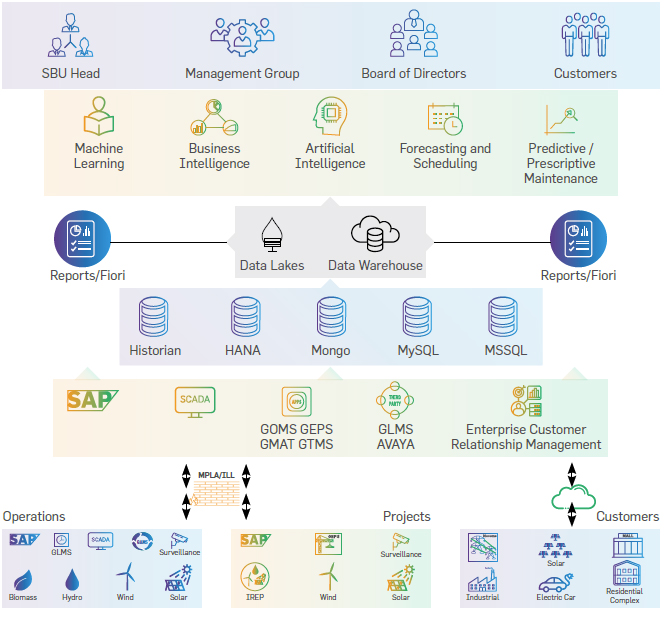

Digitalization and innovation are at the heart of Greenko’s transformation towards decarbonization and decentralization. The greatest transformational potential for digitalization is its ability to break down boundaries between energy sectors, increasing flexibility and enabling integration across entire systems. The result of which is already witnessed globally through improvement in productivity, delivery of firm renewable power, smart demand response, and accessibility.

To harness this potential, Greenko continues to scale up on its innovation and digitization efforts, working towards transforming renewables to reliable, schedulable, and flexible energy through building an Intelligent Energy Platform and Pumped Storage projects for the firm and RTC energy generation, investment in advanced analytics, Internet of Things (IoT) and deployment of systems to improve asset management by predictive maintenance, real-time remote monitoring, and intervention.

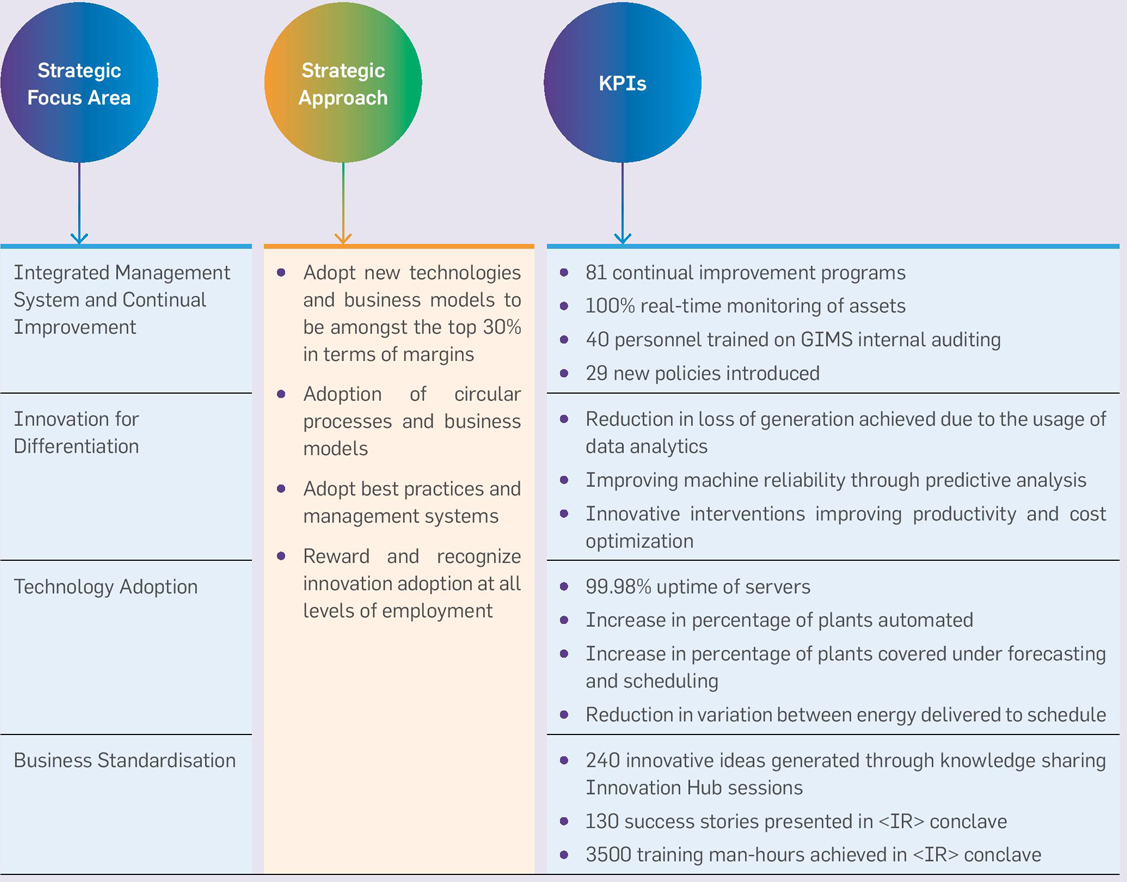

To preserve and enhance value creation of its Intellectual capital, Greenko adopted the following effective strategic approaches viz., Integrated Management Systems and Continual Improvement, Innovation for differentiation, Technology Adoption, Business Process Standardisation. A review of performance on various indicators of intellectual capital demonstrates Greenko’s readiness for effectively establishing an Intelligent Energy Platform which will significantly contribute to the circularity of the economy.

Strategic Direction: Preserve and Enhance Innovation and Systems

Integrated Value Creation in Intellectual Capital

The myriad of challenges associated with decentralization of the energy system, in the form of power quality, flexibility, reliability, improving asset level visibility as well as issues related to cyber security, implementing and integrating variable energy resources, and many more, can be effectively addressed and harnessed through rapid deployment of digitalization and innovative technological advances. In this context, in the current reporting period, Greenko continued to invest in capabilities and expertise that drive the development of technology-enabled and innovative solutions in order to meet the needs of an evolving energy market.

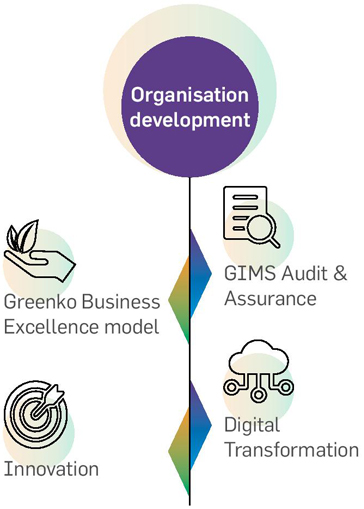

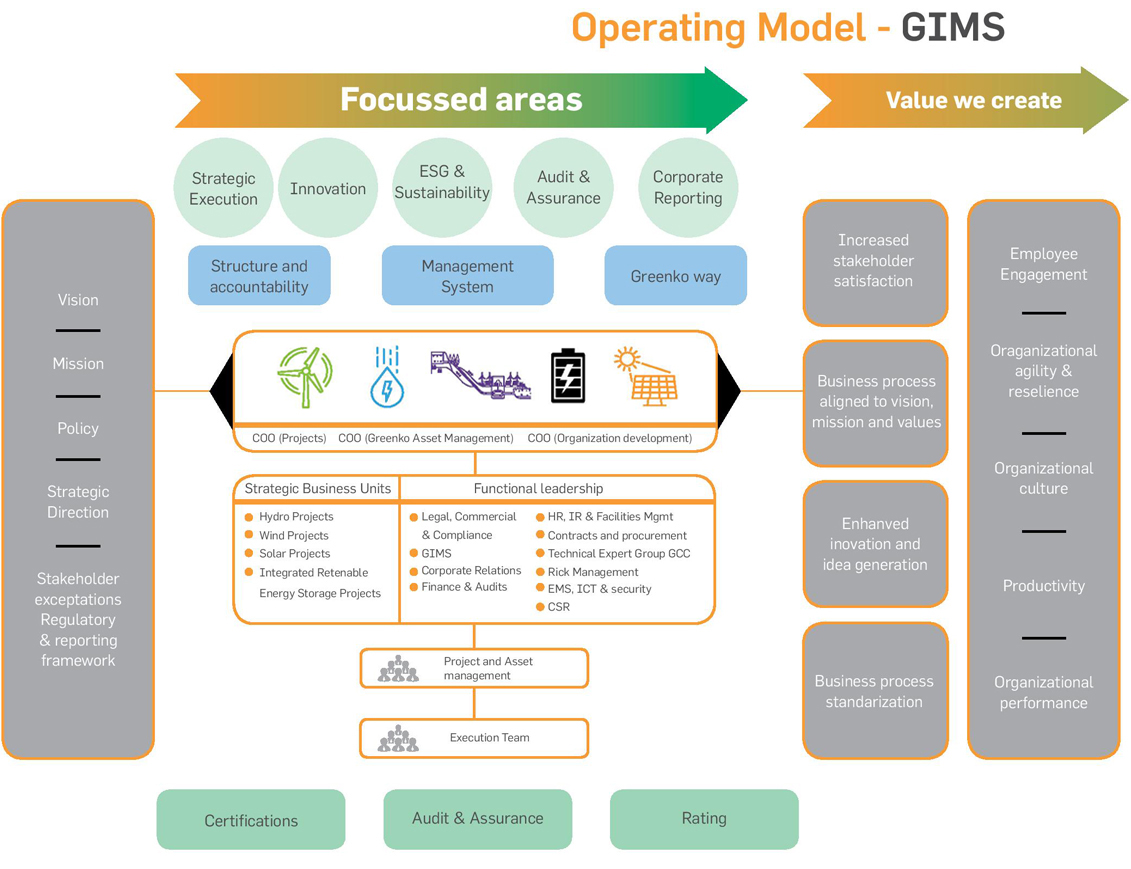

For this purpose, Greenko developed and established in this reporting period a comprehensive Organisation Development process, which encompasses the four key elements that govern its intellectual capital, to build capability and achieve excellence by developing, improving, and reinforcing strategies, structures, and processes. Greenko believes that organization development through Business Excellence, Digitalization, Innovation, and Systems Assurance is critical for its transformational journey. Therefore, the performance of the intellectual capital against these four key elements is monitored and enhanced continuously.

Greenko’s Organisation Development Model

Integrated Management Systems and Continual Improvement

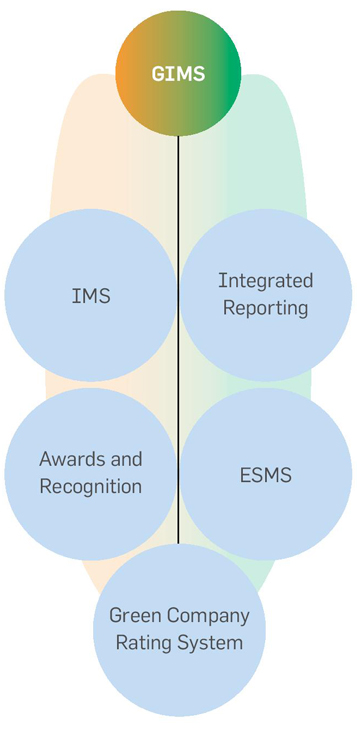

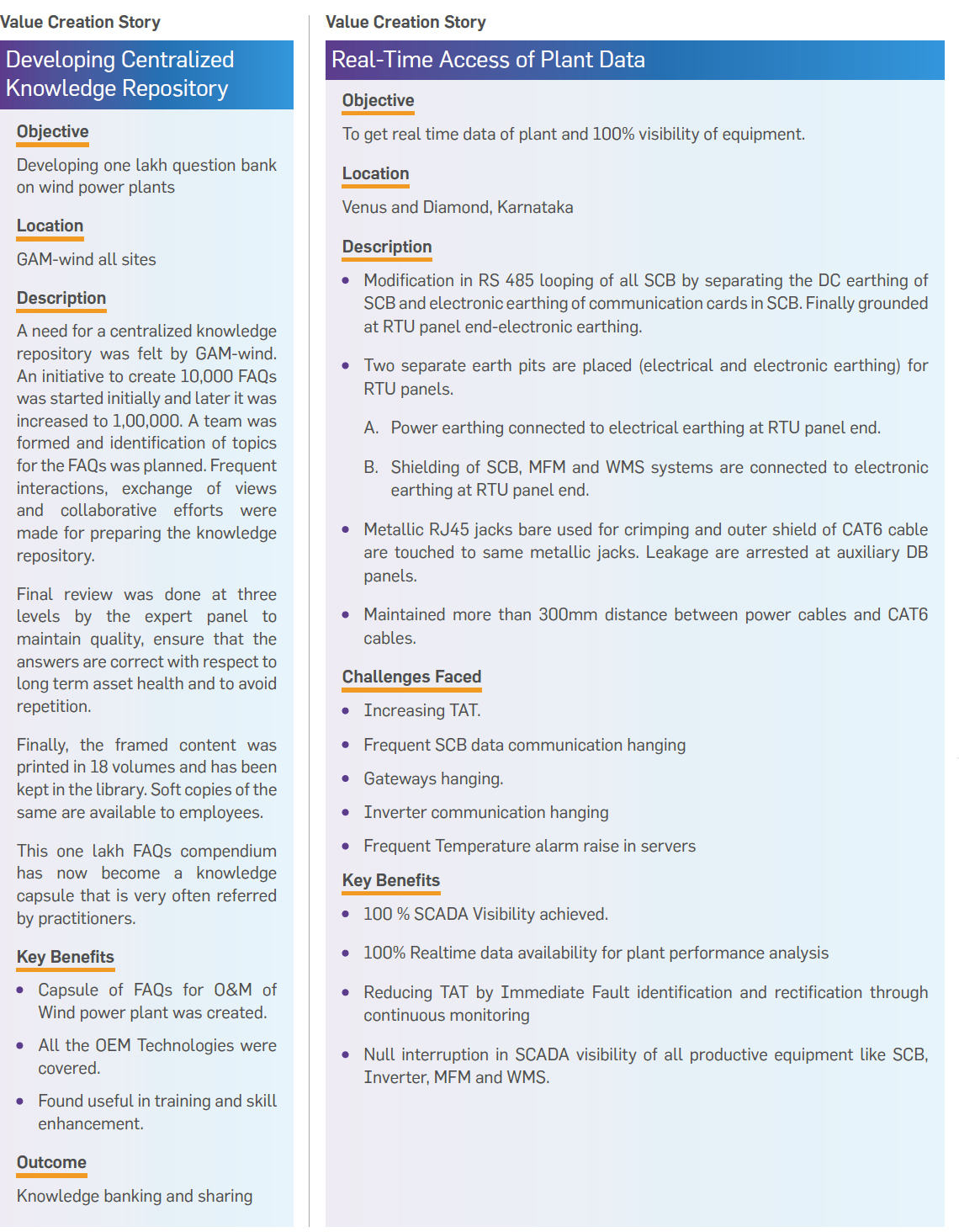

Greenko’s commitment towards continuous improvement and performance excellence prompted the need for an effective management system that is integrated and agile, to respond and grow. For this purpose, Greenko has developed and deployed an Integrated Management System (GIMS) that effectively unifies all the management systems and processes across its operations to standardize, achieve robust process management and sharing, monitoring and controlling systems, forecasting and scheduling delivery, and surveillance among many others.

Greenko Integrated Management System (GIMS) operates in accordance with international standards and industry best practices to effectively align its numerous management systems with their respective strategies, objectives, plans, and operations. It works on the establishment, implementation, integration, and maintenance of Quality, Environment, Health & Safety, Information Security, Energy and Social Accountability Management Systems (QEHS-ISEn- SA) as per the requirements of ISO 9001:2015, ISO 14001:2015, ISO 45001:2018, ISO 27001:2013, ISO 50001:2018 and SA 8000:2014. In addition to ISO standards, the ESMS (Environmental and Social Management Systems) as per the requirements of IFC performance standards, Sustainability reporting as per the requirements of GRI Standards, and Integrated reporting as per the requirements of IIRC are also integrated into GIMS.

Greenko Integrated Management System Structure

GIMS Focused areas

The scope of Greenko Integrated Management System includes certification, auditing, training, implementation and reporting of Integrated Management System (IMS), Environment and Social Management System (ESMS), Green Company Rating System, Integrated Reporting as well as awards and recognition.

The group has deployed diverse systems and associated processes across its operations for project management, asset management, information management and sharing, forecasting and scheduling energy generation, real-time monitoring and control of asset performance, surveillance, etc. All these systems and processes are integrated and managed under GIMS.

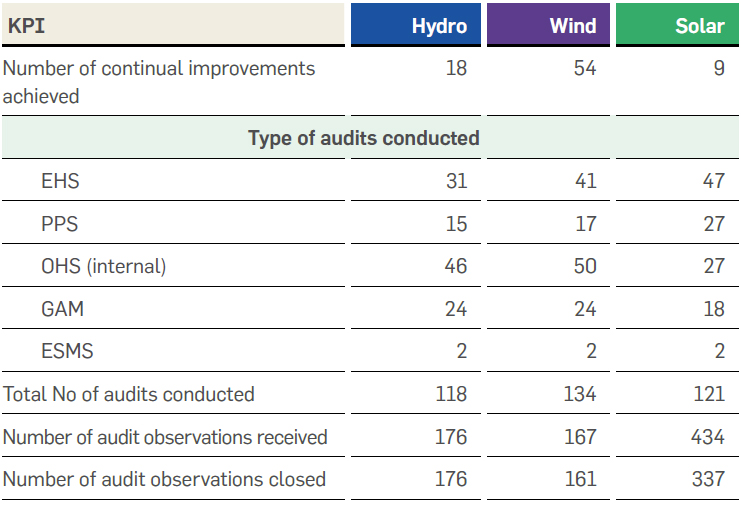

In order to achieve robust performance management and continuous improvement, the deployed management systems and processes are periodically and consistently audited to ensure adherence and effective outcome. The IMS audits are conducted by both internal cross-functional parties and externally. The audit findings are promptly corrected through measures of continuous improvement, upgradation, and advanced technology adoptions.

In the current reporting period, EHS, GIMS, PPS (People, Process, System), OHS, GAM (Greenko Asset Management), and ESMS (Environmental and Social Management system) audits were conducted across portfolios. Contributing to the continual improvement, corrective actions were taken for the audit observations.

GIMS Audit Results across BUs

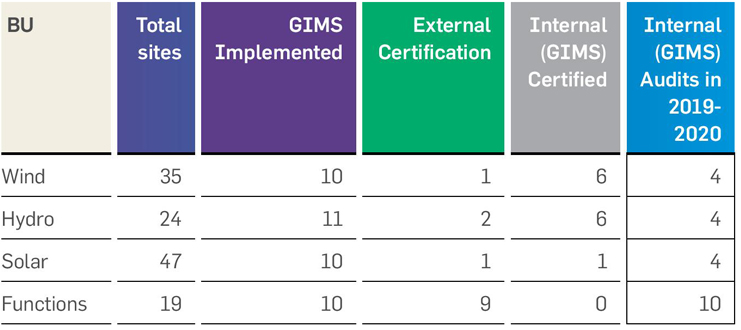

Certification of sites and functions against GIMS

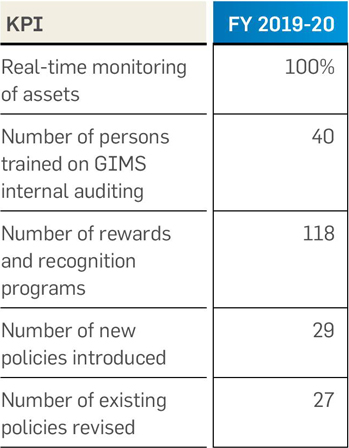

GIMS Performance

Our risk-based

approach to IMS

audits ensure that

the systems and

processes are

strictly adhered to

while the business

is progressing

at breakneck

speed, teams are

more and more

empowered and

innovation is

widespread.

Our risk-based

approach to IMS

audits ensure that

the systems and

processes are

strictly adhered to

while the business

is progressing

at breakneck

speed, teams are

more and more

empowered and

innovation is

widespread.

AVP, GIMS

Innovation for Differentiation

Greenko’s transformation towards GKO 4.0 highly banks on concentrated efforts and investment in promoting innovations and cutting-edge technologies in the operation and maintenance of renewable energy assets.

Integrating renewable energy sources with appropriate storage technologies to provide firm, schedulable and RTC power constituted Greenko’s innovation pursuit for differentiation and competitive advantage. Such innovation included continuous improvements, marginal innovations, adoption of technologies, and planning and implementing innovative projects. In this context, Greenko carried out significant innovative interventions and value maximization programs across projects which effectively improved productivity as well as achieved cost optimization.

Value Creation Story

Value Creation Story

To achieve maximum generation by operating the unit with best Hydraulics.

LocationHemavathy Power & light’s Pvt. Ltd, Karnataka

DescriptionWhile Greenko makes big moves to address the challenges of future energy scenarios, it recognizes the significance of the innovation culture and hence actively promotes it. Greenko rewards innovation at all levels through a variety of innovation awards. In addition to the value-maximizing interventions, Greenko’s pursuit of innovation is addressed through continuous development, deployment, and enhancement of systems, software, and processes. The group has developed and deployed smart data analytics and predictive data simulation measures that enable asset management and tracking of maintenance, real-time and remote monitoring of performance, and collection and smart analysis of data. This helps to substantially maximize the performance of the renewable energy portfolio, reduce O&M costs through predictive maintenance, reduce the frequency of unplanned outages and limit the duration of downtime by rapidly identifying the point of failure.

Data Analytics

Trend Analysis

Statistical and real-time forecasting model

Tracking maintenance activities

Tracking of Assets

Tracking of Projects

Tracking MoM and closing actions

Predictive Measures

Maintenance of assets and Surveillance

Observes health of modules

Machine Learning model

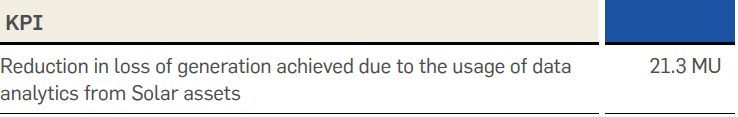

Performance Indicators - Benefits of Data Analytics

In this reporting period, Greenko has partnered with a leading global predictive analytics and engineering firm, ONYX InSight, to improve its turbine reliability through investment in innovative digital technologies.

ONYX Insight is set to modernize 500 of Greenko’s wind turbines through adoption of the latest predictive analytics. Accordingly, sensing equipment are to be installed across 500 direct drive and geared turbines and this will enable online condition monitoring of the turbines. The smart data generated through the predictive analytics will further be used to identify developing machinery failures, thus providing extended lead times of nearly 6 – 12 months to schedule repairs. This self-sufficient operations and maintenance strategy will maximize efficiency, reduce maintenance costs, reduce unplanned downtimes, improve productivity and overall lifespan of the project, in line with Greenko’s circularity principles.

Forecasting and Scheduling

To effectively gauge the rapidly increasing share of renewables, with the variable generation, it is indispensable to have a competent forecasting and scheduling mechanism to maintain flexible and stable energy generation. Therefore, forecasting demand with smart data analytics and scheduling generation accordingly is critical.

In order to deliver reliable power and to meet the regulations of the government to ensure grid stability, Greenko has developed in-house infrastructure and capabilities for forecasting and scheduling of power. F&S activity is carried out by deploying statistical forecasting models and real-time weather forecasts to predict day-ahead energy. Currently, Greenko has partnered with three of the best forecasting agencies to meet the standards set by SLDC. The group’s efforts and deployment of technology have yielded encouraging results in delivering power as scheduled. Greenko’s forecasting accuracy increased from 95% to 98% in the current financial year, thus harnessing the value pool of RE smoothing through accurate forecasting. This capability is indicative and a forerunner to the business transformation designed to harness many new value pools in the energy sector.

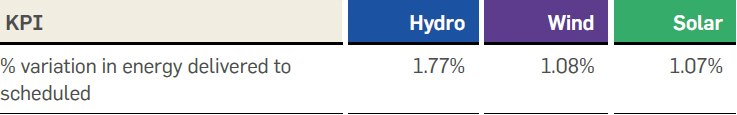

Performance of forecasting and Scheduling

Moving forward, Greenko has set a target to improve the accuracy of the in-house forecast model by using the Global models and integration of forecast platform with SAP S&D by the next financial year.

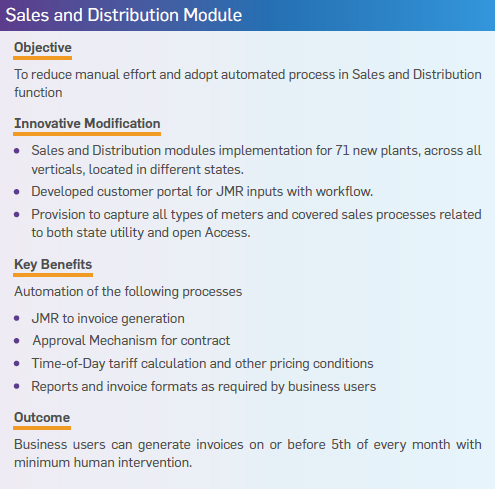

In addition to the forecasting and scheduling tools, the billing and invoicing activity of the commercial department of Greenko is going to be completely automated, as a transformation initiative towards GKO 4.0. In the current reporting period, 70% of the total invoices were generated through SAP. Greenko has targeted to achieve 100% automation of billing and invoicing through SAP in the next financial year.

Systems and Processes deployed across Greenko

Enterprise Information Management SystemSAP S4/HANA

Darwin Box

GEPS (Greenko Energy Project System)

Microsoft SQL Server Integration & Reporting Services provide Asset operational reports on a continuous basis for energy forecasting

Centralized Monitoring & Control Systems (SCADA)GE Proficy: Cimplicity 9, Historian 6.1

Helpdesk

Mind Tree Gladius

The document control mechanism for Plant engineering, design documents, data storage, and department procedures across plants and offices.

Resource Assessment ApplicationsMeteodyn, Meteopole, OpenWind, Wind Farmer, WAsP

Wind Resource assessment software (s) for validating the wind data, Power Curve, identity & selection of wind farms, optimizing the Implementation strategy, validating OEM data trends, and wind forecasting.

PVSyst

Irradiance study, sizing, simulation, and data analysis of Solar PV projects

Collaboration ApplicationsGMAT (Greenko Meeting & Action Tracker)

Technology Adoption

The deep integration between energy transformation and the digital revolution is the future trend of the global energy system. Digital technologies are set to make energy systems around the world more connected, intelligent, efficient, reliable, and sustainable. In this context, Greenko is proactively leveraging digital technologies to improve operations, process automation, boost efficiency, enhance reliability, enable online condition monitoring, and overall, in the way of building intelligent renewable energy projects.

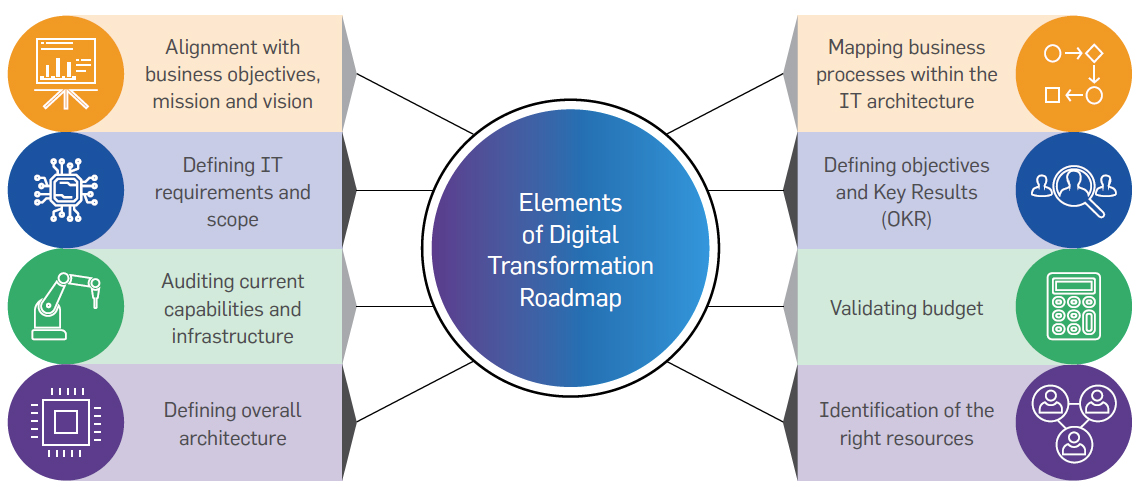

To manage the rapid growth of digitalization and to give it strategic direction within the group, Greenko has established a digital transformation roadmap in the current reporting period. The roadmap is meant to align the digital transformation with the strategic objectives of the organization.

Digitalization Roadmap

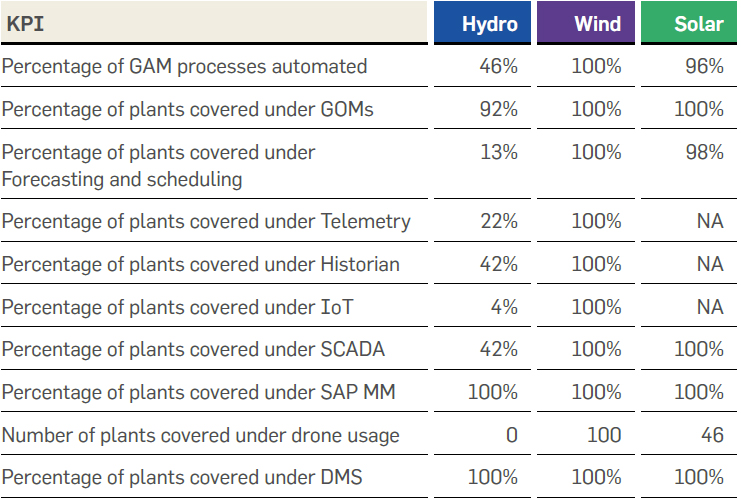

Digitalization at Greenko is achieved through proactively adopting advanced and best in industry technologies such as smart data analytics, predictive data simulation measures, ICT (Information and Communication Technology), Forecasting and Scheduling models, cloud computing, distributed computing, etc. Greenko plants are automated and the assets are monitored using IoT based state-of-the-art SCADA which enables centralized control and real-time monitoring of assets and troubleshooting. Since this is a common sharing platform, it also follows the principle of circularity in Greenko’s business model. Bi -hourly monitoring of remote assets has been established using SCADA and it significantly reduced unplanned downtimes.

Digitalization across BUs

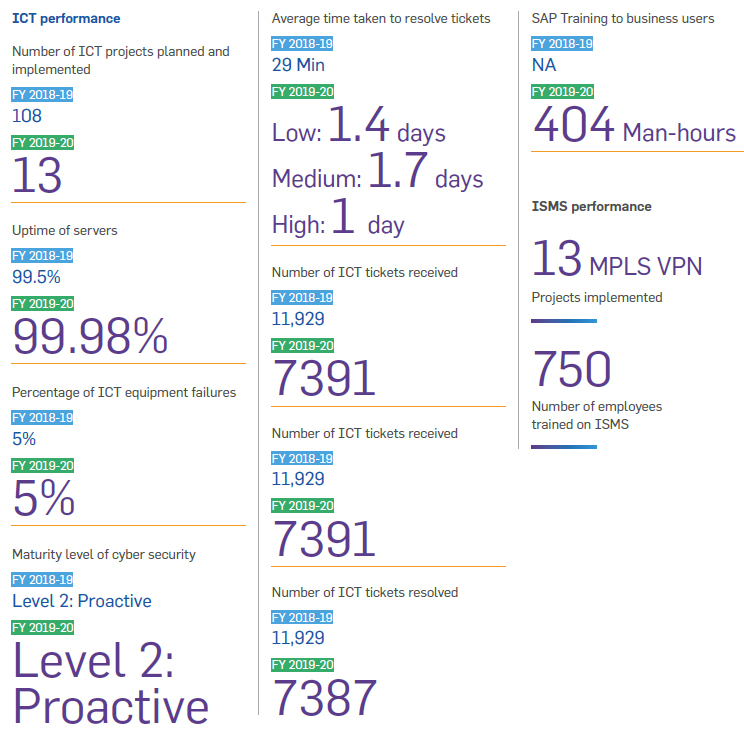

Information and Communication Technology (ICT)

Information and Communication Technology is used at

Greenko to enable seamless real-time information, data

availability for decision making, remote operations and

predictive and adaptive O&M. We have begun adopting

circular approaches in managing ICT assets such as

sharing, reusing after repairs and refurbishing.

Information and Communication Technology is used at

Greenko to enable seamless real-time information, data

availability for decision making, remote operations and

predictive and adaptive O&M. We have begun adopting

circular approaches in managing ICT assets such as

sharing, reusing after repairs and refurbishing.

AVP, ICT

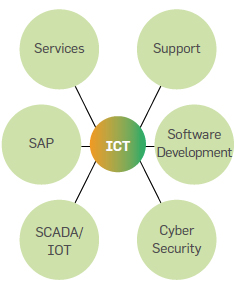

Greenko’s Information and Communication Technology (ICT) focuses on improving performance efficiencies. The main objectives of Greenko’s ICT are as follows

ICT Model

Functions of ICT

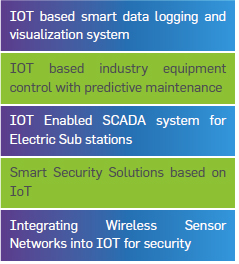

Internet of Things (IoT)/SCADA

In addition to data analytics, Greenko also places great emphasis on the Internet of Things (IoT) in its transformation to digitalization. The possibilities of the Internet of Things (IoT) and Big Data-analytics have revolutionized the future of the energy sector. Along with Greenko’s solid digital infrastructure, IoT allows remote access of data and to maximize the performance of renewable energy portfolios. Greenko has adopted the following IoT based technologies for effective project and asset management.

IoT based Technologies at Greenko

Significant improvements achieved by IoT/SCADA deployment in the current reporting period is as follows,

Software Development

Continuous improvement and excellence in Greenko’s business are achieved through development, deployment, enhancement, and maintenance of systems and software. Innovative software development enables Greenko to be technologicallyenabled, smart, resilient, and dynamic in its transformation journey towards GKO 4.0. In the current reporting period, Greenko has successfully developed the following innovative software,

Ticket generation, management, escalation, transfer, etc. modules effectively deployed for ICT, SAP, HR, CS, and GSS functions

Health Screening FormEmployee Health Screening Form (COVID-19) along with the Control Panel, for both internal and external.

Greenko Forecast and Schedule (GKFS)The system, currently under development, with modules for real-time, forecast, scheduled data, curtailment avoidance, deviation analysis, etc.

Greenko Merchandise Portal (GCART)Comprehensive product information

In addition to new software development, the existing systems and analytical tools are enhanced in line with technological advances and maintained continuously for performance excellence.

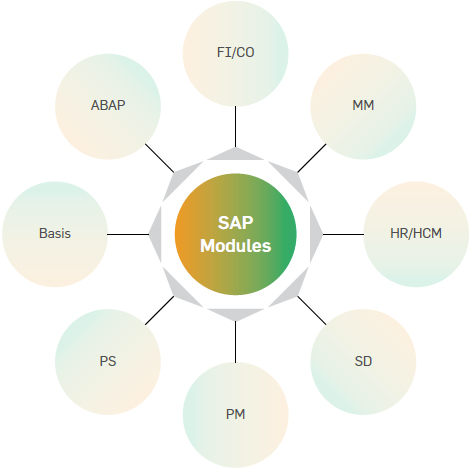

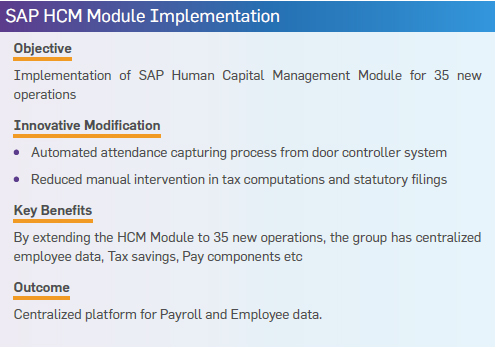

Software Enhancement and MaintenanceSAP Implementation and Management

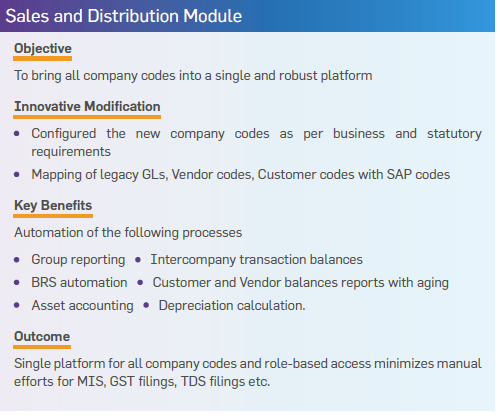

Greenko business processes across departments are effectively automated and digitalized through SAP. The business processes supported and automated by Greenko’s SAP consist of sales orders, invoice process, Procurement, Inventory Management, Vendor Payment, Payroll, and Accounting.

The significant achievements and enhancements of SAP in the current reporting year as follows,

Value Creation Story

Value Creation Story

Value Creation Story

Information Security Management

According to the International Energy Agency, “Digitalization is already improving the safety, productivity, accessibility, and sustainability of energy systems. But digitalization is also raising new security and privacy risks.” Increased integration of digitalization in Greenko’s processes and its growth towards an Intelligent Energy Platform makes information security imperative for the group.

Information security is ensured and highly prioritized in Greenko by means of its effective Information Security Management System (ISMS) which is integrated into GIMS. The scope of the Information Security System extends to all information used at Greenko Group, in all formats, regardless of the specific departments and individuals that own and manage the information at a local level. This includes information owned or processed by other organizations but relevant in their dealings with Greenko Group.

While the focus of information security capabilities is provided by the Information Security function, a number of additional departments including Legal and Registry include explicit information responsibilities and are therefore considered a part of Information security. The Information Security function provides and coordinates expertise to influence the information security approach of the Greenko Group, helping it to achieve its strategic objectives by ensuring the availability, confidentiality, and integrity of information. By recognizing the different types of information used, and the business requirements associated with each, Greenko will deliver a secure framework within which it can provide flexibility to suit organizational needs while maintaining compliance with legal obligations and sector-specific best practice.

In addition, the significant improvements achieved through ICT services and support, in the current reporting period, is as follows,

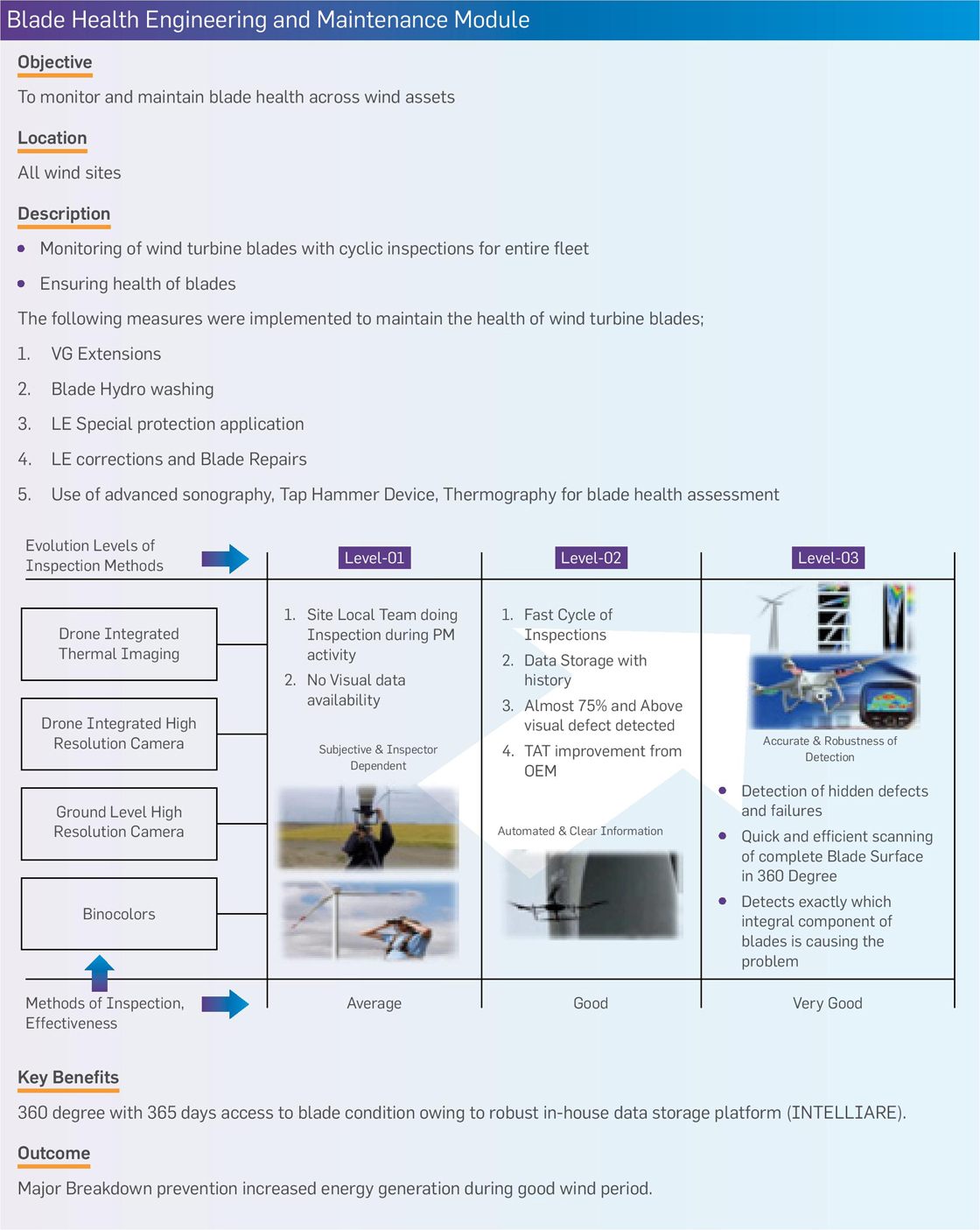

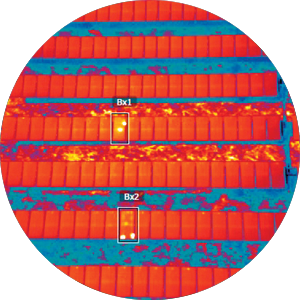

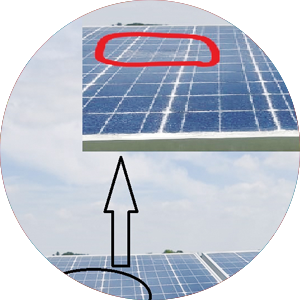

The use of drones at Greenko has created an array of new opportunities in monitoring, operation and maintenance of Wind, Solar and Hydro assets.

Greenko has augmented drones with advanced technologies like artificial intelligence, machine learning, data analytics enabling seamless real-time information, data availability for decision making, remote operations, predictive and adaptive Operations & Maintenance and agile project management.

Solar panels require frequent inspections to monitor their performance, as they develop issues that are difficult to detect manually due to the size of the solar farms. Also, Wind turbine generators, gearboxes and blades require frequent inspections as they can develop cracks, fissures, and other structural issues over time that can affect its efficiency. They need periodic inspections to detect any issues. Detecting these issues and defects earlier was more time and money consuming.

Instead of manually inspecting and using a handheld thermal camera to detect defects and issues, Greenko is using drones equipped with a thermal camera to perform the inspections which improved the accuracy and quality of data radically faster. A drone with a zoom camera can view parts of the solar panels, wind turbines and blade. Thermal imaging capabilities will be able to detect any other issues with either the solar panels, wind turbine generators, gearboxes or blades.

Drone Operations involves –

a. Planning and acquiring data to create flight plans, orient field teams and operate drones to collect imagery and thermal data.

b. Process data using analytics, machine learning, artificial intelligence and proprietary algorithms to analyze and validate the data to ensure accuracy and quality

c. Actionable insights derived from the above reports and delivered to GAM operations/Project Hub for further action/follow-up at sites

GAM operational Centre

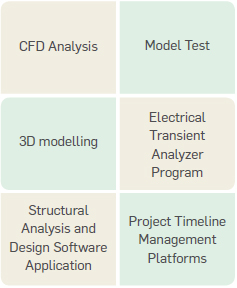

Technology Adoption in IRESP

Innovation and technology adoption is at the very core of Greenko’s shift from generation-based delivery to smart demand-based delivery through the development of Integrated Renewable Energy Projects supported by an Intelligent Energy Platform. The various technological tools that are employed in the engineering and design phase of IRESP are as follows,

Technological Tools Employed for IRESP Design

With the aim of standardizing business practices, the organisation has established Greenko Integrated Management Systems. GIMS is an instrument established to drive standardisation of processes across the operations of the group, in line with Greenko’s values of compliance and ethics and in conformance with global standards. Digitalization of business processes and audits are results of this process standardization.

GIMS aims to make the business processes in the organization uniform through the standardization process to ensure that Greenko performs the same activity in the same way at different places. In this context, under GIMS framework, Greenko’s critical processes such as Asset Management, Project Management, Quality Assurance and Control, Occupational Health and Safety, Environment and Social Management, Information Security etc. are standardised and continuously improved, in line with industry best practices.

Under the framework of GIMS, all functions of Greenko have started implementing PPS and Ownership model, originally established to strengthen human capital, to standardize the process outcomes, and to own the decision-making process involved.

Business Process Standardisation at Greenko

Greenko Integrated Management System (GIMS)

Greenko’s robust integrated management system seamlessly standardizes the diverse systems and processes employed so that they are in line with the organization’s objectives and maintains the business through an ever-changing environment. It offers best-practice guidance for operational excellence, increased efficiency, and cost optimization.

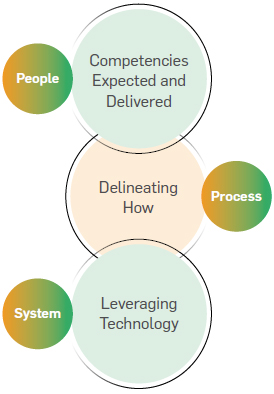

People, Process, and System (PPS) framework

The People, Process, and System framework of Greenko supplements GIMS in the management of assets and projects. The PPS was first deployed for Asset Management at Greenko. The objective of PPS deployment at GAM is to uplift the performance of the assets by way of synergizing the processes with no compromise on the essential elements like EHS. Under the framework, GAM was divided into seven key areas for which detailed processes were delineated, discussed, and adopted in these key areas.

Components of People, Process, System framework

The PPS framework operates on the context that Greenko’s transformation towards GKO 4.0 is possible and seamless only when people own and steer, processes are clear and understood and systems enable people to adhere and use processes for organizational objectives.

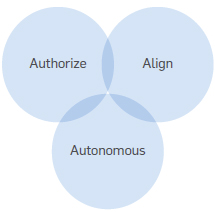

Ownership Model

Greenko’s ownership model was established with the goal to create an empowered team with accountability, authority, and autonomy to achieve business goals in line with organizational values. Under the ownership model, Greenko’s teams are provided with several “not-the-way” illustrations to prevent them from making wrong decisions and have access to all relevant information.

Key concepts of Ownership Model

Driving Innovation

Greenko has instituted an Innovation Hub which is essentially a knowledgesharing platform in which innovative ideas are conceived and shared among different functional areas through participative sessions, in the current reporting period. This progressive initiative is a critical component of Greenko’s Organisational development and significantly contributes to and is a major driving force of the transformation journey towards GKO 4.0.

The purpose of the Innovation Hub is to identify the gaps and improvement opportunities in Projects and Operations of Greenko. The methodology employed for the Innovation Hub enables the participants to identify and analyse the important issues, gaps, opportunities, and improvement areas in the organization and subsequent preparation of an action plan to resolve the issues identified. The establishment of an Innovation Hub is a critical step towards Greenko’s innovation culture.

Key Results of Innovation Hub

In FY2019-20, six innovation hub sessions were conducted and 150 participants, in 24 groups generated 240 ideas in different functional areas such as engineering and design, business deployment, asset management, procurements, quality etc. This signifies the Co-creative culture at Greenko.

Deployment of Integrated thinking

Greenko is continuously defining, implementing, measuring, and communicating its value creation and business strategy throughout the organization, year on year. To communicate further down and deploy the business strategy and value creation model, Greenko has launched <IR> Conclave, as the annual platform to engage its stakeholders at the sites and functions. These IR conclaves have become one of Greenko’s flagship events attracting diverse stakeholders from GAM-Wind, Solar & Hydro and other functions from the corporate office. It brings all of them to a common platform.

These IR Conclaves have endeavoured to

highlight the direction that Greenko has

taken to reach its goals. The objective of

this

In the current reporting period, the

Performance Highlights of

Success Stories

Award-Winning Stories

Training Man-Hours